Preparation method of high-carrying current Bi-2223 multi-core superconduction strip

A bi-2223, superconducting tape technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of high technical content and large difference in current-carrying performance. The effect of simplifying the tube loading process, improving connectivity and texture, and increasing the number of core wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] Step 1. The Bi-2223 powder prepared by the improved co-precipitation method is sintered at a high temperature to obtain Bi-2223 tube-packing precursor powder 1; the high-temperature sintering temperature is 820°C and the time is 28h;

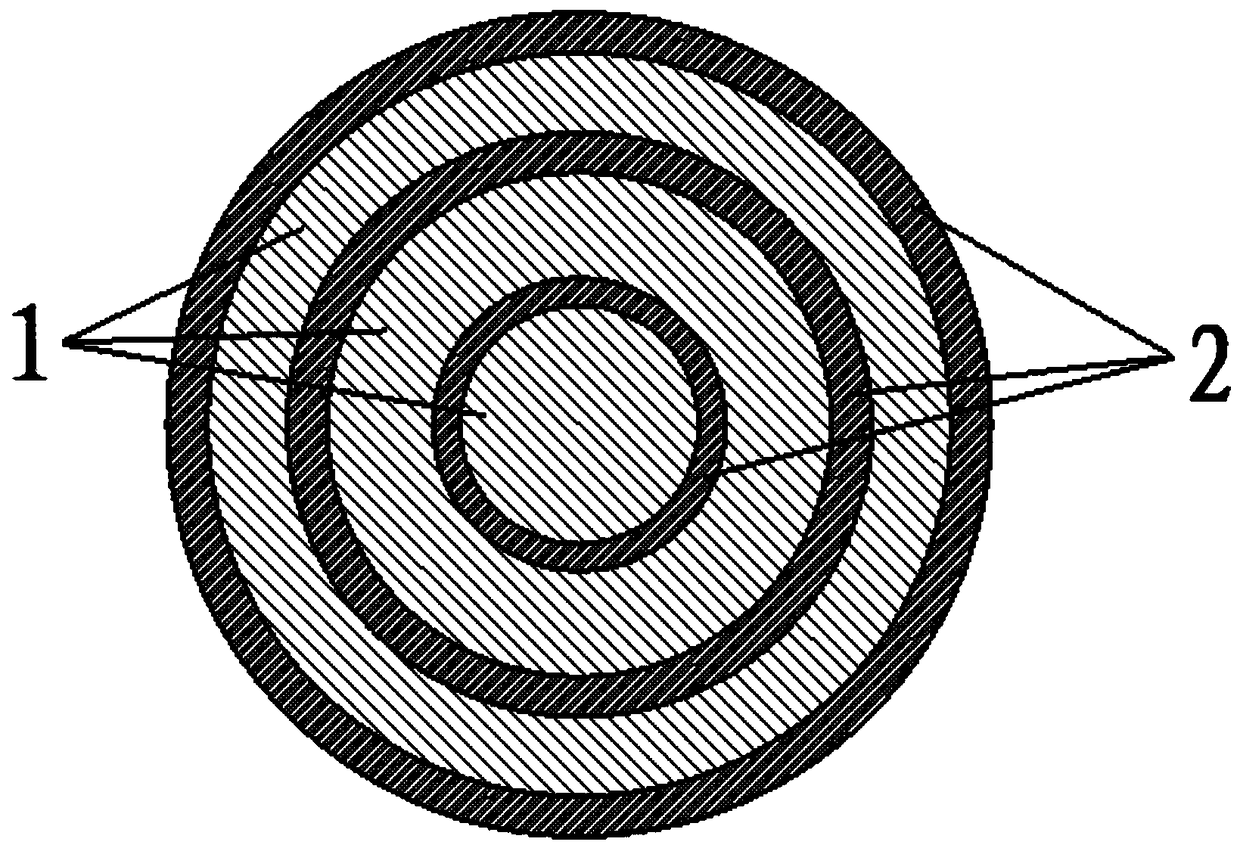

[0034] Step 2. In a glove box filled with high-purity oxygen atmosphere, use a vibrating table to vibrate the tube under the condition of a vibration frequency of 40 Hz, and load the Bi-2223 tube precursor powder 1 obtained in step 1 into the silver casing 2 In the gap, a first tube-filled composite body is obtained; the mass purity of the high-purity oxygen is 99.99%; the pressure in the glove box is higher than the atmospheric pressure of 400 Pa; the silver sleeve 2 is a silver tube whose center lines overlap Stacked, such as figure 1 As shown, the diameter of the outer layer of silver tube is 21mm and the wall thickness is 1mm, the diameter of the middle layer of silver tube is 14mm, an...

Embodiment 2

[0044] This embodiment includes the following steps:

[0045] Step 1. The Bi-2223 powder prepared by the improved co-precipitation method is sintered at a high temperature to obtain Bi-2223 tube-packing precursor powder 1. The high-temperature sintering temperature is 823°C and the time is 32h;

[0046] Step 2. In a glove box filled with high-purity oxygen atmosphere, use a vibrating table to vibrate the tube under the condition of a vibration frequency of 40 Hz, and load the Bi-2223 tube precursor powder 1 obtained in step 1 into the silver casing 2 In the gap, the first tube-filled composite body is obtained; the mass purity of the high-purity oxygen is 99.995%; the pressure in the glove box is higher than the atmospheric pressure of 400 Pa; the silver sleeve 2 is composed of three silver tubes whose center lines overlap Stacked, such as figure 1 As shown, the diameter of the outer silver tube is 31mm and the wall thickness is 1.5mm, the diameter of the middle silver tube is 21mm...

Embodiment 3

[0056] This embodiment includes the following steps:

[0057] Step 1. The Bi-2223 powder prepared by the improved co-precipitation method is sintered at a high temperature to obtain Bi-2223 tube-packing precursor powder 1. The high-temperature sintering temperature is 824°C and the time is 30h;

[0058] Step 2. In a glove box filled with high-purity oxygen atmosphere, use a vibrating table to vibrate the tube under the condition of a vibration frequency of 40 Hz, and load the Bi-2223 tube precursor powder 1 obtained in step 1 into the silver casing 2 In the gap, the first tube-filled composite body is obtained; the mass purity of the high-purity oxygen is 99.99%; the pressure in the glove box is 300 Pa higher than the atmospheric pressure; the silver sleeve 2 is a silver tube whose center lines overlap Stacked, such as figure 1 As shown, the diameter of the outer silver tube is 28mm and the wall thickness is 1.25mm, the diameter of the middle silver tube is 19.5mm, and the wall thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com