Thermoplastic elastic material for manufacturing extrusion tube and preparation method of thermoplastic elastic material

A thermoplastic elastic and extruded tube technology, applied in the polymer field, can solve the problems of poor surface elasticity and resilience, poor compression resistance, and easy deformation of the tube, and achieve good resilience, good electrical conductivity, and good surface elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

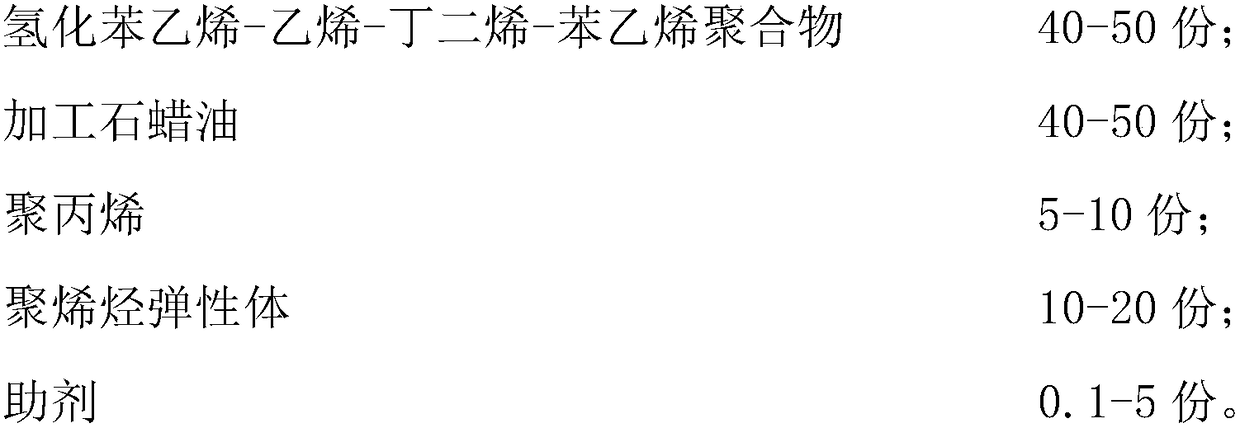

[0026] A thermoplastic elastic material for making extruded tubes, comprising the following raw materials in parts by weight,

[0027]

[0028] Further, the auxiliary agent includes an antiaging agent and an antistatic agent.

[0029] Further, the antistatic agent is polyol monostearate and nano-SiO 2 mixture.

[0030] Further, the antistatic agent is polyol monostearate and nano-SiO with a molar ratio of 1:1 2 mixture.

[0031] Further, the anti-aging additive is 2-hydroxy-4-n-octyloxybenzophenone, benzophenone and β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid Mixture of stearyl esters.

[0032] Further, the 2-hydroxy-4-n-octyloxybenzophenone, benzophenone, β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate The mass ratio is 1:1:1.

[0033] A method for preparing a thermoplastic elastic material for making an extruded tube, comprising the steps of,

[0034] (1) Mix the raw materials in proportion, and at room temperature, stir evenly to obtain the mix...

