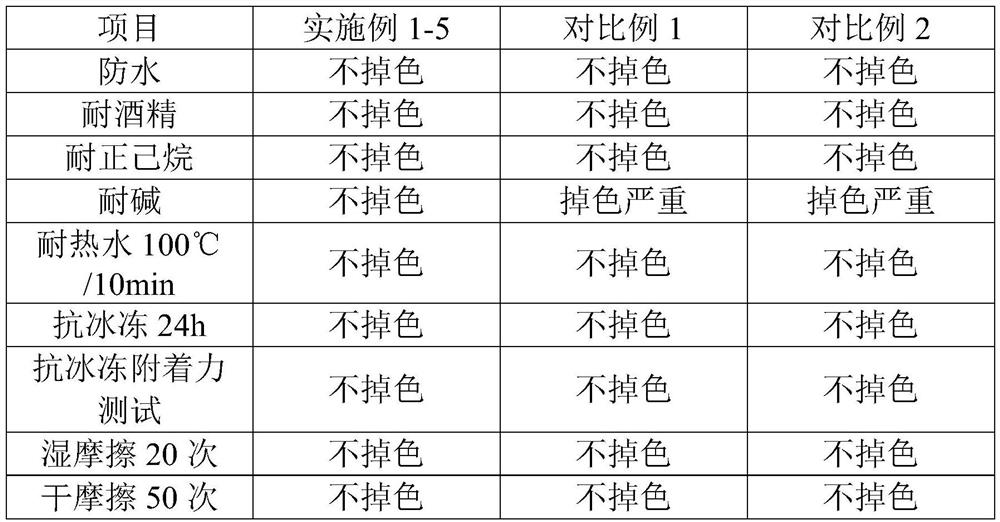

A kind of alkali-resistant water-based binder, its preparation method and the beer label water-based ink prepared by using it

A technology of alkali resistance and linking material, which is applied in the field of ink to achieve low production cost, good alkali resistance, and the effect of solving the effect of alkali washing and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An alkali-resistant water-based binder, made of the following raw materials in parts by weight: 15 parts of modified epoxy resin, 20 parts of acrylic mixed monomer, 10 parts of vinyl silane, 5 parts of mixed emulsifier, initiator A0. 5 parts, 0.1 part of defoamer A, 0.1 part of leveling agent, 0.5 part of neutralizer and 100 parts of water; wherein, the mixed emulsifier is made of PA emulsifier, epoxy emulsifier and reactive emulsifier with A mixture composed of a weight ratio of 0.5:0.8:1.

[0038] The PA emulsifier is made from the following raw materials in parts by weight: 40 parts of methacrylic acid, 30 parts of butyl acrylate, 10 parts of styrene and 0.4 parts of initiator B; wherein, the initiator B is benzyl peroxide Acyl;

[0039] The preparation method of the PA emulsifier is as follows: add methacrylic acid, butyl acrylate and styrene into the reaction kettle and stir, heat to 100°C, then add initiator B, react to a suitable viscosity state, 10min, cool dow...

Embodiment 2

[0049] An alkali-resistant water-based binder, made of the following raw materials in parts by weight: 18 parts of modified epoxy resin, 22 parts of acrylic mixed monomer, 15 parts of vinyl silane, 6 parts of mixed emulsifier, initiator A0. 6 parts, 0.2 part of defoamer A, 0.2 part of leveling agent, 0.8 part of neutralizer and 110 parts of water; Wherein, described mixed emulsifier is made of PA emulsifier, epoxy emulsifier and reactive emulsifier A mixture composed of a weight ratio of 0.8:0.9:1.

[0050] The PA emulsifier is prepared from the following raw materials in parts by weight: 45 parts of methacrylic acid, 35 parts of butyl acrylate, 12 parts of styrene and 0.5 parts of initiator B; wherein, the initiator B is azobisiso Nitrile;

[0051] The preparation method of the PA emulsifier is as follows: add methacrylic acid, butyl acrylate and styrene into the reaction kettle and stir, heat to 110°C, then add initiator B, react to a suitable viscosity state, 15min, and co...

Embodiment 3

[0061] An alkali-resistant water-based binder, made of the following raw materials in parts by weight: 20 parts of modified epoxy resin, 30 parts of acrylic mixed monomer, 15 parts of vinyl silane, 6 parts of mixed emulsifier, initiator A0. 6 parts, 0.3 part of defoamer A, 0.3 part of leveling agent, 1 part of neutralizing agent and 110 parts of water; Wherein, described mixed emulsifier is made of PA emulsifier, epoxy emulsifier and reactive emulsifier A mixture composed of a weight ratio of 1:1:1.

[0062] The PA emulsifier is made from the following raw materials in parts by weight: 50 parts of methacrylic acid, 40 parts of butyl acrylate, 10 parts of styrene and 0.5 part of initiator B; wherein, the initiator B is benzyl peroxide Acyl;

[0063] The preparation method of the PA emulsifier is as follows: add methacrylic acid, butyl acrylate and styrene into the reaction kettle and stir, heat to 120°C, then add initiator B, react to a suitable viscosity state, 25min, cool do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com