Preparation method and application of a two-dimensional lateral polymer heterojunction visible light-responsive catalytic hydrogen production material

A polymer, heterojunction technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. The problems of high exciton binding energy and slow transfer rate of photogenerated carriers can improve the photocatalytic effect and reduce the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

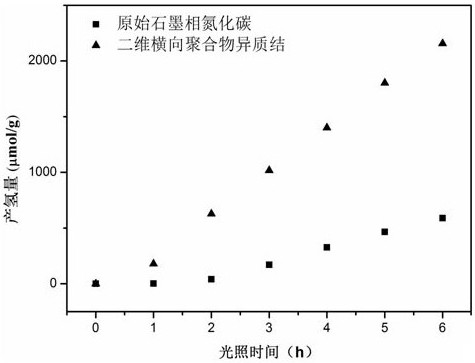

[0018] 10 g of melamine was added to 50 mL of phenanthrene in methanol solution, stirred at room temperature for 2 h, and then ultrasonically dispersed for 50 min. The power of ultrasonic dispersion was controlled at 100 W, and the temperature of ultrasonic dispersion was controlled at 40 °C. Afterwards, it was transferred to a drying oven at 60 °C for 10 h. After complete drying, it was calcined in a muffle furnace at a heating rate of 15 °C / min. During the heating process, the temperature was maintained at 300 °C for 1 h and at 400 °C for 1 h. h, keep the temperature at 550 °C for 4 h, wash with deionized water 5 times after cooling, and dry at 60 °C for 12 h. heterojunction materials. The hydrogen production of the two-dimensional heterojunction material prepared by the present invention is as high as 2156 μmol / g after being irradiated for 6 hours under a xenon lamp light source, which is about 4 times the hydrogen production of pure graphite phase carbon nitride.

[0019]...

Embodiment 2

[0022] 10 g of melamine was added to 25 mL of phenanthrene in methanol solution, stirred at room temperature for 2 h, and then ultrasonically dispersed for 50 min. The power of ultrasonic dispersion was controlled at 100 W, and the temperature of ultrasonic dispersion was controlled at 40 °C. Afterwards, it was transferred to a 60°C oven for drying for 10 h. After complete drying, it was calcined in a muffle furnace at a heating rate of 15°C / min. During the heating process, the temperature was kept at 300°C for 1 h, and at 400°C for 1 hour. h, keep the temperature at 550°C for 4 h, and other operations are the same as in Example 1. The resulting photocatalytic hydrogen production was 1314 μmol / g.

Embodiment 3

[0024] 10 g of melamine was added to 75 mL of phenanthrene in methanol solution, stirred at room temperature for 2 h, and then ultrasonically dispersed for 50 min. The power of ultrasonic dispersion was controlled at 100 W, and the temperature of ultrasonic dispersion was controlled at 40 °C. Afterwards, it was transferred to a drying oven at 60°C for 10 h. After complete drying, it was calcined in a muffle furnace at a heating rate of 15°C / min. During the heating process, the temperature was maintained at 300°C for 1 h and at 400°C for 1 hour. h, keep the temperature at 550°C for 4 h, and other operations are the same as in Example 1. The resulting photocatalytic hydrogen production was 1739 μmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com