Preparation method of potassium sodium niobate-based ceramic

A potassium and sodium niobate-based ceramic technology is applied in the field of preparation of potassium and sodium niobate-based ceramics. Sintering performance, the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

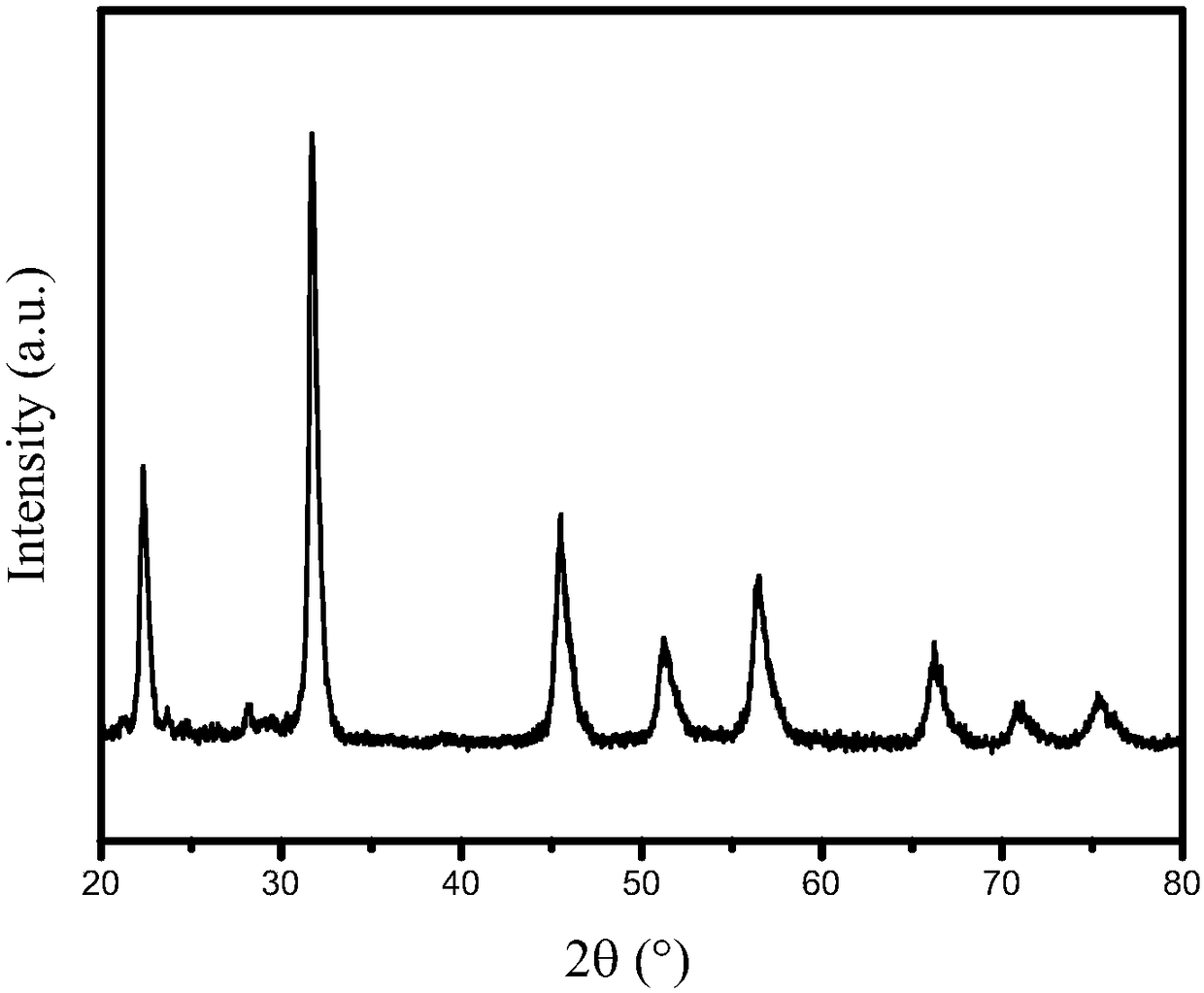

Image

Examples

preparation example Construction

[0029] A preparation method of potassium sodium niobate-based ceramics, comprising the following steps:

[0030] (1) Ingredients: according to chemical composition K x Na 1-x NbO 3 The stoichiometric ratio weighs the raw material K 2 CO 3 、Na 2 CO 3 and Nb 2 o 5 , mix well to obtain a mixture, where x=0.0-1.0;

[0031] (2) Primary ball milling: Add ball milling medium to the above mixture and place it in a nylon ball mill tank. The ball milling medium is alcohol and zirconia balls, and the mass ratio of zirconia balls, alcohol, and mixture is 2:0.5 : 1, then ball milling at a speed of 350-450r / min for 2 to 12 hours, then placing the mixture in an oven to dry at a temperature of 80 to 85°C, and then placing it in a mortar for grinding;

[0032] (3) Pre-burning: Put the ground mixture in a crucible, compact and cover it, put it in a muffle furnace, raise the temperature to 700-1000°C for constant temperature pre-burning for 1-6 hours, and naturally cool to room temperat...

Embodiment 1

[0038] A preparation method of potassium sodium niobate-based ceramics, comprising the following steps:

[0039] (1) Ingredients: according to chemical composition K x Na 1-x NbO 3 (x=0.0) stoichiometric ratio to weigh raw material K 2 CO 3 、Na 2 CO 3 、 Nb 2 o 5 mixing to obtain a mixture;

[0040] (2) One-time ball milling: add ball milling medium to the mixture, then put the mixture into a ball mill tank for ball milling for 2 hours, after the ball milling, put the mixture in an oven for drying at 80°C, and then The mixture is put into different mortars for grinding, wherein the ball milling medium is composed of alcohol and zirconia balls, and the mass ratio of the ball milling medium is 2:0. The mass ratio of 5:1 is added to the mixture to be ball milled;

[0041] (3) Pre-burning: Add the above-mentioned ground mixture into the crucible, compact and cover it, put it in a muffle furnace, raise the temperature to 700°C for constant temperature pre-burning for 2 ho...

Embodiment 2

[0047] A preparation method of potassium sodium niobate-based ceramics, comprising the following steps:

[0048] (1) Ingredients: according to chemical composition K x Na 1-x NbO 3 (x=0.5) stoichiometric ratio to weigh raw material K 2 CO 3 、Na 2 CO 3 、 Nb 2 o 5 mixing to obtain a mixture;

[0049] (2) One-time ball milling: add ball milling medium to the mixture, put the mixture into a ball mill tank and mill for 12 hours. After the ball milling, put the mixture in an oven to dry at 80°C, and The mixture is put into different mortars for grinding, wherein the ball milling medium is composed of alcohol and zirconia balls, and the mass ratio of the ball milling medium is 2:0. The mass ratio of 5:1 is added to the mixture to be ball milled;

[0050] (3) Pre-burning: Add the above-mentioned ground mixture into the crucible, compact and cover it, put it in a muffle furnace, raise the temperature to 850°C for constant temperature pre-burning for 4 hours, and then cool it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com