Phosphorus-containing mesoporous carbon material, method for preparing same and application of phosphorus-containing mesoporous carbon material

A technology of mesoporous carbon and pore size, which is applied in the field of phosphorus-containing mesoporous carbon materials and its preparation, can solve the problems of cumbersome synthesis process, expensive synthesis cost, and difficulty in popularization, and achieve convenient operation, simple process, and good mesoporous structure and application performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of soluble resin precursor: Add 9.2 g of phenol into a single-necked flask and place it in a 43°C water bath to melt, then add 1.95 g of 20% NaOH aqueous solution by mass percentage, stir for 10 minutes, and then add 16.3 g of formaldehyde solution (37wt% ), reflux at 71 °C for 1 h, and cool to room temperature. Adjust the pH to about 7 with 2 M hydrochloric acid solution, place the flask in a 50°C water bath to distill off water under reduced pressure, add 5.0 g of absolute ethanol, and centrifuge to remove NaCl crystals. The flask was placed in a 48 °C water bath to distill off ethanol under reduced pressure, and after cooling to room temperature, it was configured into a 20 wt% ethanol solution.

Embodiment 2

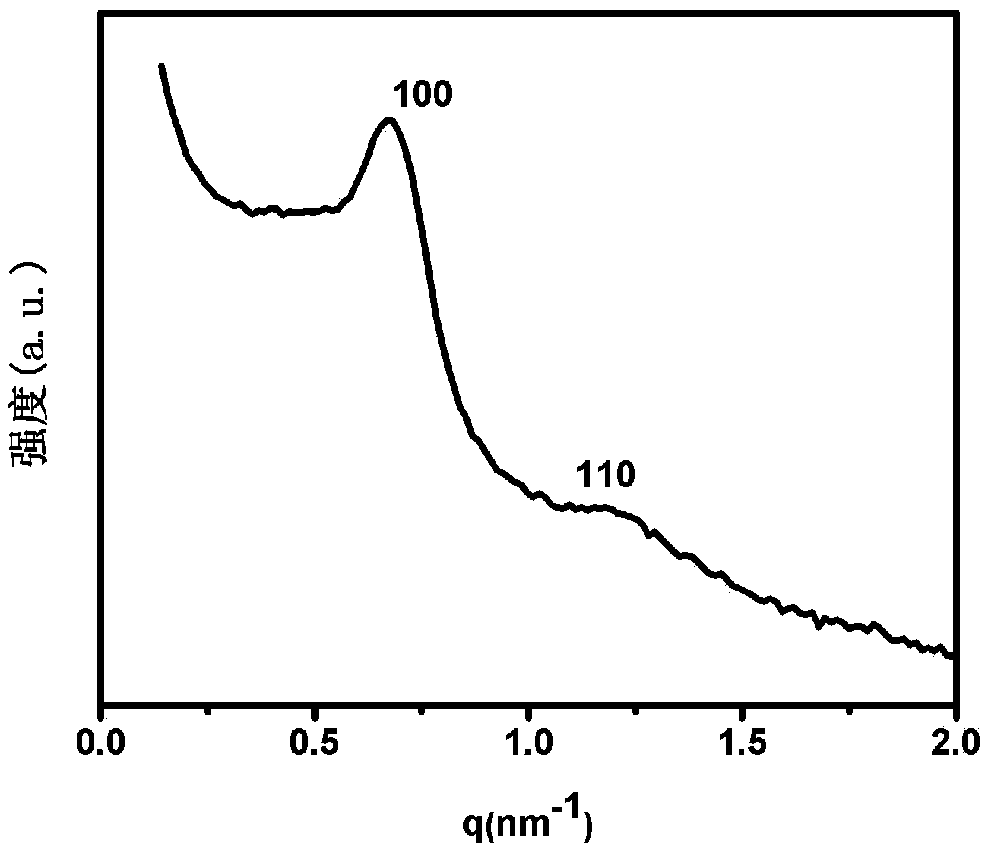

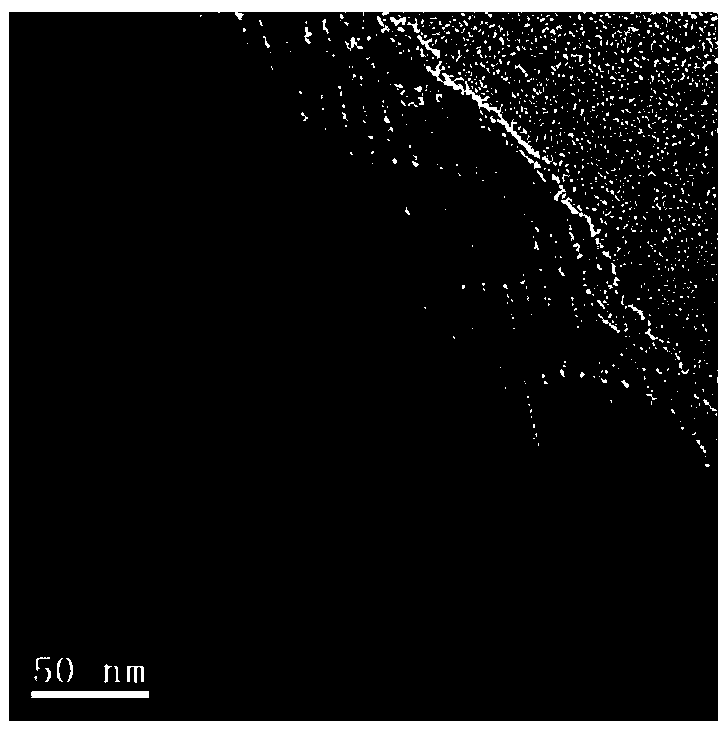

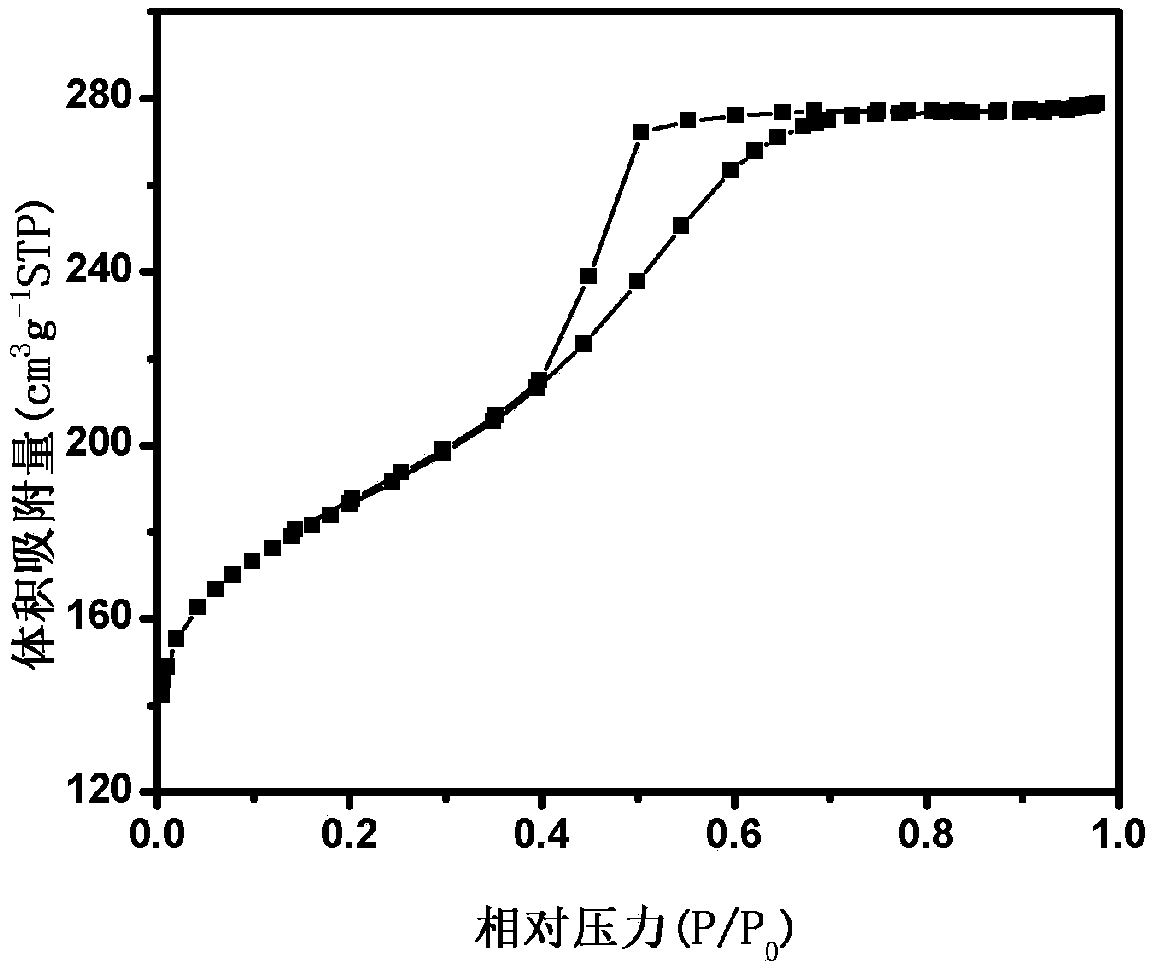

[0045] Phosphorus-containing mesoporous carbon materials were prepared using triethylphosphate as a phosphorus precursor: 5.0 g of nonionic surfactant polyethylene oxide–polypropylene oxide–polyethylene oxide triblock copolymer (F127) was dissolved in Obtain clear solution in 50.0 g absolute ethanol, then add the phenolic