Spray-free matte PC-ABS alloy material and preparation method thereof

A PC-ABS and alloy material technology, which is applied in the field of spray-free matte PC-ABS alloy material and its preparation, can solve the problems of spray-free characteristics, poor scratch resistance characteristics of matte characteristics, etc., and achieves excellent wear resistance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

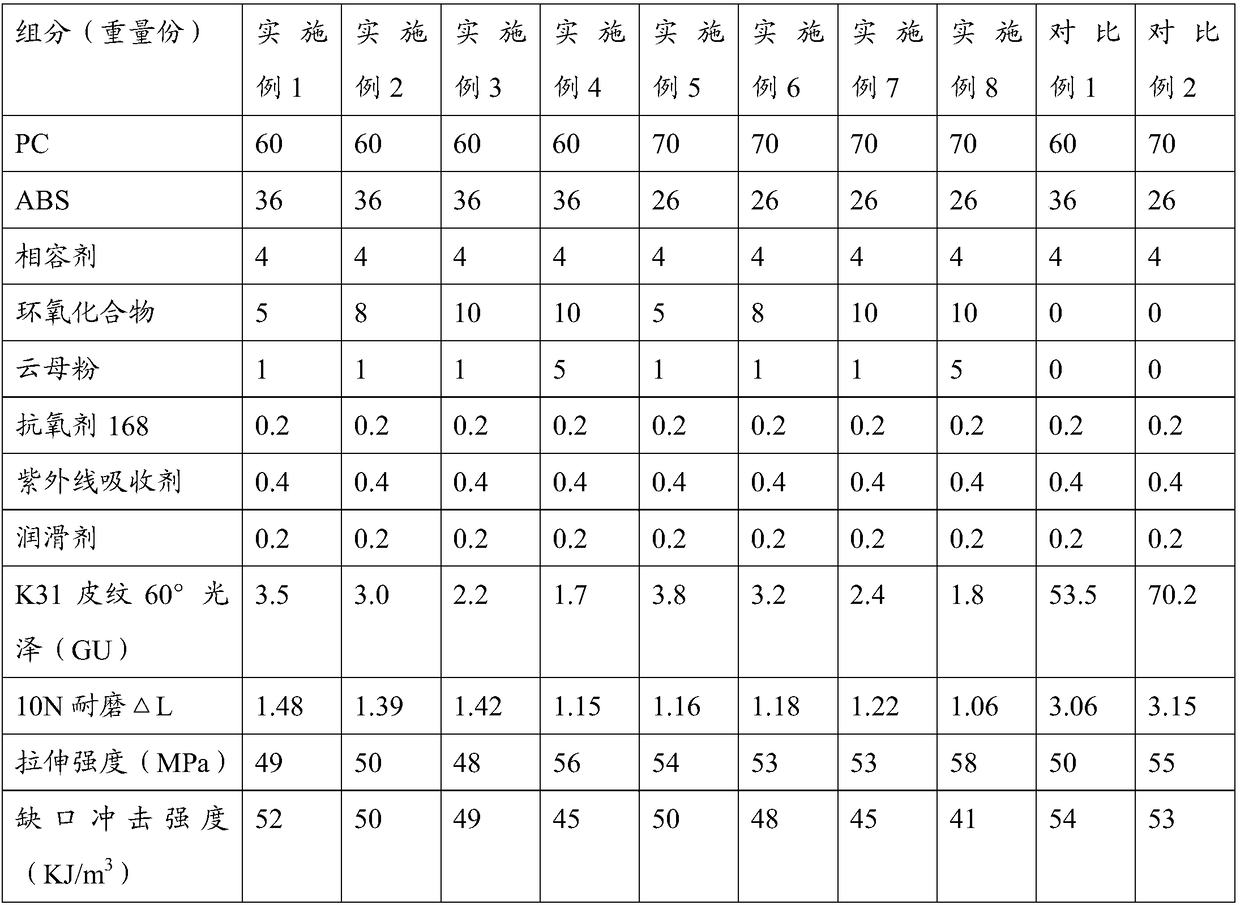

Examples

Embodiment 1

[0024] Weigh 60 parts of PC, 5 parts of epoxy compound, 36 parts of ABS, 2 parts of PMI, 1 part of mica powder, 0.4 parts of ultraviolet absorber UV-P, 4 parts of ABS-g-MAH compatibilizer, anti- 0.2 parts of oxygen agent 168, 0.2 parts of lubricant, 3 parts of calcium carbonate, 3 parts of carbon fiber, 1.5 parts of titanium oxide fiber, 1 part of glass fiber, 10 parts of polyethylene glycol, 4 parts of EBS, 15 parts of MBS, 5 parts of HDPE, flame retardant 1 part of magnesium hydroxide, 10 parts of PTT fiber, and 1.4 parts of EVA.

[0025] Put PC, epoxy compound, ABS, mica powder, ultraviolet absorber, ABS-g-MAH compatibilizer, antioxidant 168 and lubricant into a reaction kettle equipped with a stirrer and a thermometer, stir evenly, and heat up to 80°C , stirred for 5 min, and the stirring speed was 100 rpm.

[0026] Add the remaining raw materials, put them into the kneader, knead at 100°C for 20 minutes, melt and blend with a twin-screw extruder, extrude and granulate. ...

Embodiment 2

[0029] Weigh 60 parts of PC, 8 parts of epoxy compound, 36 parts of ABS, 2 parts of PMI, 1 part of mica powder, 0.4 part of ultraviolet absorber UV-327, 4 parts of LLDPE-g-MAH compatibilizer, anti- 0.2 parts of oxygen agent 168, 0.2 parts of lubricant, 10 parts of calcium