Curved surface FSS radar cover preparation method based on metal mask plate and thermal spraying technology

A metal mask and radome technology, which is applied in metal processing equipment, metal material coating technology, coating, etc., can solve the problems of cumbersome preparation process, inability to be directly applied, unfavorable electromagnetic wave passage, etc., achieve high flexibility, solve processing problems, etc. Difficult and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

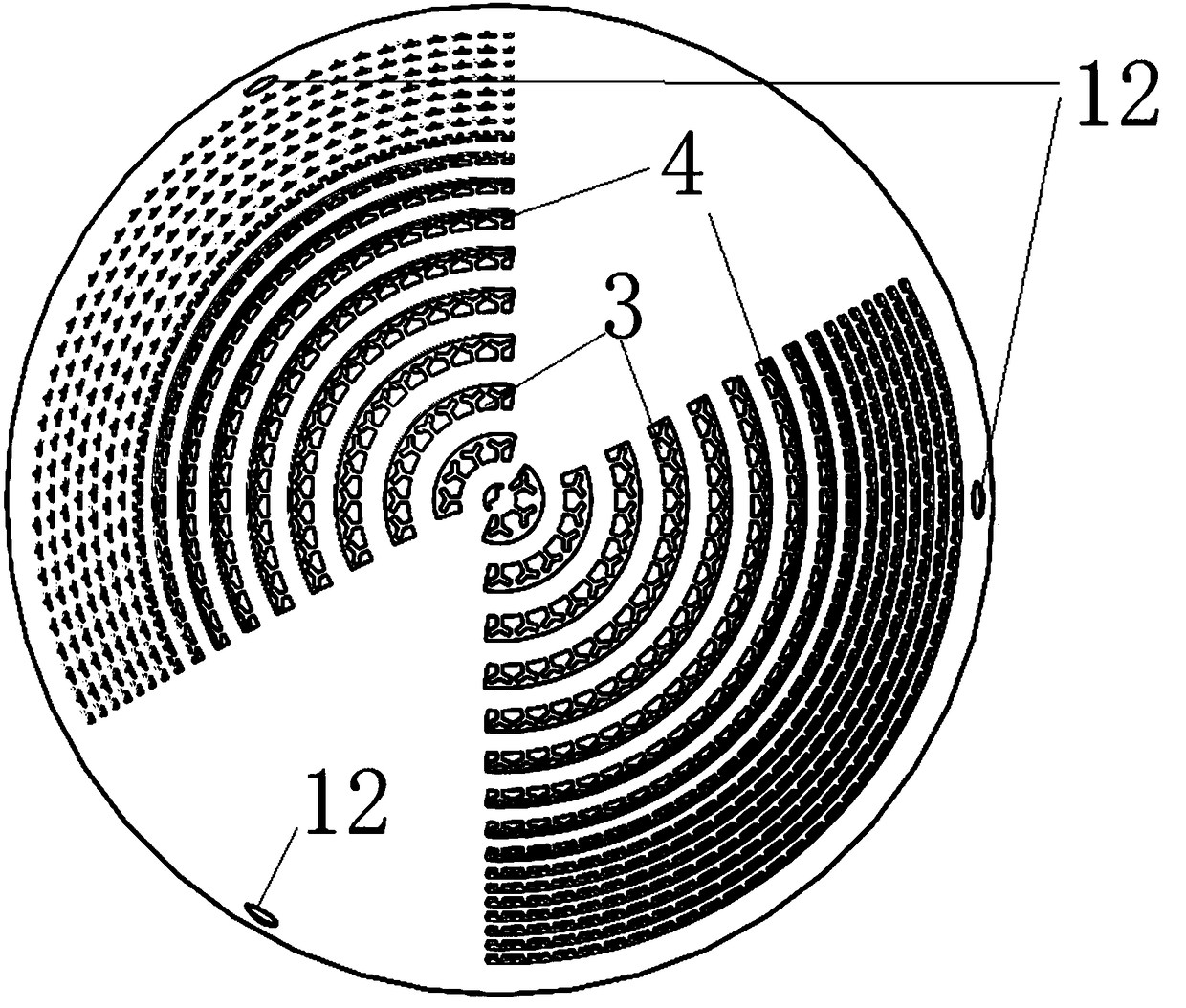

