Preparation method of core-shell type titanium dioxide coated silica

A technology of silicon dioxide and titanium dioxide, which is applied in chemical instruments and methods, dyeing low-molecular-weight organic compounds, fibrous fillers, etc., to achieve good application prospects and the effect of improving hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] It is 15% ammonium chloride solution 333Kg to add mass concentration in reactor earlier, and 1000Kg mass concentration is the water glass solution of 10%, add the ammoniacal liquor-ammonium chloride damping fluid 2Kg that pH value is 7.5 simultaneously, temperature is raised to React at 80°C for 3 hours under the condition of strong mechanical stirring to obtain 76Kg of silicon dioxide. Then add 12.5Kg titanyl sulfate and 6.7Kg sodium acetate, and add 0.37Kg sodium dodecylbenzenesulfonate at the same time, adjust the reaction temperature to 70°C, and after 2 hours of reaction, wash, filter, dry, calcinate, pulverize and other processes, Finally, a core-shell titanium dioxide-coated silica product is obtained.

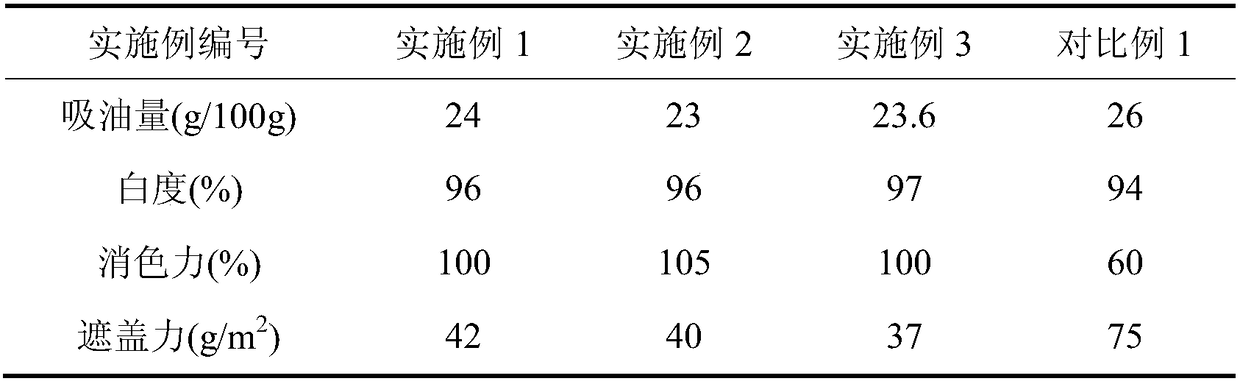

[0028] The test results of the obtained product performance and application performance are shown in Table 1.

Embodiment 2

[0030] It is 10% ammonium chloride solution 700Kg that adding mass concentration is 10% in reactor earlier, and 1300Kg mass concentration is the water glass solution of 12%, adds the ammoniacal liquor-ammonium chloride buffer solution 3Kg that pH value is 8.5 simultaneously, temperature is raised to React at 70°C for 4 hours under the condition of strong mechanical stirring to obtain 118Kg of silicon dioxide. Then add 47.2Kg titanyl sulfate and 28.8Kg sodium acetate, add fatty alcohol polyoxyethylene ether 1.88Kg at the same time, adjust the reaction temperature to 75°C, react for 3 hours and go through washing, filtering, drying, calcining, crushing and other processes to finally get Core-shell titanium dioxide coated silica products.

[0031] The test results of the obtained product performance and application performance are shown in Table 1.

Embodiment 3

[0033] It is 333Kg of ammonium chloride solution 333Kg that mass concentration is 12% in reactor earlier, and 900Kg mass concentration is 15% water glass solution, adds the ammoniacal liquor-ammonium chloride damping fluid 1.5Kg that pH value is 9.0 simultaneously, raises temperature To 90°C, react for 2h under the condition of strong mechanical stirring to obtain 103Kg of silicon dioxide. Then add 30.2Kg titanyl sulfate and 16.1Kg sodium acetate, and add 1.51Kg fatty acid glyceride at the same time, adjust the reaction temperature to 85°C, after 4 hours of reaction, wash, filter, dry, calcinate, crush and other processes, and finally get the core-shell type Titanium dioxide coated silica products.

[0034] The test results of the obtained product performance and application performance are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com