A silicon-carbon double-acidity composite pellet used in converter slag modification and its preparation method

A technology of composite pellets and converter slag, which is applied in the field of steel slag comprehensive treatment, can solve the problems of affecting the stability of converter slag products, not realizing the potential value, limiting the scope of use of converter slag, etc., shortening the reduction time and smelting cycle, improving Effects of reaction kinetic conditions, reduction of power consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

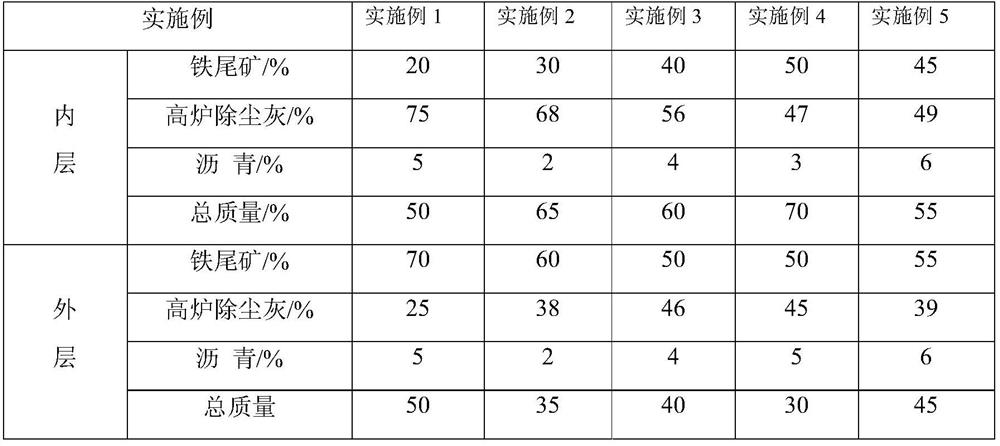

Embodiment 1

[0021] Silicon-carbon double-acidity composite pellets are prepared by the roller pressing process; the raw material composition of the inner layer is formed by mixing and pressing according to the ratio of 20% iron tailings, 75% blast furnace dust, and 5% asphalt, and the acidity coefficient MK=(SiO 2 +Al 2 o 3 ) / (CaO+MgO)=5. The outer layer material is formed by mixing and pressing according to the ratio of 70% iron tailings, 25% blast furnace dust, and 5% asphalt, and the acidity coefficient MK=(SiO 2 +Al 2 o 3 ) / (CaO+MgO)=20. Put the mixture of the inner and outer layers in the heating furnace and heat it to 350°C; 2 Under the pressure of 60mm, the elliptical silicon-carbon double-acidity composite pellets with a certain strength are made by using a pair of roller press ball machines.

Embodiment 2

[0023] Silicon-carbon double-acidity composite pellets are prepared by the roller pressing process; the raw material composition of the inner layer is formed by mixing and pressing according to the ratio of 30% iron tailings, 68% blast furnace dust, and 2% asphalt, and the acidity coefficient MK=(SiO 2 +Al 2 o 3 ) / (CaO+MgO)=7. The outer material is formed by mixing and pressing according to the ratio of 60% of iron tailings, 38% of blast furnace dust, and 2% of asphalt, and the acidity coefficient MK=(SiO 2 +Al 2 o 3 ) / (CaO+MgO)=15. Put the mixture of the inner and outer layers in the heating furnace and heat it to 500°C; 2 Under the pressure of 40mm, the elliptical silicon-carbon double-acidity composite pellets with a certain strength are made by using a pair of roller press ball machines.

Embodiment 3

[0025] Silicon-carbon double-acidity composite pellets are prepared by the roller pressing process; the raw material composition of the inner layer is formed by mixing and pressing according to the ratio of 40% iron tailings, 56% blast furnace dust, and 4% asphalt, and the acidity coefficient MK=(SiO 2 +Al 2 o 3 ) / (CaO+MgO)=8. The outer material is formed by mixing and pressing according to the ratio of 50% iron tailings, 46% blast furnace dust, and 4% asphalt, and the acidity coefficient MK=(SiO 2 +Al 2 o 3 ) / (CaO+MgO)=13. Put the mixture of the inner and outer layers in the heating furnace and heat it to 450°C; 2 Under the pressure of 30mm, the elliptical silicon-carbon double-acidity composite pellets with a certain strength are made by using a pair of roller press ball machines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com