A kind of preparation method and application of styryl phosphonic acid monoester

A technology of styryl phosphonic acid monoester and styrene, which is applied in the field of preparation of styryl phosphonic acid monoester, can solve the problem that the by-product thionyl chloride is difficult to handle, there is no mineral flotation collector, and equipment requirements are relatively low. Advanced problems, to achieve the effects of suppressing side reactions, good foaming performance, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

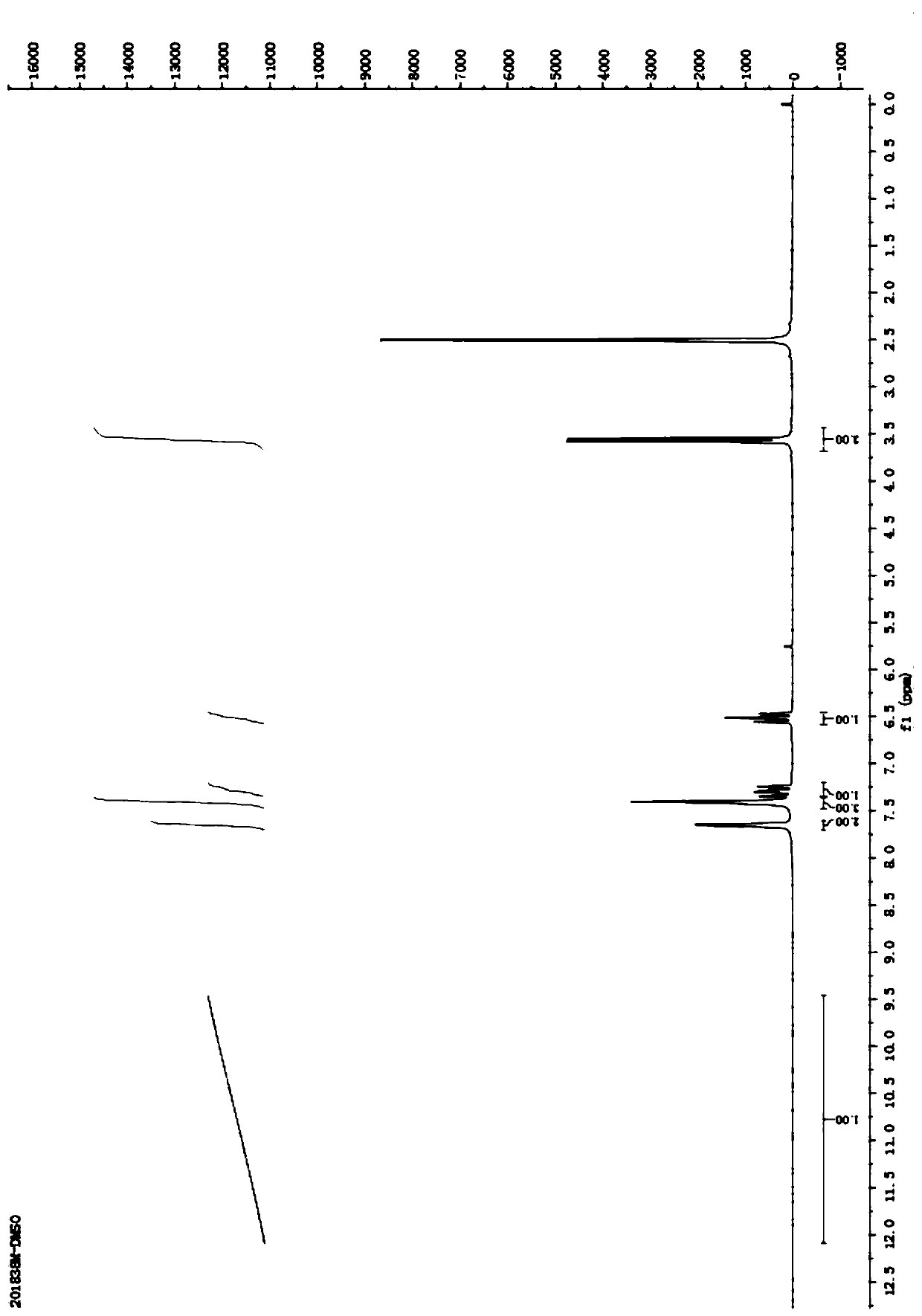

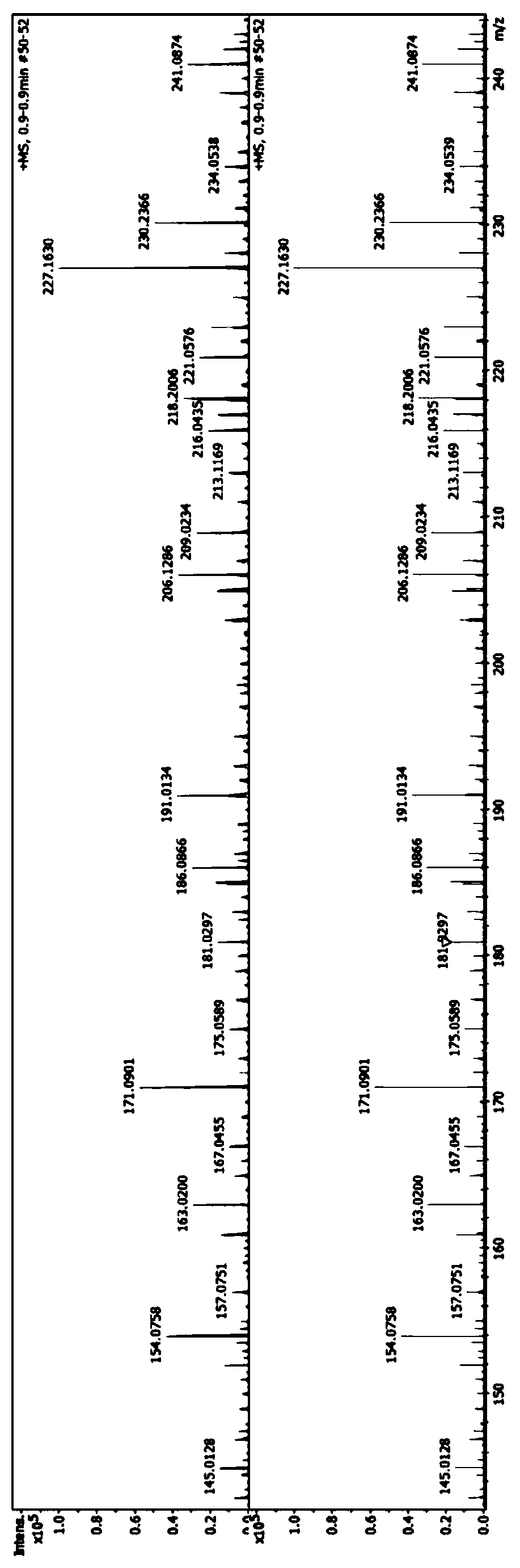

Embodiment 1

[0047] Take 20.8g of phosphorus pentachloride with a purity of 98% and add it to 80ml of chloroform with a purity of 99.8%, stir it in a water bath at 50°C to dissolve it; take 10.4g of styrene with a purity of 99%, dissolve it in 20ml of trichloromethane In methane, add dropwise to the above-mentioned phosphorus pentachloride solution, and fully stir for 4 hours under the condition of 50°C water bath; take 3.84g of methanol with a purity of 99.8% and dropwise into the above-mentioned reaction solution, and fully stir for 1h under the condition of 50°C water bath; 50ml of distilled water was added dropwise to the above reaction solution, and fully stirred for 1 hour under the condition of 50°C water bath. After the reaction is over, separate the liquid in the separatory funnel, remove the upper aqueous phase, add 20ml of NaOH solution with a concentration of 40% to the organic phase, shake fully, leave to stand for stratification, take the upper saponified phase, add 40ml of 5m...

