Layered two-dimensional material interlayer-confined metal or metal compound composite material as well as preparation method and application thereof

A metal compound, two-dimensional material technology, applied in chemical instruments and methods, catalyst activation/preparation, nanotechnology for materials and surface science, etc. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

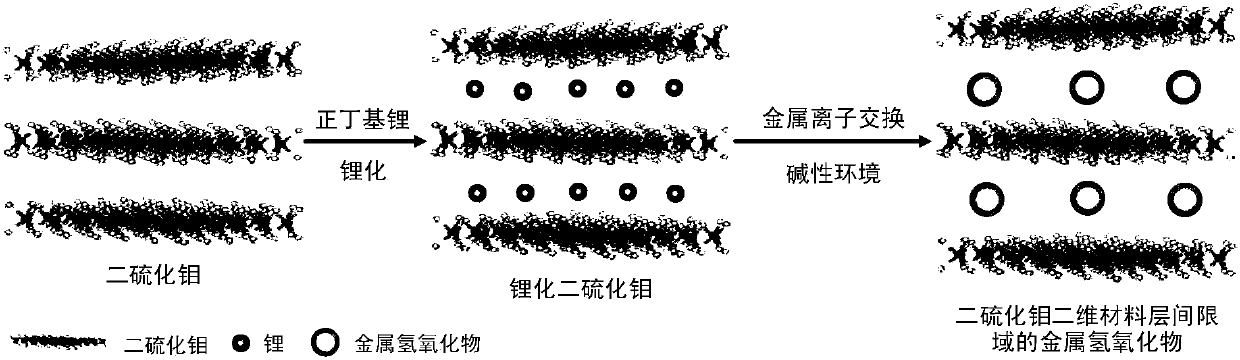

Embodiment 1

[0069]Two-dimensional molybdenum disulfide (1 g) was dispersed in n-butyllithium cyclohexane solution (2.0 M, 15 mL) for lithiation (48 h) under the protection of argon, and cyclohexane was used alternately to dilute the lithiated molybdenum sulfide product and High-speed (5000rpm) centrifugation (30min) three times respectively, and the bottom sediment was taken and dried naturally under the protection of argon. Followed by dry lithiated molybdenum disulfide: CoCl 2 ·6H 2 The ratio of O: THF is 100mg: 2.56g: 18mL, mix and seal in a hydrothermal reaction kettle, the pH of the reaction kettle system is 9.88, control the hydrothermal temperature to 80°C, and the holding time to 48 hours, and naturally cool to room temperature after the reaction , the obtained product is a composite material of two-dimensional molybdenum disulfide confined metal hydroxide (cobalt hydroxide), which is a highly efficient electrocatalyst. The schematic diagram of this two-step synthesis is shown i...

Embodiment 2

[0079] Two-dimensional molybdenum disulfide (1 g) was dispersed in n-butyllithium cyclohexane solution (2.0 M, 15 mL) for lithiation (72 h) under the protection of argon, and cyclohexane was used alternately to dilute the lithiated molybdenum sulfide product and High-speed (8000rpm) centrifugation (20min) three times respectively, and the bottom sediment was taken and dried naturally under the protection of argon. Followed by dry lithiated molybdenum disulfide: CoCl 2 ·6H 2 The ratio of O: tetrahydrofuran is 100mg: 0.256g: 18mL mixed and sealed in a hydrothermal reactor, the pH value of the reactor system is 8.5, the controlled hydrothermal temperature is 80°C, and the holding time is 24 hours. After the reaction is completed, it is naturally cooled to At room temperature, the obtained product is a composite material of two-dimensional molybdenum disulfide confined metal hydroxide (cobalt hydroxide). The schematic diagram of the two-step synthesis is as figure 1 shown.

[...

Embodiment 3

[0082] Two-dimensional molybdenum disulfide (0.5g) was dispersed in n-butyllithium cyclohexane solution (2.0M, 15mL) for lithiation (72h) under the protection of argon, and cyclohexane was used alternately to dilute the lithiated molybdenum sulfide product and Centrifuge at high speed (8000rpm) (20min) three times respectively, and take the bottom sediment and dry it naturally under the protection of argon. Followed by dry lithiated molybdenum disulfide:NiCl 2 ·6H 2 O: The ratio of tetrahydrofuran is 100mg: 0.274g: 18mL is mixed and sealed in a hydrothermal reactor, the pH value of the reactor system is 10, the controlled hydrothermal temperature is 80°C, and the holding time is 48 hours. After the reaction is completed, it is naturally cooled to At room temperature, the obtained product is a composite material of two-dimensional molybdenum disulfide confined metal hydroxide (nickel hydroxide), which is a highly efficient electrocatalyst. The schematic diagram of this two-st...

PUM

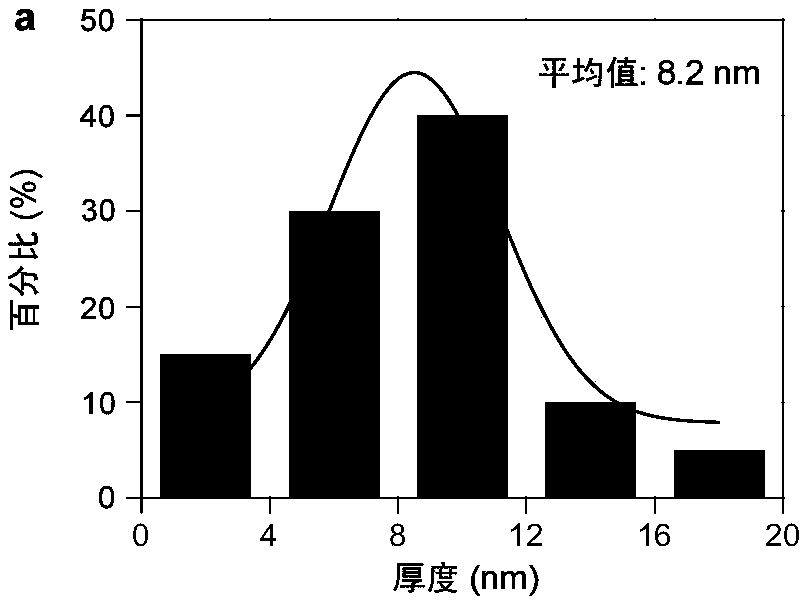

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Average horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com