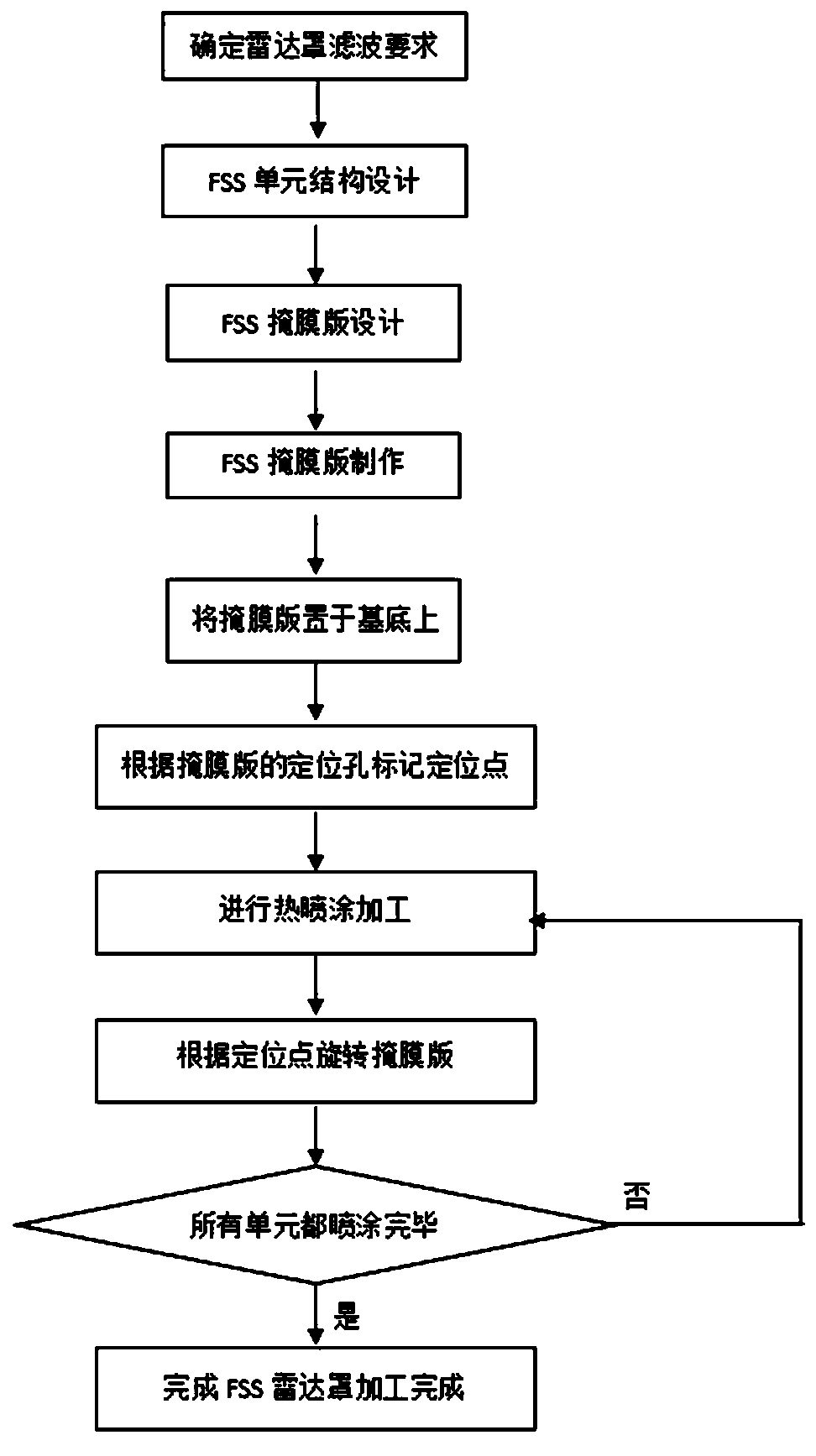

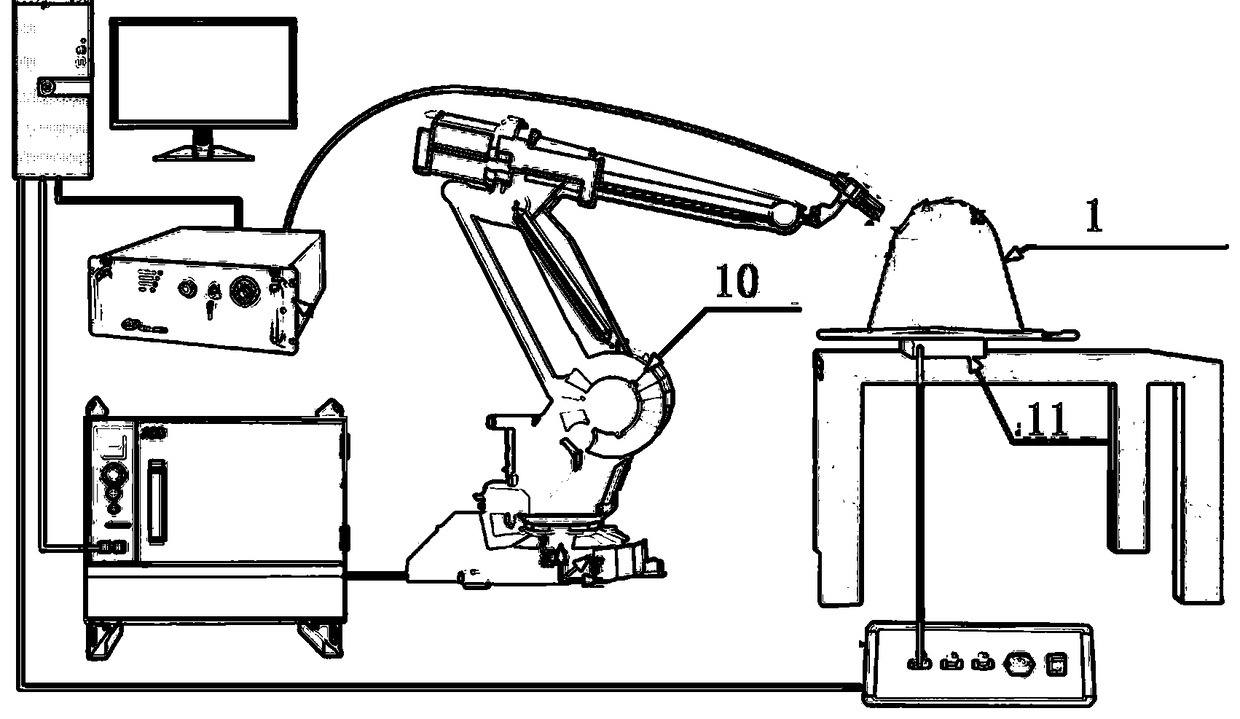

[0036] Such as Figure 1-7 As shown, the method for preparing a curved FSS radome based on a metal mask and thermal spraying technology, the preparation method includes a FSS curved mask 1, which includes a hollow structure 8 matching the design shape of the FSS layer 6 on the surface of the radome 5, The inner wall of the mask plate 1 conforms to the surface of the radome 5. When preparing a curved FSS radome, the FSS curved mask plate is covered on the surface of the radome to form a combination, and then the surface of the combination is sprayed with thermal spraying equipment, and the surface of the radome is sprayed on the mask plate. A metal-containing FSS layer conforming to the shape is formed on the surface of the radome at the hollowed out portion.

[0037] The FSS layer 6 is composed of a plurality of FSS units 2 distributed on the surface of the radome 5; the mask plate is provided with a complementary structure 7 corresponding to the FSS layer 6; the hollow struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com