Embodiment 2

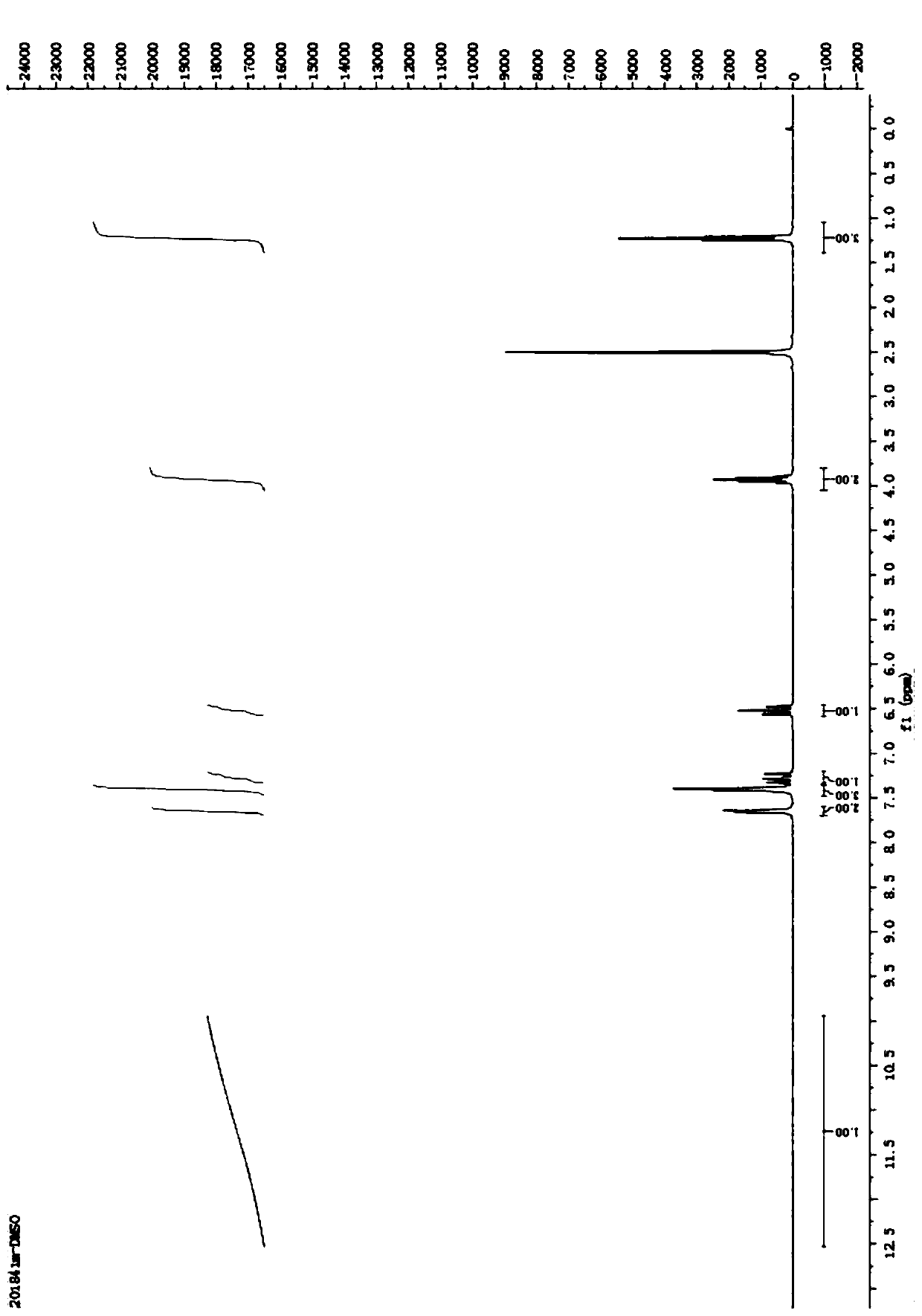

[0049] Take 20.8g of phosphorus pentachloride with a purity of 98% and add it to 80ml of chloroform with a purity of 99.8%, stir it in a water bath at 50°C to dissolve it; take 10.4g of styrene with a purity of 99%, dissolve it in 20ml of trichloromethane In methane, add dropwise to the above-mentioned phosphorus pentachloride solution, and fully stir for 4 hours under the condition of 50°C water bath; take 5.52g of ethanol with a purity of 99.8% and dropwise into the above-mentioned reaction solution, and fully stir for 1h under the condition of 50°C water bath; 50ml of distilled water was added dropwise to the above reaction solution, and fully stirred for 1 hour under the condition of 50°C water bath. After the reaction is over, separate the liquid in the separatory funnel, remove the upper aqueous phase, add 20ml of NaOH solution with a concentration of 40% to the organic phase, shake fully, leave to stand for stratification, take the upper saponified phase, add 40ml of 5mo...

Embodiment 3

[0051] Take 20.8g of phosphorus pentachloride with a purity of 98% and add it to 80ml of chloroform with a purity of 99.8%, stir it in a water bath at 50°C to dissolve it; take 10.4g of styrene with a purity of 99%, dissolve it in 20ml of trichloromethane In methane, add dropwise to the above phosphorus pentachloride solution, fully stir for 4h under the condition of 50°C water bath; take 8.88g of n-butanol with a purity of 99.8% and dropwise into the above reaction solution, fully stir for 1h under the condition of 50°C water bath ; Take 50ml of distilled water and add dropwise to the above reaction solution, and fully stir for 1 hour under the condition of 50°C water bath. After the reaction is over, separate the liquid in the separatory funnel, remove the upper aqueous phase, add 20ml of NaOH solution with a concentration of 40% to the organic phase, shake fully, leave to stand for stratification, take the upper saponified phase, add 40ml of 5mol / L was acidified with hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com