Processing method for interior wall latex paint having radon absorbing effect

A technology for interior latex paint and processing methods, applied in latex paint, biocide-containing paint, antifouling/underwater paint, etc., can solve problems such as increased damage intensity, and achieve increased emulsification, quality, and weather resistance Good, reduce decoration pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

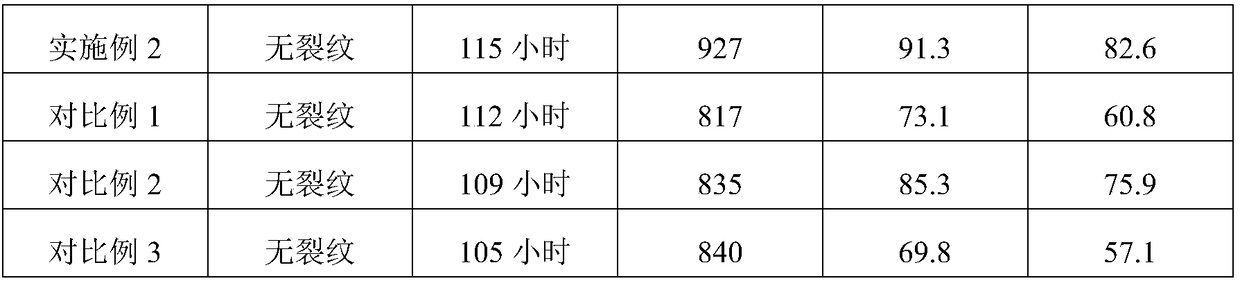

Examples

Embodiment 1

[0040] Present embodiment provides a kind of processing method of interior wall latex paint with radon absorbing effect, concrete process is as follows:

[0041] a. In parts by weight, take 23 parts of polyester resin, 5 parts of hydroxypropyl methacrylate, 40 parts of deionized water, 11 parts of silicon-acrylic emulsion, 4 parts of emulsifier, 31 parts of ethanol, and 1 part of dispersant. Stir evenly in a 150r / min agitator, transfer to the polymerization reactor, seal the reactor and add nitrogen gas accounting for 1 / 3 of the reactor volume, under the protection of nitrogen, drop 3 parts of initiator, slowly heat up, the heating rate The temperature is 5°C / min. After the temperature is raised to 55°C, the temperature is controlled to be constant, and the polymerization reaction is carried out. After the reaction is completed, it is cooled to room temperature, and the crude emulsion is prepared for use;

[0042] b. Transfer the above crude product emulsion to a closed mixer,...

Embodiment 2

[0053] Present embodiment provides a kind of processing method of interior wall latex paint with radon absorbing effect, concrete process is as follows:

[0054] a. In parts by weight, take 27 parts of polyester resin, 3 parts of hydroxypropyl methacrylate, 45 parts of deionized water, 13 parts of silicon-acrylic emulsion, 5 parts of emulsifier, 28 parts of ethanol, and 1 part of dispersant. Stir evenly in a 175r / min stirrer, transfer to the polymerization reactor, seal the reactor and add nitrogen gas accounting for 1 / 3 of the reactor volume, under the protection of nitrogen, add 3.5 parts of the initiator dropwise, slowly heat up, the heating rate The temperature is 5°C / min. After the temperature is raised to 55°C, the temperature is controlled to be constant, and the polymerization reaction is carried out. After the reaction is completed, it is cooled to room temperature, and the crude emulsion is prepared for use;

[0055] b. Transfer the above crude product emulsion to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com