Super duplex stainless steel casting riser cutting and welding repair method

A duplex stainless steel, riser cutting technology, applied in welding connection methods, welding equipment, welding accessories, etc., can solve the problems of easy cracking, coarse grains, high scrap rate and other problems in castings, and achieve high yield and low cost. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

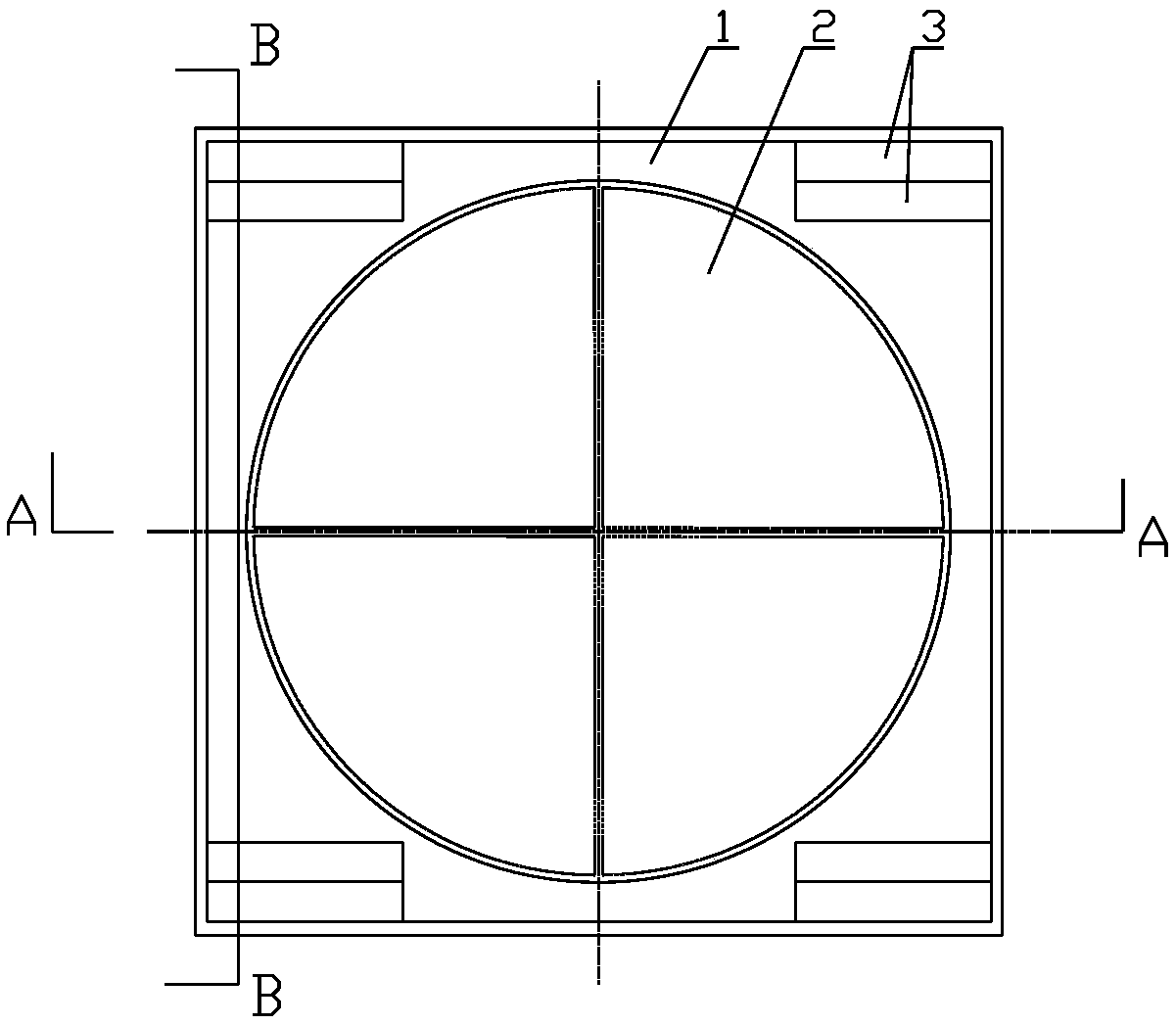

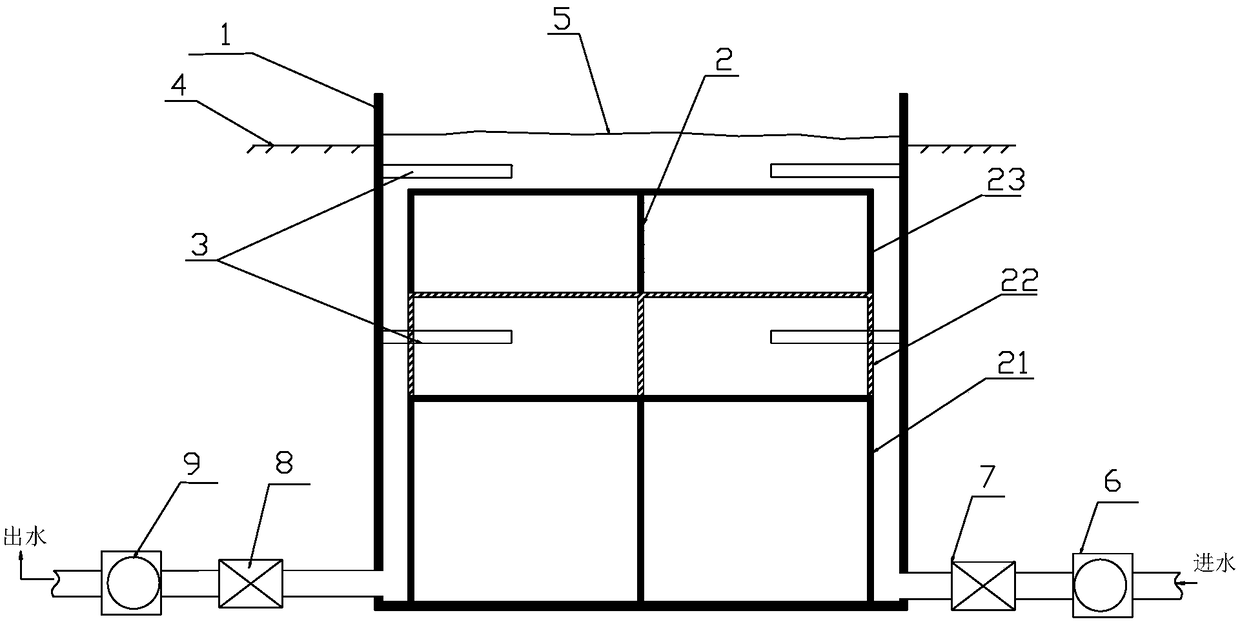

[0044] In this embodiment, the super duplex stainless steel high temperature and high pressure corrosion resistant pump (hereinafter referred to as the pump body 10), such as Figure 2a , Figure 2b As shown, it is a three-head screw pump body, and the specific parameters are as follows

[0045] (1) Material: super duplex stainless steel 6A

[0046] (2) The composition of the main chemical components is shown in the following table:

[0047] chemical composition

C

Si

mn

P

S

Cr

Ni

Mo

N

content(%)

≤0.03

≤1.0

≤1.5

≤0.04

≤0.02

24-26

6-8

4-5

0.1-0.3

[0048] (3) The material characteristics of the pump body 10:

