Lithium-aluminum-containing silicate glass capable of rapidly exchanging ions

A lithium-aluminosilicate, ion-exchange technology, used in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of reduced surface compressive stress, difficult to quickly obtain high ion-exchange layer depth, etc., and achieve high surface pressure. Stress, improve the resistance to external force damage, reduce the effect of stress relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

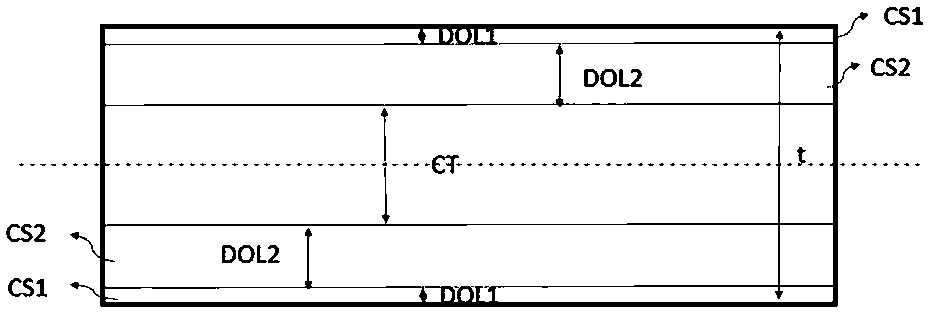

Image

Examples

Embodiment Construction

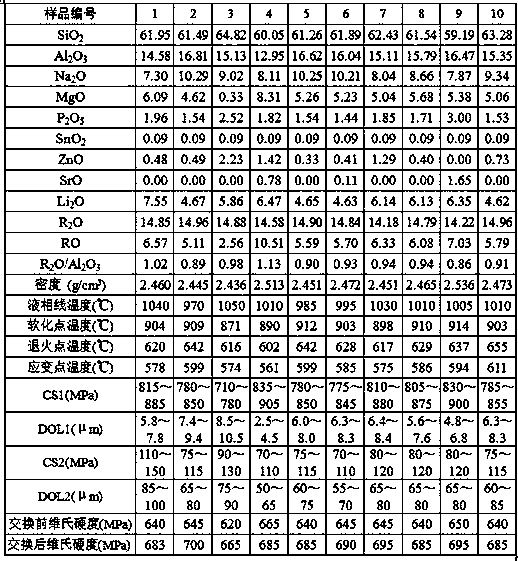

[0038] In order to further disclose rather than limit the present invention, the present invention will be further described in detail below in conjunction with examples.

[0039] 1) Test sample preparation

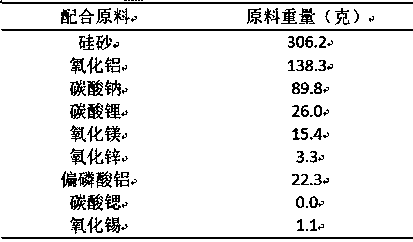

[0040] In the embodiment of the present invention, Table 2 is that No. 2 formula in Table 1 is prepared into a batch according to the purity and moisture content of each raw material; after weighing and mixing the raw materials shown in Table 1, to obtain a uniform batching; then the batch Transfer from the plastic bottle to about 800ml platinum crucible, put the platinum crucible into the silicon-molybdenum rod high-temperature furnace, gradually raise the temperature to 1650°C, hold the temperature for 3-8 hours, accelerate the discharge of glass bubbles and homogenize and eliminate the glass by stirring . After melting, pour the molten liquid into a heat-resistant stainless steel mold for molding, then take out the glass block and move it into a box-type annealing fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com