Nitrogen and boron co-doped porous carbon material and preparation method and application thereof

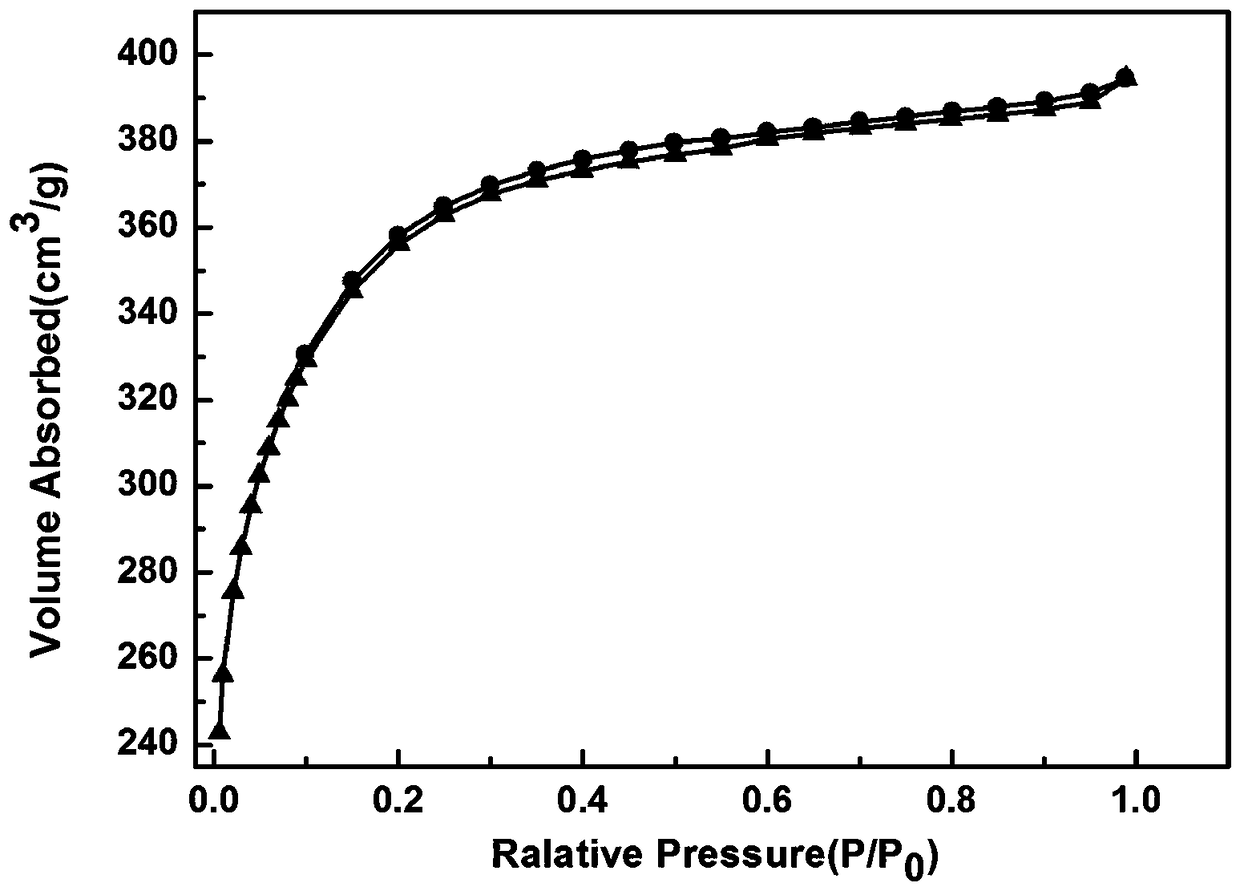

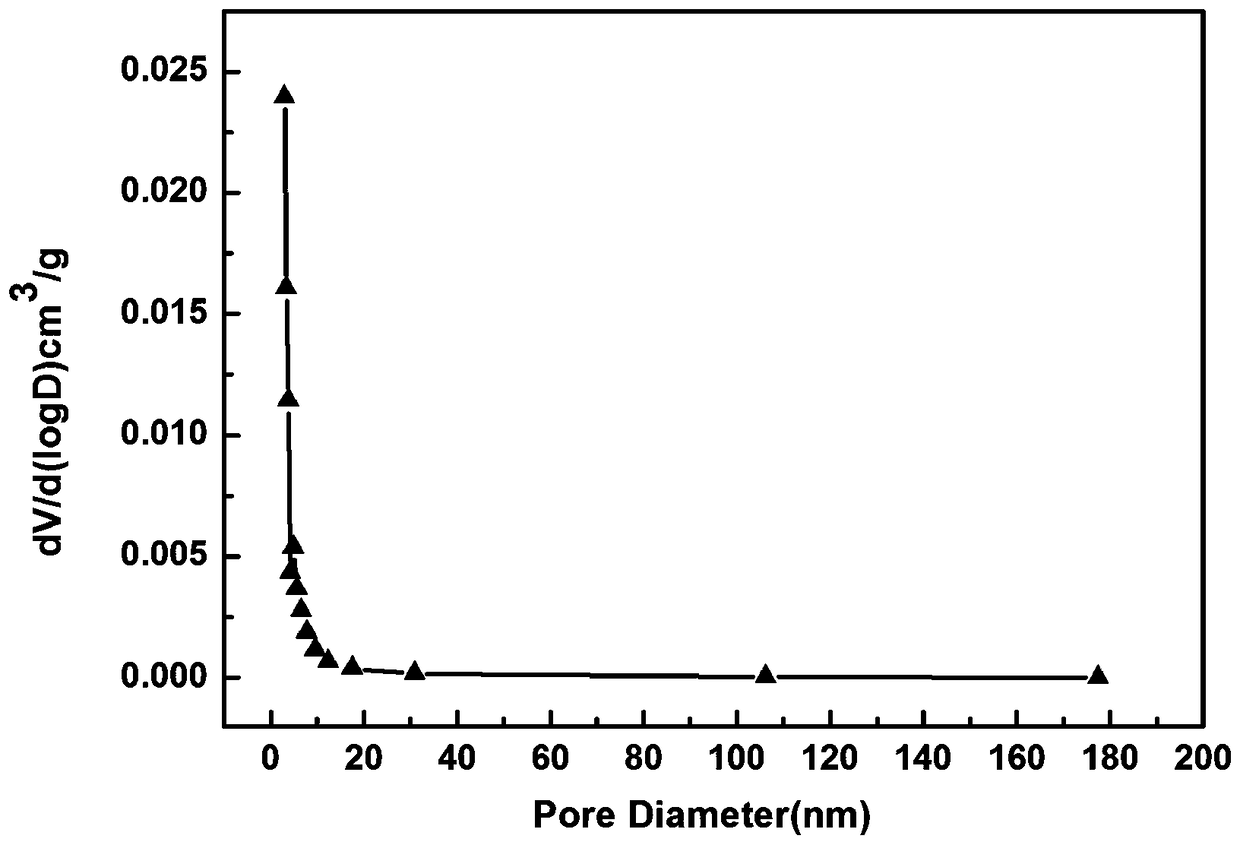

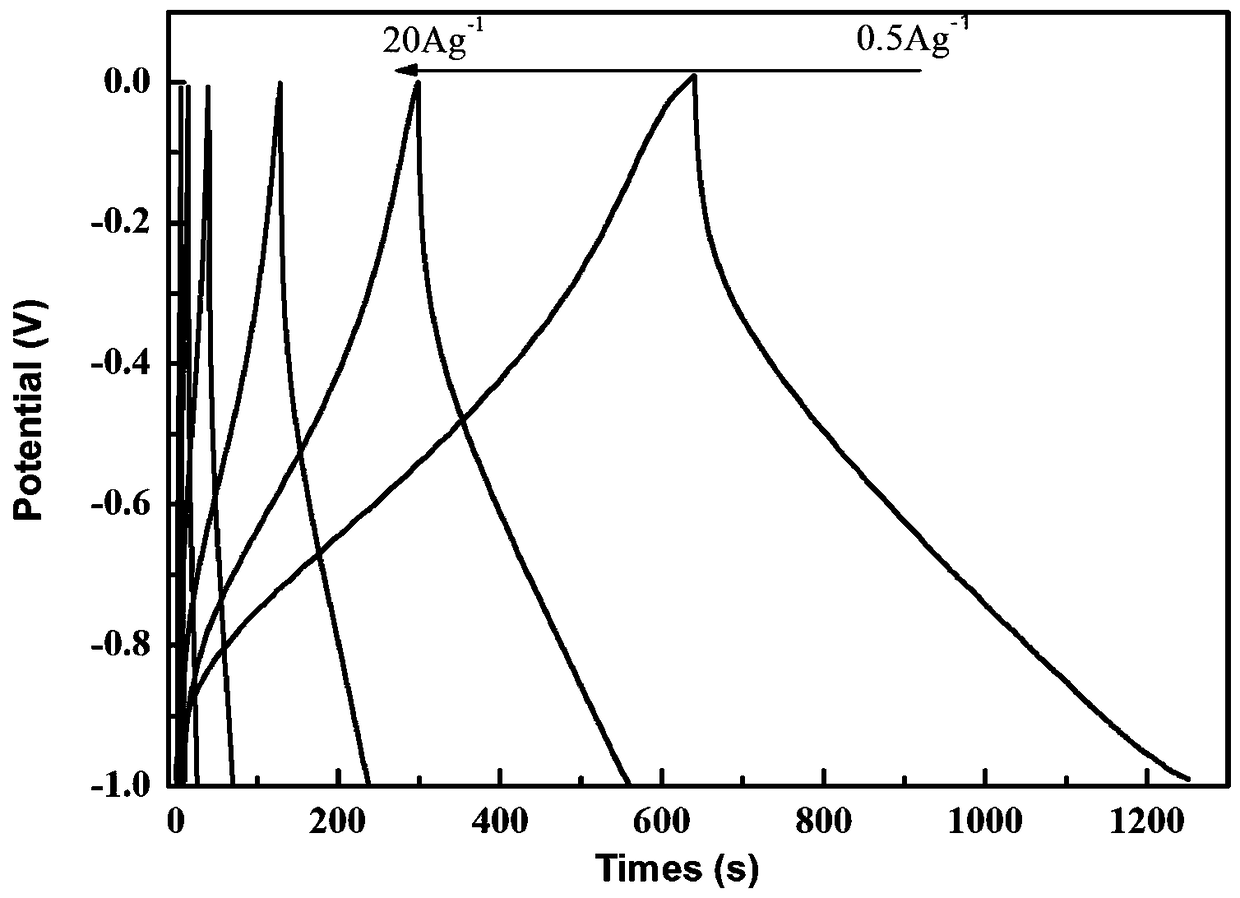

A porous carbon material and co-doping technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of cumbersome preparation process, high cost, and low capacitance storage of high-capacity electrode materials, and achieve favorable Electron transport, high specific capacitance, effect of good capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The preparation method of the nitrogen and boron co-doped porous carbon material is as follows:

[0037] Step 1) Preparation of nitrogen-containing boron precursor: 4 g glucose, 2 g melamine, and 0.5 g boric acid were added to deionized water and stirred to dissolve, and then put into a reactor to react at 180 ℃, then the product was filtered, Washing and drying to obtain a nitrogen-containing boron precursor;

[0038] Step 2) Activation of the nitrogen-containing boron precursor. The nitrogen-containing boron precursor and KOH are mixed and immersed in deionized water at a mass ratio of 1.0:2.0, stirred, placed in a blast drying oven, and then calcined at 600 ℃ under nitrogen protection 2 h, take out the calcined sample after cooling down and grind it to obtain an activated nitrogen-containing boron precursor material;

[0039] Step 3) Post-treatment of the nitrogen-containing boron precursor, washing the above product with deionized water to neutrality, filtering, drying, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com