Zero-emission metal environment-friendly circulating oil removal method and device capable of recycling waste oil

A zero-emission, metal technology, applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as environmental hazards, large workshop pollution, workers' health effects, etc., to extend service life, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

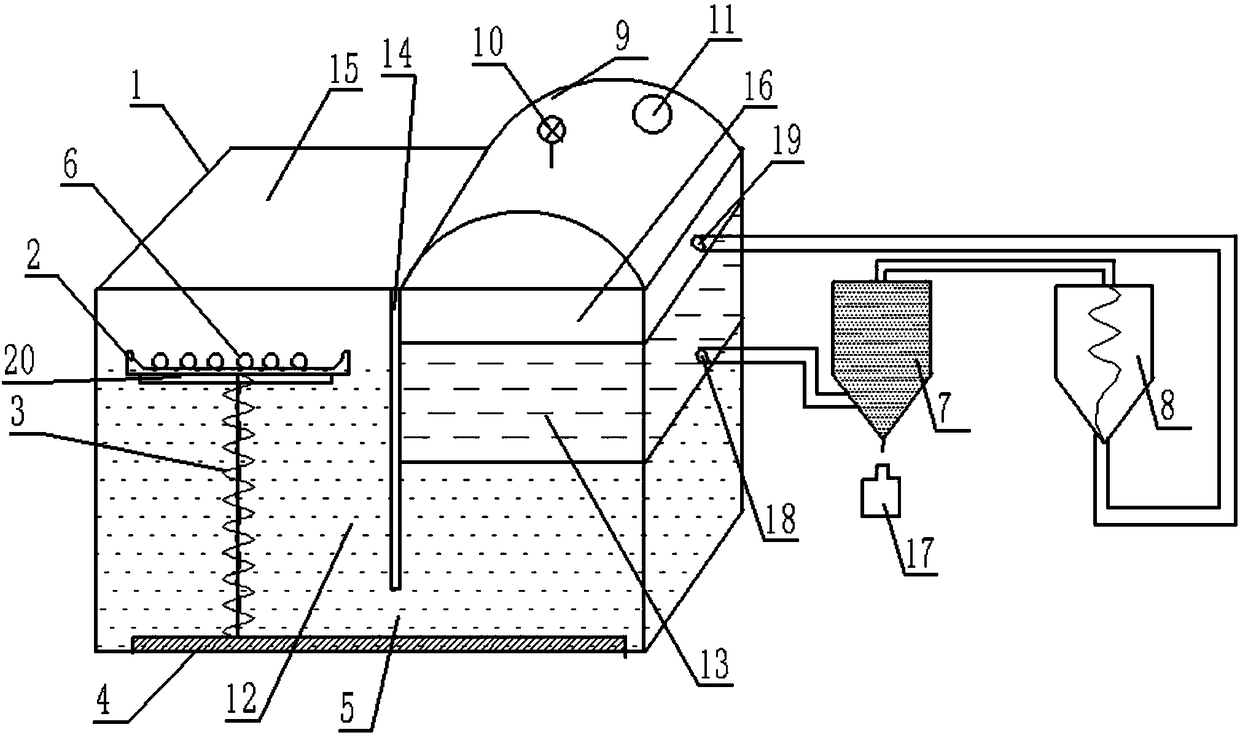

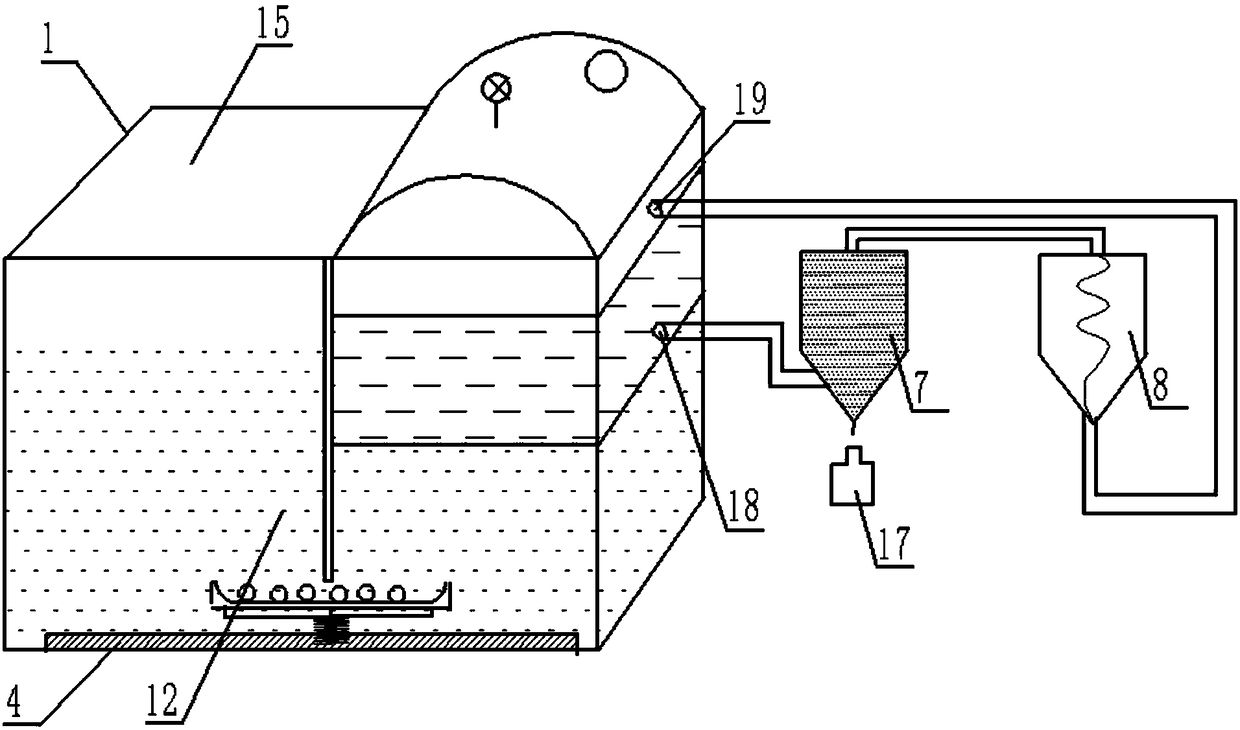

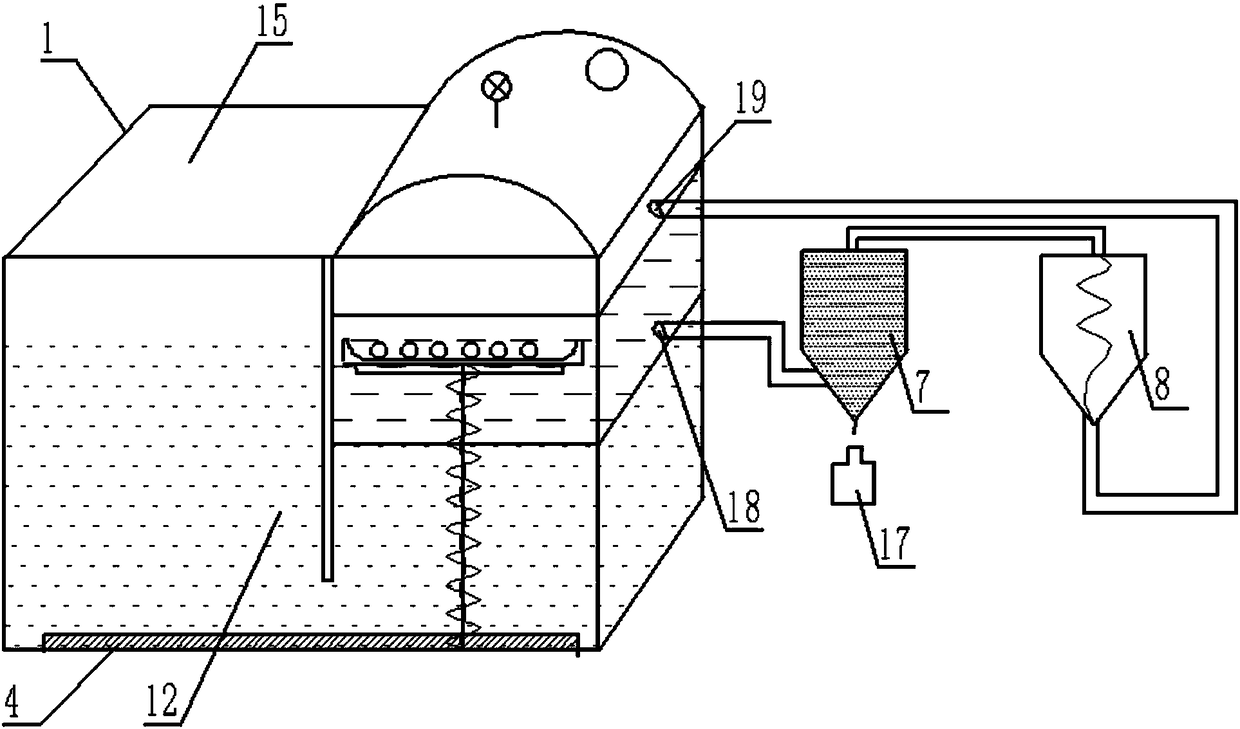

[0048] The present invention "a zero-discharge metal environmental protection cycle degreasing method and device that can recycle waste oil" provides a metal degreasing agent, and the components of the solvent 13 include: butane 45%, cyclohexane 15%, acetone 15%, butanone 25%; first add a certain height of water (sealing liquid) into the tank body 1, and then add the above-mentioned solvent 13 to the degreasing working area 16 of the device of the present invention. The workpiece 6 is a small mold, which is put into the workpiece pallet 2 of the device of the present invention, and is automatically degreased and regenerated by the device. After degreasing, hang it down for use.

Embodiment 2

[0050] The present invention "a zero-emission metal environmental protection cycle degreasing method and device that can recycle waste oil" provides a metal degreasing agent, the composition of the solvent 13 includes: gasoline 80%, kerosene 20%; first go to the tank 1, add a certain height of saline solution (sealing liquid), and then add the above-mentioned solvent 13 to the degreasing working area 16 of the device of the present invention. The workpiece 6 is an oiled screw, which is put into the workpiece pallet 2 of the device of the present invention, and is automatically degreased and regenerated by the device. After degreasing, hang it down for use.

Embodiment 3

[0052] The present invention "a zero-discharge metal environmental protection cycle degreasing method and device that can recycle waste oil" provides a metal degreasing agent. The composition of the solvent 13 includes: 100% solvent oil; A certain height of water (sealing fluid), and then the above-mentioned degreasing agent is added to the degreasing work area 16 of the device of the present invention. The tool is a hardware piece to be electroplated, which is placed on the workpiece tray 2 of the device of the present invention, and the device automatically degreases and regenerates. After degreasing, hang it down for use.

[0053] The invention can quickly remove grease and wax on the metal surface, whether it is vegetable oil, mineral oil or sintered oil formed at high temperature; whether it is grease or wax, whether it is light oil stain or heavy oil stain formed by long-term use (such as the inner liner of a liquefied petroleum tank) , can quickly remove them. The rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com