Bismuth vanadate-graphene composite photocatalyst, and preparation and application thereof

A graphene composite, photocatalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the complex reaction equipment, long preparation period and production cost. It can achieve high photocatalytic activity, short preparation cycle and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

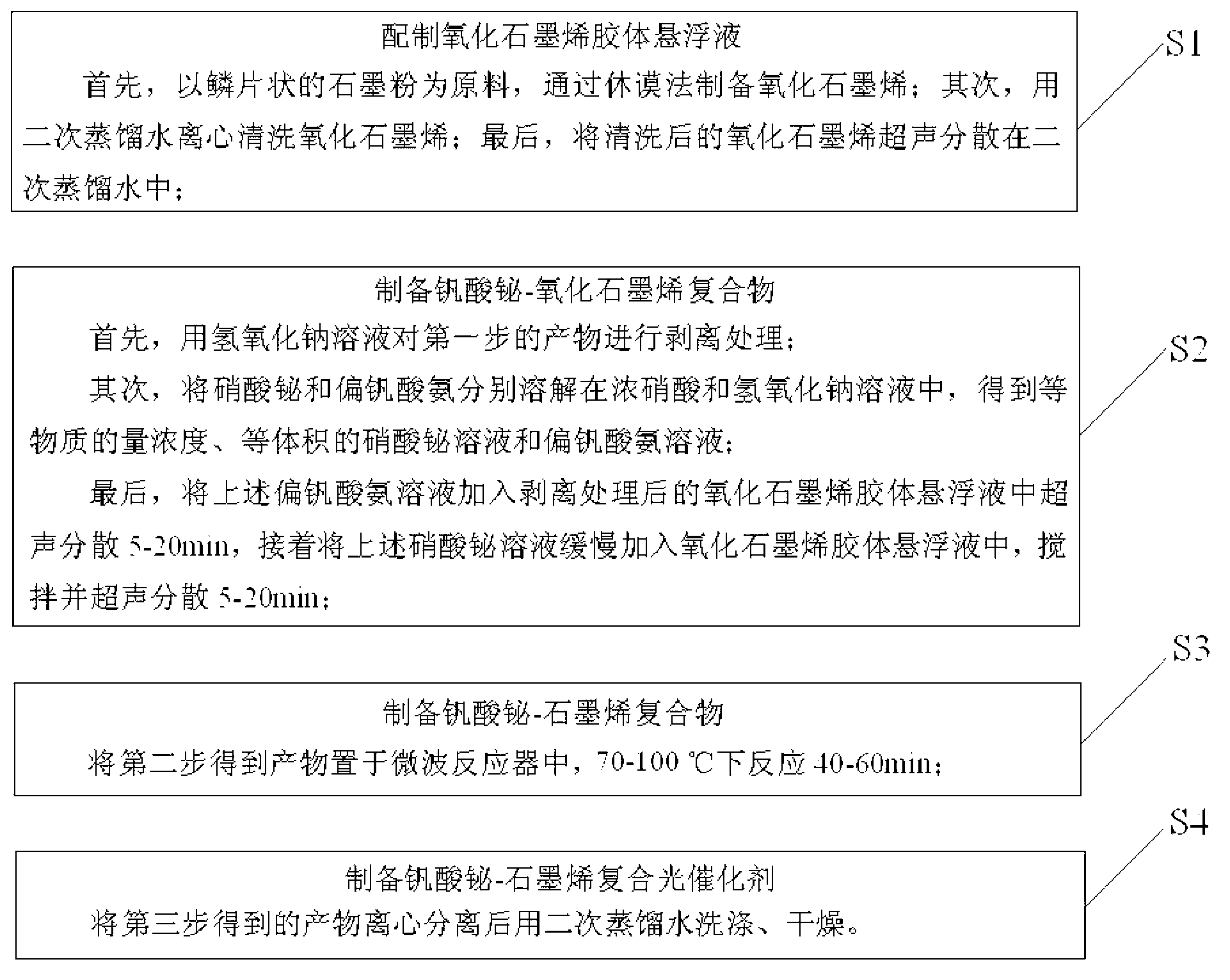

[0053] preparation:

[0054] The first step: preparation of graphene oxide colloidal suspension:

[0055] Firstly, graphene oxide was prepared by the Hume method using flake graphite powder as raw material; secondly, graphene oxide was centrifugally cleaned with double distilled water; finally, the cleaned graphene oxide was ultrasonically dispersed in double distilled water, and ultrasonic time 20-40min, the graphene oxide solution concentration is 2.9g / L;

[0056] The second step: preparation of bismuth vanadate-graphene oxide composite:

[0057] First, the product of the first step is stripped with sodium hydroxide solution;

[0058] Secondly, bismuth nitrate and ammonium metavanadate are dissolved in concentrated nitric acid and sodium hydroxide solution respectively to obtain bismuth nitrate solution and ammonium metavanadate solution of equal substance molar concentration and equal volume;

[0059] Finally, add the above-mentioned ammonium metavanadate solution into t...

Embodiment 2

[0067] preparation:

[0068] The first step: preparation of graphene oxide colloidal suspension:

[0069] Firstly, graphene oxide was prepared by the Hume method using flake graphite powder as raw material; secondly, graphene oxide was centrifugally cleaned with double distilled water; finally, the cleaned graphene oxide was ultrasonically dispersed in double distilled water, and ultrasonic time 20-40min, the graphene oxide solution concentration is 2.5g / L;

[0070] The second step: preparation of bismuth vanadate-graphene oxide composite:

[0071] First, the product of the first step is stripped with sodium hydroxide solution;

[0072] Secondly, bismuth nitrate and ammonium metavanadate are dissolved in concentrated nitric acid and sodium hydroxide solution respectively to obtain bismuth nitrate solution and ammonium metavanadate solution of equal substance molar concentration and equal volume;

[0073] Finally, add the above-mentioned ammonium metavanadate solution into t...

Embodiment 3

[0079] preparation:

[0080] The first step: preparation of graphene oxide colloidal suspension:

[0081] Firstly, graphene oxide was prepared by the Hume method using flake graphite powder as raw material; secondly, graphene oxide was centrifugally cleaned with double distilled water; finally, the cleaned graphene oxide was ultrasonically dispersed in double distilled water, and ultrasonic time 20-40min, the graphene oxide solution concentration is 3.2g / L;

[0082] The second step: preparation of bismuth vanadate-graphene oxide composite:

[0083] First, the product of the first step is stripped with sodium hydroxide solution;

[0084] Secondly, bismuth nitrate and ammonium metavanadate are dissolved in concentrated nitric acid and sodium hydroxide solution respectively to obtain equal substance molar concentrations and equal volumes of bismuth nitrate solution and ammonium metavanadate solution;

[0085] Finally, add the above-mentioned ammonium metavanadate solution into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com