Magnetic separation type catalytic device for eliminating hydrogen peroxide and application thereof

A hydrogen peroxide, magnetic separation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, oxidized water/sewage treatment, etc., can solve problems such as increased operating costs and low catalytic activity , to improve the efficiency, the preparation process is simple, and the reaction rate is accelerated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

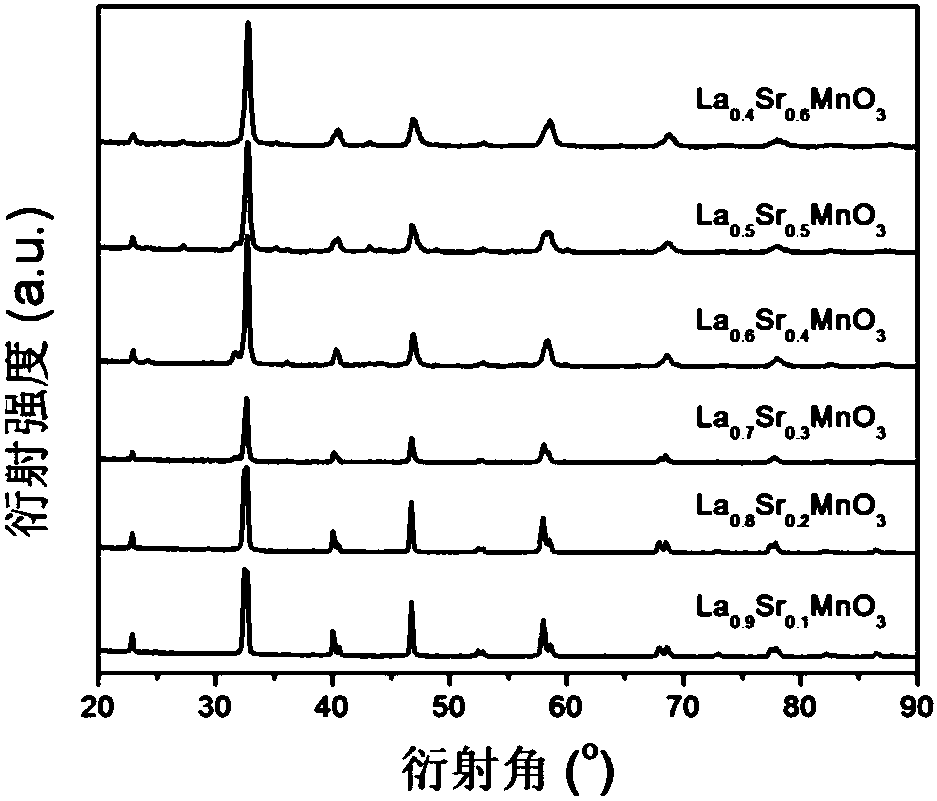

[0043] Embodiment 1 of the present invention discloses a magnetic catalytic material for eliminating hydrogen peroxide. The magnetic catalytic material is composed of perovskite oxides, and the structural formula of the perovskite oxides is ABO 3 ; A-position cations include one or more of rare earth metal ions or alkaline earth metal ions; B-position cations include one or more of transition metal ions.

[0044] In order to further optimize the technical solution, the perovskite oxide is La 1-x Sr x MnO 3 , x satisfies 01-x Sr x MnO 3 The specific surface area is less than 10mg L -1 .

[0045] In order to further optimize the technical solution, La 1-x Sr x MnO 3 In the preparation process, the sol-gel method is used to prepare the precursor, and then it is calcined in a muffle furnace at a high temperature of 900°C.