resin ethanol solution of 20 wt% prepared in 25.0 g embodiment 1 and 1.2 g triethyl phosphate, stir and mix for 30 minutes; Then spread this mixed solution evenly on culture In a dish, stand at room temperature for 8 hours and then transfer to a 100°C oven for low-temperature curing for 24 hours; the obtained phosphorus-containing resin-nonionic surface active composite material is carbonized at a high temperature of 800°C for 3 hours under the protection of a nitrogen atmosphere to obtain a phosphorus-containing mesoporous carbon material . The heating rate during high temperature carbonization is 5°C / min. The phosphorus content of the obtained phosphorus-c...

Embodiment 3

[0047] Phosphorus-containing mesoporous carbon materials were prepared using triethylphosphate as a phosphorus precursor: 5.0 g of nonionic surfactant polyethylene oxide–polypropylene oxide–polyethylene oxide triblock copolymer (F127) was dissolved in Obtain clarified solution in 50.0 g dehydrated alcohol, then add the phenolic resin ethanol solution of 20 wt% prepared in 25.0 g embodiment 1 and 7.8 g triethyl phosphate, stir and mix for 30 minutes; Then spread this mixed solution evenly on culture In a dish, stand at room temperature for 8 hours and then transfer to a 100°C oven for low-temperature curing for 24 hours; the obtained phosphorus-containing resin-nonionic surface active composite material is carbonized at a high temperature of 800°C for 3 hours under the protection of a nitrogen atmosphere to obtain a phosphorus-containing mesoporous carbon material . The heating rate during high temperature carbonization is 5°C / min. The obtained phosphorus-containing mesoporous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com