carbonate, 4 parts of carbon fiber, 5.5 parts of titanium oxide fiber, 10 parts of glass fiber, 20 parts of polyethylene glycol, 8 parts of EBS, 20 parts of MBS, 10 parts of HDPE, flame retardant 5 parts of magnesium hydroxide, 30 parts of PTT fiber, and 1.8 parts of EVA.

[0030] Put PC, epoxy compound, ABS, mica powder, ultraviolet absorber, LLDPE-g-MAH compatibilizer, antioxidant 168 and lubricant into a reaction kettle equipped with a stirrer and a thermometer, stir evenly, and heat up to 100°C , stirred for 10 min, and the stirring speed was 250 rpm.

[0031] Add the remaining raw materials, put them into the kneader, knead at 120°C for 40 minutes, melt and blend them with a twin-screw extruder, extrude...

Embodiment 3

[0034] Weigh 60 parts of PC, 10 parts of epoxy compound, 36 parts of ABS, 2 parts of PMI, 1 part of mica powder, 0.4 part of ultraviolet absorber UV-327, 4 parts of SAN-g-MAH compatibilizer, anti 0.2 parts of oxygen agent 2245, 0.2 parts of lubricant, 6.5 parts of calcium carbonate, 3.5 parts of carbon fiber, 3.5 parts of titanium oxide fiber, 5 parts of glass fiber, 15 parts of polyethylene glycol, 6 parts of EBS, 18 parts of MBS, 8 parts of HDPE, flame retardant 3 parts of magnesium hydroxide, 20 parts of PTT fiber, and 1.6 parts of EVA.

[0035] Put PC, epoxy compound, ABS, mica powder, ultraviolet absorber, SAN-g-MAH compatibilizer, antioxidant 2245 and lubricant into a reaction kettle equipped with a stirrer and a thermometer, stir evenly, and heat up to 90°C , stirred for 8min, and the stirring speed was 170 rpm.

[0036] Add the remaining raw materials, put them into the kneader, knead at 110°C for 30 minutes, melt and blend with a twin-screw extruder, extrude and gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com