Polymer disk-shaped insulator for disk-shaped suspension insulator string element and preparation method

A technology of suspension insulators and polymers, applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve the problems of reduced creepage distance utilization, affect the safe operation of polymer insulators, and complex operating conditions, etc., to improve The ability to resist wind and sand, the best pollution flashover characteristics, and the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

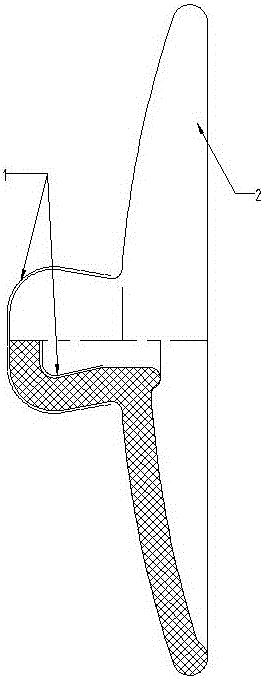

[0032] like figure 1 As shown, the polymer disc insulator for the disc suspension insulator string element proposed in the first embodiment of the present invention adopts an umbrella skirt structure.

[0033] like figure 1 As shown, the polymer disk insulator for the disk-shaped suspension insulator string element includes a shed 2, and the center of the shed 2 extends a U-shaped cavity extension 1; wherein the disk-shaped suspension Polymer disc insulation for insulator string elements is made of hydrophobic cycloaliphatic epoxy resin. Among them, such as figure 1 As shown, the shed 2 is a shed whose upper and lower surfaces are arc surfaces with a smooth transition. The umbrella extension of the umbrella skirt is 100mm-220mm, and the nominal disc diameter is 300mm-500mm. The umbrella extension refers to the radial distance between the outer edge of the composite insulator shed and the sheath.

Embodiment 2

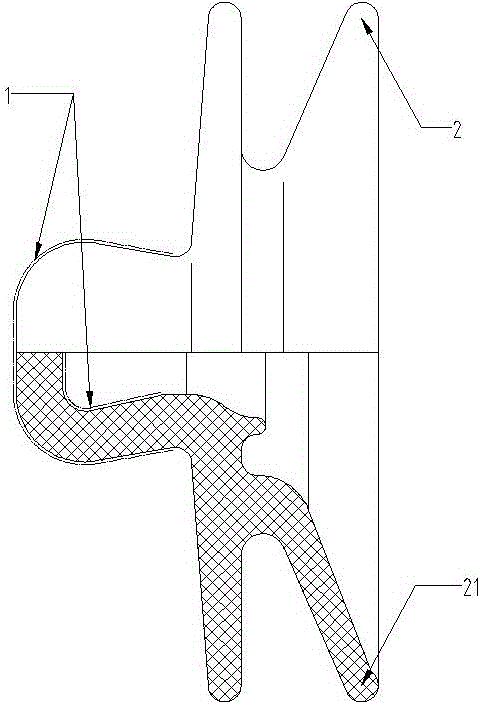

[0035] like figure 2 and image 3 As shown, the polymer disk-shaped insulator for the disk-shaped suspension insulator string element proposed by the second embodiment of the present invention adopts a multi-mushroom structure.

[0036] like figure 2 As shown, the polymer disk insulator for the disk-shaped suspension insulator string element includes a shed 2, and the center of the shed 2 extends a U-shaped cavity extension 1; wherein the disk-shaped suspension insulator The polymer disc insulation for string elements is made of hydrophobic cycloaliphatic epoxy resin. Wherein, the shed 2 is a shed with a double umbrella structure, including two large umbrella-shaped protrusions 21 parallel to each other. The diameters of the two large umbrella-shaped protrusions 21 may be equal or unequal.

[0037] like image 3 As shown, the polymer disk insulator for the disk-shaped suspension insulator string element includes a shed 2, and the center of the shed 2 extends a U-shaped ...

Embodiment 3

[0040] like Figure 4 As shown, the polymer disk-shaped insulator for the disk-shaped suspension insulator string element proposed by the third embodiment of the present invention adopts a bell-shaped structure with ribs. The polymer disc-shaped insulator for the disc-shaped suspension insulator string element includes a shed 2, and the center of the shed 2 extends a U-shaped cavity extension 1; wherein the disc-shaped suspension insulator string element is used The polymer disc insulation is made of hydrophobic cycloaliphatic epoxy resin. like Figure 4 As shown, the umbrella skirt 2 includes a bell-shaped body with side walls, and a plurality of prismatic protrusions 222 are provided on the inner wall. Wherein the uptilt angle of the shed 2 is 4°-16°, and the shed 2 protrudes from 80 mm to 200 mm, the nominal disc diameter is 150 mm to 500 mm, and the under-edge coefficient is 0.7 to 1.1.

[0041]Wherein, the bell shape refers to a U-shape with a side wall of a certain le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com