[0049] The material used contains 24%-26% chromium and 0.1%-0.3% N, which is higher than the chromium and nitrogen content in ordinary duplex steel. It is a super duplex stainless steel, and the ferrite content in the matrix is required to reach 50%. The above has increased the difficulty ...

Embodiment 2

[0058] In this embodiment, the super duplex stainless steel high temperature and high pressure corrosion resistant valve (hereinafter referred to as the valve body 13), such as Figure 4a , 4b As shown, the specific parameters are as follows;

[0059] (1) Material: duplex stainless steel 5A;

[0060] (2) The chemical composition is as shown in the following table:

[0061] chemical composition

C

Si

mn

P

S

Cr

Ni

Mo

N

content(%)

≤0.03

≤1.0

≤1.5

0.04

≤0.02

24-26

6-8

4-5

0.1-0.3

[0062] (3) Structural characteristics of the valve body 13:

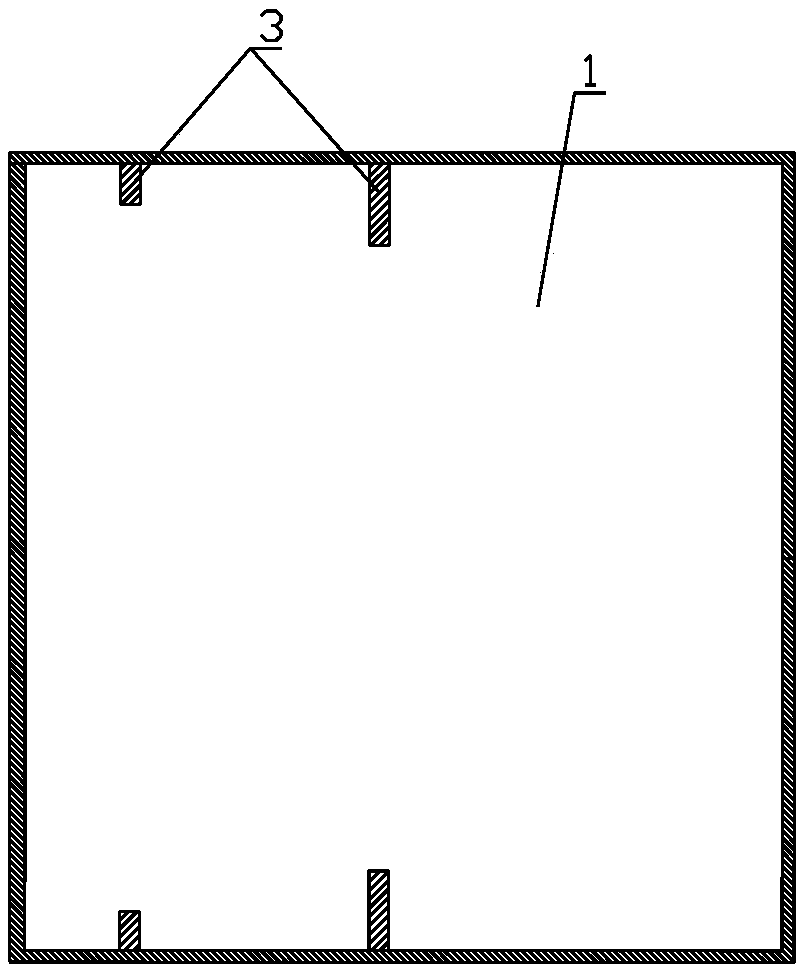

[0063] The valve body 13 is a 1500-pound valve body with relatively thick wall thickness. Therefore, the size of the riser 11 used in the design of the casting process is relatively large, and the heat generated during the riser cutting is relatively large, which is prone to cracks;

[0064] (4) Outline dimensions of valve body castings:

[0065] The maximum ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com