Preparation method and application of modified composite pigment yellow

A composite pigment and modification technology, which is applied in the field of preparation of modified composite pigment yellow, can solve the problems of affecting the modification effect, low bonding stability, easy separation, etc., and achieve the effect of preventing secondary aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) put 16.2gFeCl 3 , 24.2gFe(NO 3 ) 3 Add it into purified water, stir at 50-60°C until completely dissolved, add 4g NaOH, stir at 80-90°C for 1 hour, a large amount of colloids are precipitated in the solution, cool to room temperature, centrifugally filter to obtain ferric hydroxide colloid, and then transfer to -10°C environment Sealed and frozen for 2 hours, and made into fine powder by ultra-fine pulverizer, and finally made into nano-powder by nano-grinder;

[0021] (2) Take 50 mL of water, 3.6 g of 30% hydrochloric acid solution, add 3.6 g of 3,3-dichlorobenzidine under stirring, continue stirring for 3 minutes, add 0.4 g of aminotriacetic acid, heat up to 90 ° C, stop heating, and stir After cooling to 40°C, 6.4 g of 30% hydrochloric acid was added, and the temperature was lowered to 0°C. Then add 6.4g of 30% sodium nitrite solution to carry out the diazotization reaction. The reaction process is completed within 2 minutes. After the reaction is completed, d...

Embodiment 2

[0028] (1) put 16.2gFeCl 3 , 24.2gFe(NO 3 ) 3 Add it into purified water, stir at 50-60°C until completely dissolved, add 4g NaOH, stir at 80-90°C for 1 hour, a large amount of colloids are precipitated in the solution, cool to room temperature, centrifugally filter to obtain ferric hydroxide colloid, and then transfer to -10°C environment Sealed and frozen for 2 hours, and made into fine powder by ultra-fine pulverizer, and finally made into nano-powder by nano-grinder;

[0029] (2) Take 50 mL of water, 3.6 g of 30% hydrochloric acid solution, add 3.6 g of 3,3-dichlorobenzidine under stirring, continue stirring for 3 minutes, add 0.4 g of aminotriacetic acid, heat up to 90 ° C, stop heating, and stir After cooling to 40°C, 6.4 g of 30% hydrochloric acid was added, and the temperature was lowered to 0°C. Then add 6.4g of 30% sodium nitrite solution to carry out the diazotization reaction. The reaction process is completed within 2 minutes. After the reaction is completed, d...

Embodiment 3

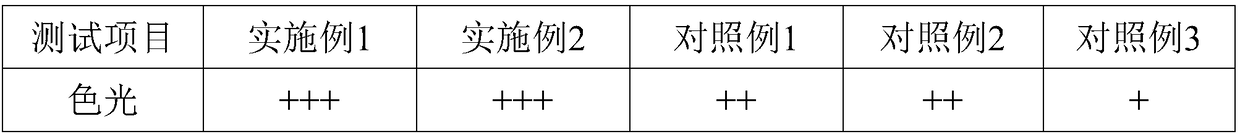

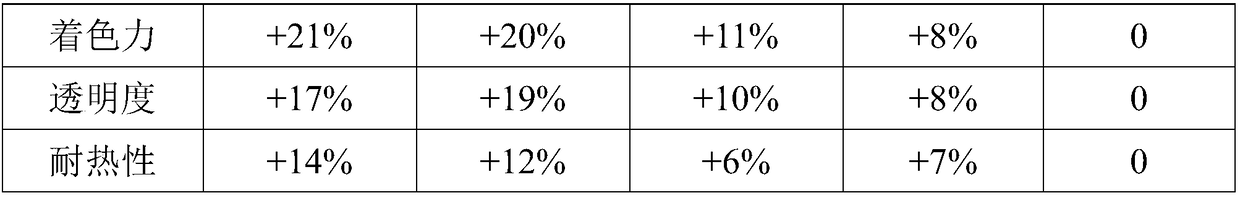

[0056] Utilize embodiment 1, embodiment 2 to make the powder coating with modified composite pigment yellow as raw material, and set without adding catalyst PdCl 2 Comparative example 1, the comparative example 2 using non-ionic surfactant OP-10 instead, the comparative example 3 of making powder coatings with 8323 yellow as raw material, and carry out relevant comparison to embodiment 1-2, comparative example 1-3 The coating performance test results are shown in Table 1.

[0057]Table 1 Performance testing of powder coatings

[0058]

[0059]

[0060] In Table 1, taking Comparative Example 3 as the standard product, the test data in Example 1-2 and Comparative Example 1-2 are all detected on the basis of the standard product. It can be found from the data in the table that the performance of the powder coating prepared by the modified and compounded pigment has been greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com