Embodiment 2

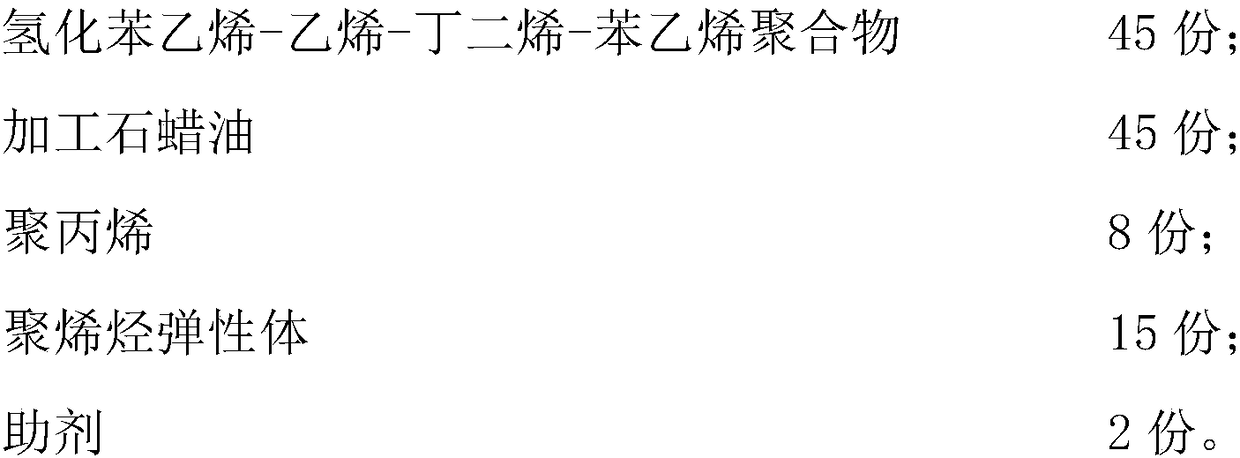

[0040] The difference between embodiment 2 and embodiment 1 is that

[0041] A thermoplastic elastic material for making extruded tubes, comprising the following raw materials in parts by weight,

[0042]

[0043] Further, the auxiliary agent includes an antiaging agent and an antistatic agent.

[0044] Further, the antistatic agent is polyol monostearate and nano-SiO 2 mixture.

[0045] Further, the antistatic agent is polyol monostearate and nano-SiO with a molar ratio of 1:5 2 mixture.

[0046] Further, the anti-aging additive is 2-hydroxy-4-n-octyloxybenzophenone, benzophenone and β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid Mixture of stearyl esters.

[0047] Further, the 2-hydroxy-4-n-octyloxybenzophenone, benzophenone, β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate The mass ratio is 1:3:3.

[0048] A method for preparing a thermoplastic elastic material for making an extruded tube, characterized in that: comprising the following steps,

[...

Embodiment 3

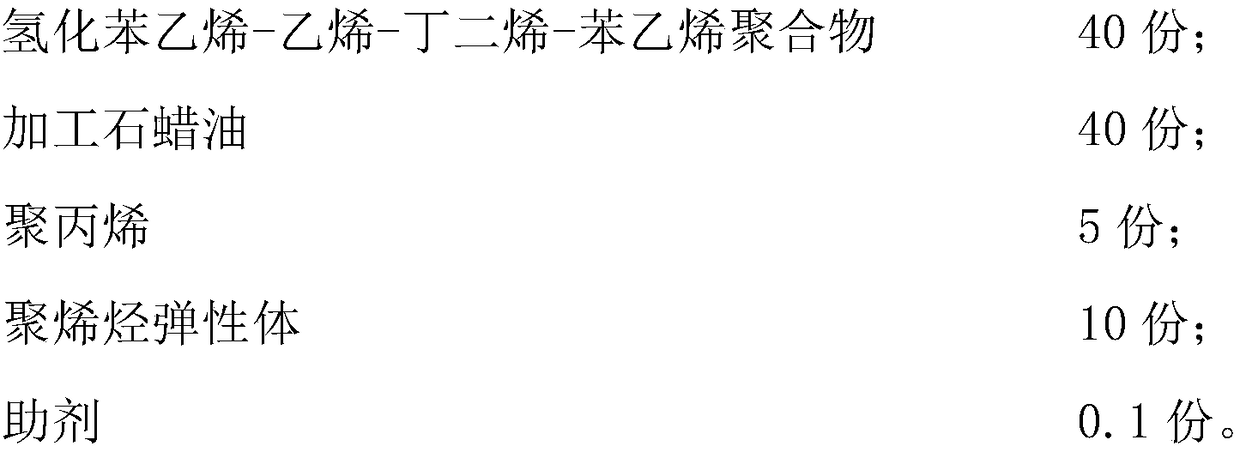

[0055] The difference between embodiment 3 and embodiment 1 is:

[0056] A thermoplastic elastic material for making extruded tubes, comprising the following raw materials in parts by weight,

[0057]

[0058] Further, the auxiliary agent includes an antiaging agent and an antistatic agent.

[0059] Further, the antistatic agent is polyol monostearate and nano-SiO 2 mixture.

[0060] Further, the antistatic agent is polyol monostearate and nano-SiO with a molar ratio of 1:3 2 mixture.

[0061] Further, the anti-aging additive is 2-hydroxy-4-n-octyloxybenzophenone, benzophenone and β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid Mixture of stearyl esters.

[0062] Further, the 2-hydroxy-4-n-octyloxybenzophenone, benzophenone, β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate The mass ratio is 1:2:2.

[0063] A method for preparing a thermoplastic elastic material for making an extruded tube, characterized in that: comprising the following steps,

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com