Non-ferrous metal wire cutting paste and preparation method thereof

A non-ferrous metal, wire cutting technology, applied in the field of metal cutting, can solve the problem of not processing copper, and achieve the effect of reducing friction coefficient, good low temperature fluidity, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

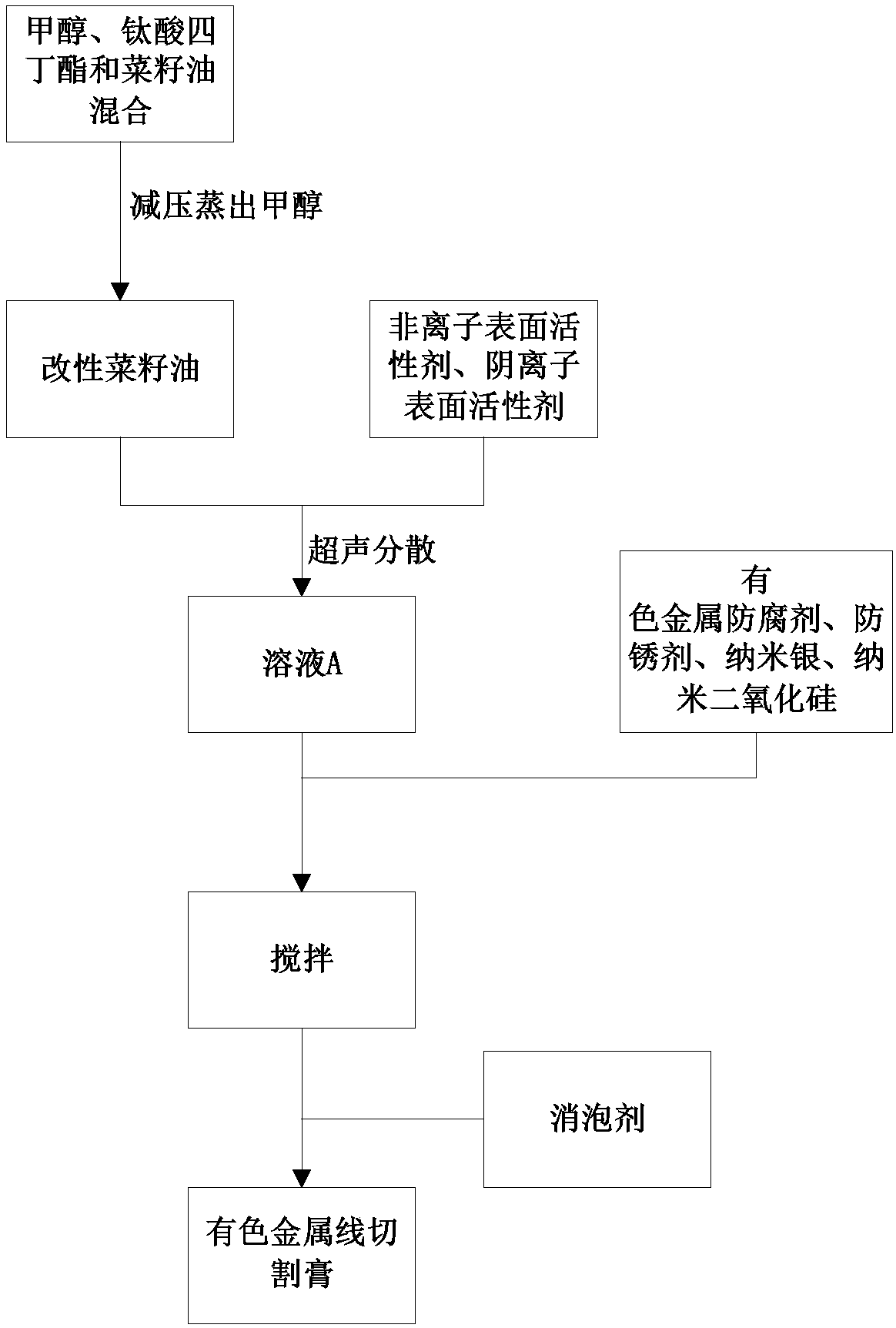

[0021] The preparation process of modified rapeseed oil is: mix methanol, tetrabutyl titanate and rapeseed oil, react at 15-55°C for 3-5 hours, after the reaction is completed, distill off the remaining methanol under reduced pressure to obtain modified Compared with the modified rapeseed oil, the modified rapeseed oil has greatly improved the oxidation stability, extreme pressure and anti-wear properties.

[0022] The non-ferrous metal preservative uses benzotriazole, which has a melting point of 98.5°C, a boiling point of 204°C, and a pH value of 5.0-6.0.

[0023] Alkanolamides are selected as non-ionic surfactants. The pH value of alkanolamides is 9.0-11.0, and the appearance is a light yellow clear liquid. It is stable in acid and alkali, has strong wetting and emulsifying power, and can improve foaming. Power, detergency, hard water resistance, can be used as detergent, wetting agent, emulsifier.

[0024] The anionic surfactant is sodium lauryl sulfate, and the density o...

Embodiment 1

[0034] Example 1: In parts by mass, 3.5 parts of alkanolamide and 3.5 parts of sodium lauryl sulfate were sequentially added to 65 parts of modified rapeseed oil, and ultrasonically dispersed at 58°C for 1.5 hours to obtain solution A; In terms of parts by mass, 4 parts of benzotriazole, 3 parts of sodium benzoate, 0.8 parts of nano-silver, and 1.0 parts of nano-silica were added to solution A in sequence, stirred at 56°C for 35 minutes, and then 4.5 parts by mass of Methyl silicone oil, mixed evenly to obtain non-ferrous metal wire cutting paste.

[0035] Dilute the non-ferrous metal wire-cutting paste prepared in Example 1 with distilled water according to a mass ratio of 1:55 to prepare a wire-cutting fluid, which was measured by GB-T 3142-1982 Lubricant Bearing Capacity Determination Method (four-ball method). The maximum non-seizing load value PB of the obtained wire cutting fluid was 92 kg, and the sintering load value PD was 110 kg.

Embodiment 2

[0037] In parts by mass, 2.5 parts of alkanolamide and 3.0 parts of sodium lauryl sulfate were sequentially added to 55 parts of modified rapeseed oil, and ultrasonically dispersed at 56° C. for 1.5 h to obtain solution A; in parts by mass, Add 3.5 parts of benzotriazole, 3.5 parts of sodium benzoate, 0.6 parts of nano-silver, and 0.8 parts of nano-silica to solution A in sequence, stir at 60°C for 35 minutes, and then add 2.5 parts by mass of methyl silicone oil, Mix evenly to obtain non-ferrous metal wire cutting paste.

[0038] Dilute the non-ferrous metal wire-cutting paste prepared in Example 2 with distilled water according to a mass ratio of 1:58, and prepare a wire-cutting fluid, which is measured by GB-T 3142-1982 lubricant bearing capacity test method (four-ball method). The maximum non-seizing load value PB of the obtained wire cutting fluid was 89 kg, and the sintering load value PD was 115 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com