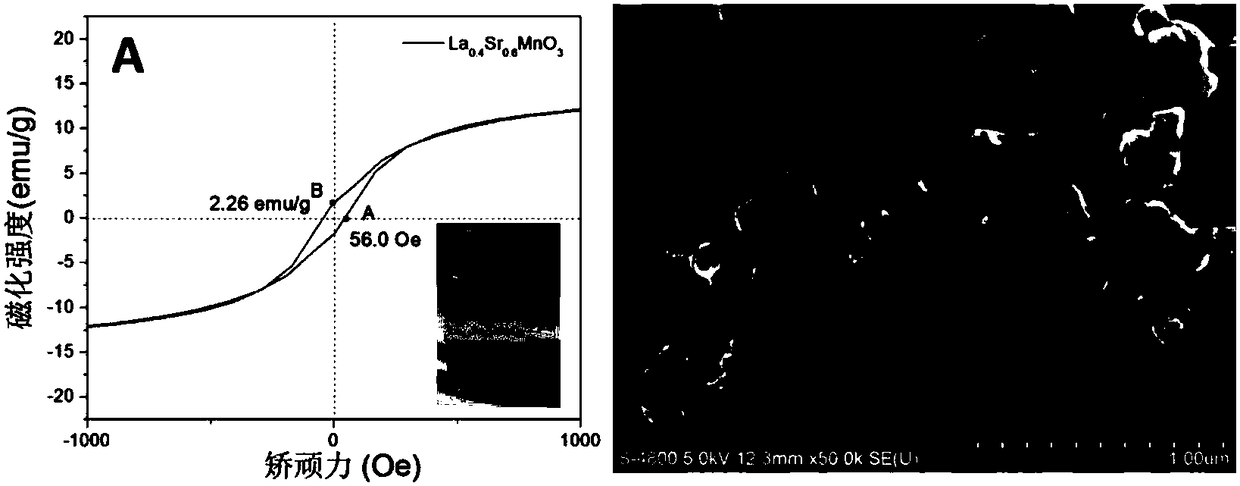

[0046] In order to further optimize the technical solution, a magnetic catalytic material for eliminating hydrogen peroxide includes La 0.4 Sr 0.6 M...

Embodiment 2

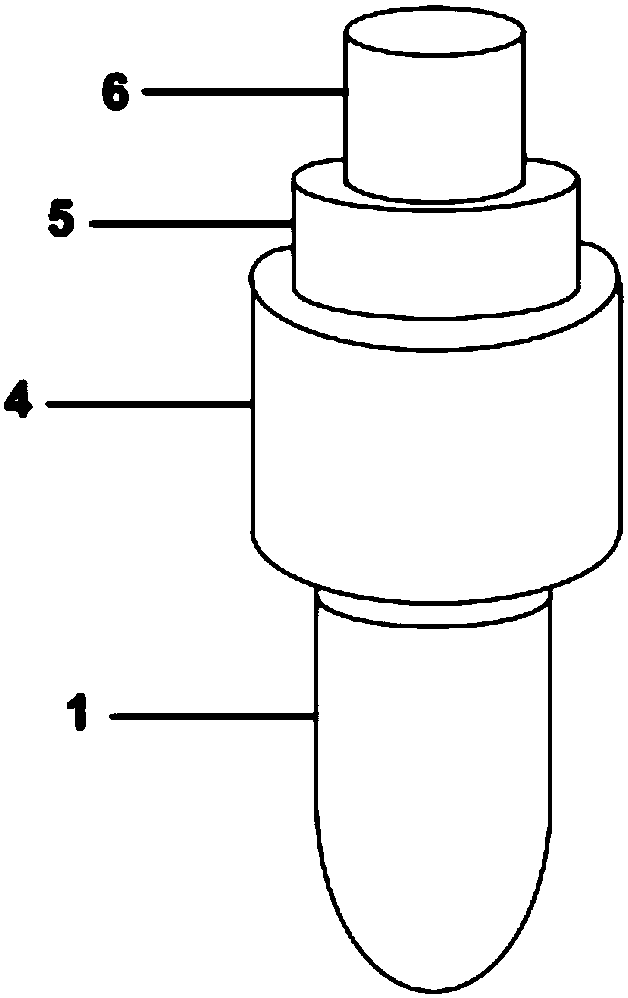

[0057] The embodiment of the invention also discloses a magnetic separation catalytic device for eliminating hydrogen peroxide, which includes a baffle, a decomposition tube and a tile-shaped magnet; a magnet is installed inside the baffle, and one side of the baffle is connected to the side of the decomposition tube. Bottom: The interior of the decomposition tube is filled with a magnetic catalytic material for eliminating hydrogen peroxide, and the decomposition tube is covered with tile-shaped magnets.

[0058] In order to further optimize the technical solution, a cooling pipe is also included. The bottom end of the cooling pipe is a closed structure, the top of the cooling pipe is connected to the other side of the baffle, and cooling water is installed in the cooling pipe.

[0059] In order to further optimize the technical solution, it also includes a pipe plug and a filter tube, the pipe plug is mated with the top of the decomposition tube, and the filter tube is passed...

Embodiment 3

[0062] The embodiment of the present invention also discloses a method for assembling a magnetic separation catalytic device for eliminating hydrogen peroxide, which specifically includes the following steps:

[0063] (1) Granulation of the magnetic catalytic material: the magnetic catalytic material in Example 1 is placed in a tableting mold, pressed under 15-25M unidirectional pressure for 2min into a sheet, and then the sheet is placed on a 30-60 mesh screen Medium grinding and granulation, collecting the particles left in the sieve, and pressing them into particles with a particle size larger than 30-60 mesh;

[0064] (2) Assembling the magnetic separation catalytic device: first fill the inside of the cooling tube with cooling water, then connect the top of the cooling tube to one side of the baffle with a magnet installed inside, and then connect the bottom of the decomposition tube to the other side of the baffle Connect, and finally bond the tile-shaped magnet to the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com