Reflective film protective layer with acid and alkali resistance for photovoltaic module and manufacturing method thereof

A technology of photovoltaic modules and manufacturing methods, which is applied in the field of solar power generation, can solve problems such as reducing the utilization rate of light energy of cells, reducing the life of reflective films, and corrosion of plated metals, so as to improve utilization rates, increase power generation, and prevent corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

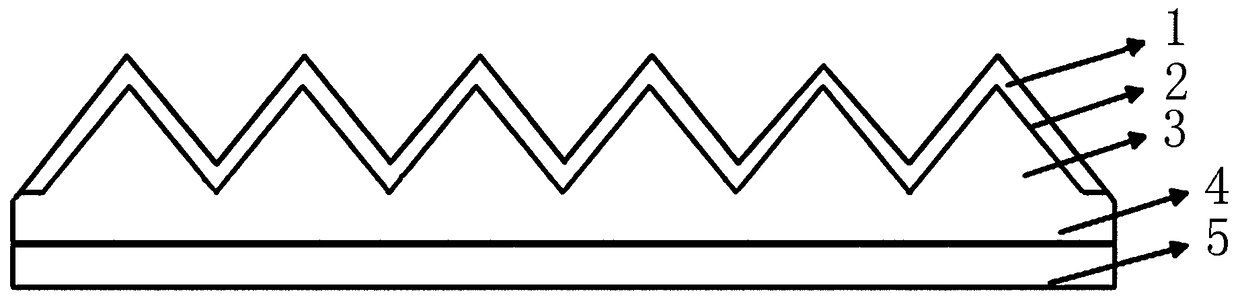

[0035] Preparation of reflective film protective layer for photovoltaic modules with acid and alkali resistance

[0036] The preparation method of the reflective film protective layer for photovoltaic modules with acid and alkali resistance is as follows:

[0037] 1. Precision coating process: use PET substrate as the base layer, and use laminating equipment to coat UV-curable glue on the PET substrate through a mold roller with microstructure. The UV curing glue is acrylate UV curing glue, the coating speed of UV curing glue is 25m / min, the temperature of UV curing glue is room temperature, and the molding pressure is 3kg / cm 2 , choose H-type electrodeless lamp as the UV curing light source, so as to form a prism structure on the PET substrate and form a microstructure layer;

[0038] 2. Aluminum plating: Vacuum coating is used to evaporate metal aluminum on the surface of PET after forming a prism structure. The evaporation method is metal wire evaporation. The aluminum raw...

Embodiment 2

[0045] Preparation of reflective film protective layer for photovoltaic modules with acid and alkali resistance

[0046] The preparation method of the reflective film protective layer for photovoltaic modules with acid and alkali resistance is as follows:

[0047] 1. Precision coating process: Use laminating equipment to coat the PET substrate as the base layer, and use laminating equipment to coat the UV-curable glue on the PET substrate through a mold roller with a microstructure. The UV curing glue is acrylate UV curing glue, the coating speed of UV curing glue is 25m / min, the glue temperature is room temperature, and the molding pressure is 3kg / cm 2 , choose H-type electrodeless lamp as the UV curing light source, so as to form a prism structure on the PET substrate and form a microstructure layer;

[0048] 2. Aluminum plating: Vacuum coating is used to evaporate metal aluminum on the surface of PET after forming a prism structure. The evaporation method is metal wire eva...

Embodiment 3

[0055] Preparation of reflective film protective layer for photovoltaic modules with acid and alkali resistance

[0056] The preparation method of the reflective film protective layer for photovoltaic modules with acid and alkali resistance is as follows:

[0057] 1. Precision coating process: Use laminating equipment to coat the PET substrate as the base layer, and use laminating equipment to coat the UV-curable glue on the PET substrate through a mold roller with a microstructure. The UV curing glue is acrylate UV curing glue. The coating speed of UV curing glue is 25m / min, the glue temperature is room temperature, and the molding pressure is 3kg / cm2. Forming a prism structure, forming a microstructure layer;

[0058] 2. Aluminum plating: Vacuum coating is used to evaporate metal aluminum on the surface of PET after forming a prism structure. The evaporation method is metal wire evaporation. The aluminum raw material is high-purity aluminum strip with a purity of 99.99%. No...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com