Method for producing a toughened glass article with a durable functional coating and a toughened glass article with a durable functional coating

A tempered glass, functional technology, applied in glass tempering, glass manufacturing equipment, chemical instruments and methods, etc., can solve problems such as unusable coated glass and uncontrollable warping of glass plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 5

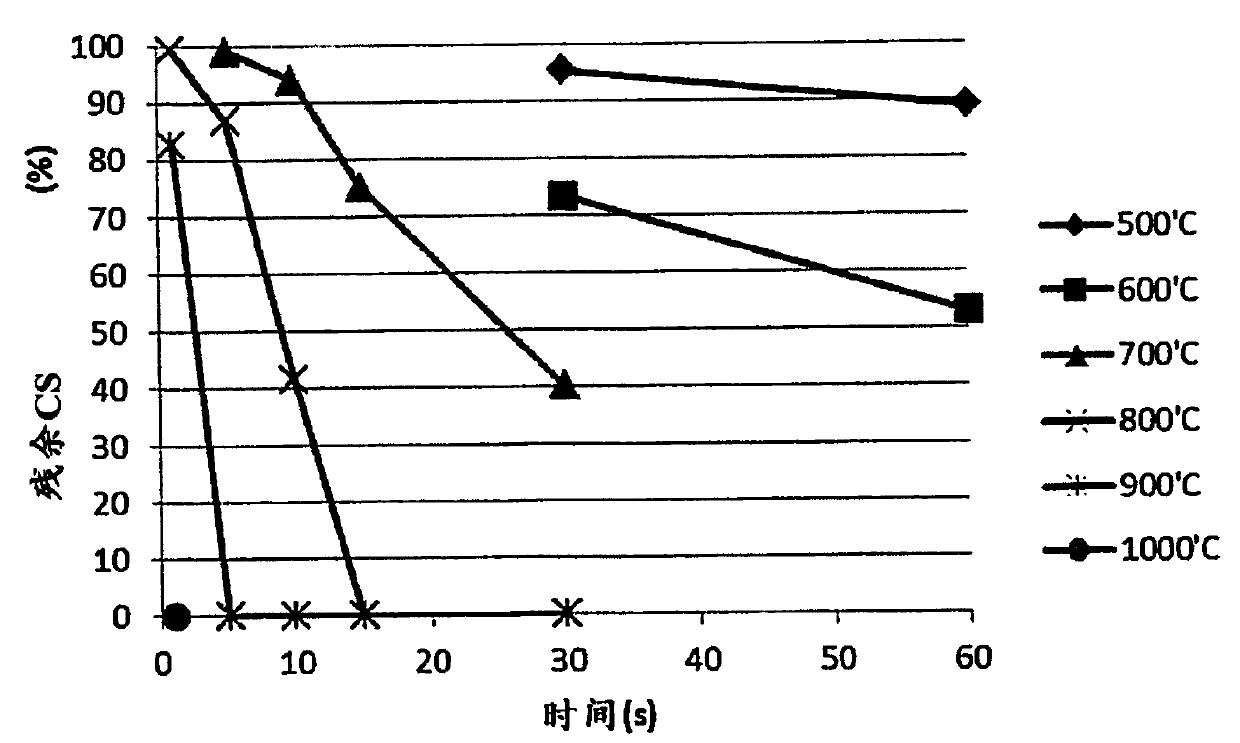

[0144] Examples 5 and 6 contain samples with a single / double-sided functional coating according to configuration A (A), wherein no additional layers are applied. As can be gleaned from Table 3 above, Example 5 has a medium DoL, while Example 6 has a large DoL. The residual compressive stress CS of Example 5 残余 is 96%, and the residual DoL 残余 is 104%, while the CS of Example 6 残余 then 100% and DoL 残余 96%.

[0145] Examples 7 to 8

[0146]

example 7

[0148] Examples 7 and 8 contain samples prepared with a single layer of functional coating for comparison. A sample of Example 7 was prepared with a single silicate layer functional coating, while a sample of Example 8 was prepared with a single titania layer functional coating. As learned from the table above, the residual CS 残余 and DoL 残余 Similar values are obtained with multilayer coatings according to configuration A (A).

example 9

[0150] Example 9 contains a sample with a single-sided functional coating according to configuration A, wherein no additional layers were applied. Table 5 below shows comparative values of DoL and CS before and after curing the sol-gel coating on the coated and uncoated sides.

[0151]

[0152] Table 5: Single side coated glass samples of Example 9

[0153] The samples of Example 9 clearly show that the change in tempering parameters is not substantially affected by the presence of a coating on one side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com