Lithium nickel manganese oxide anode material of three-dimensional desert wave structure and preparing method and application of lithium nickel manganese oxide anode material

A wave structure, lithium nickel manganese oxide technology, applied to structural parts, battery electrodes, electrical components, etc., can solve problems such as poor cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

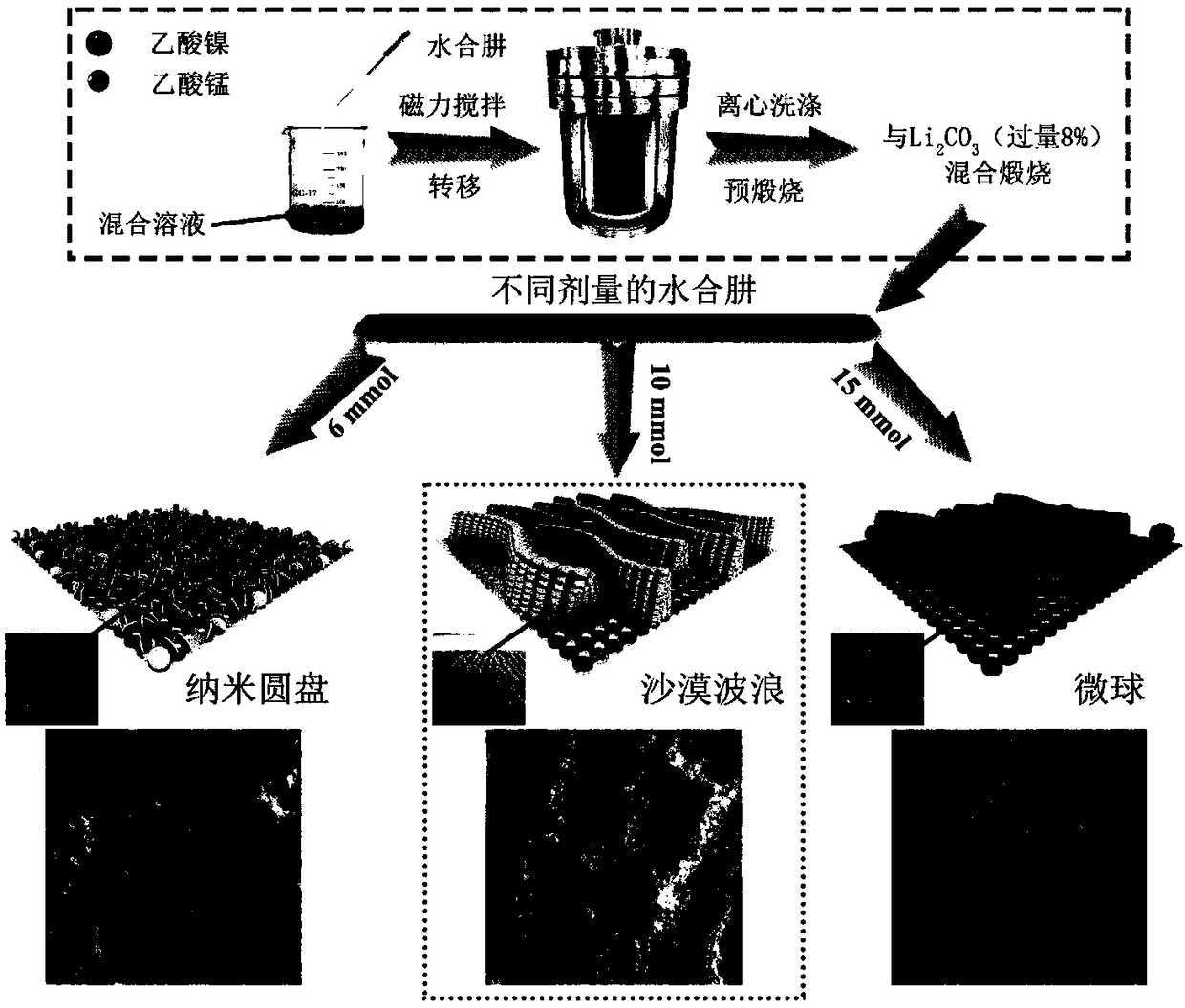

[0033] The invention provides a method for preparing a lithium nickel manganese oxide cathode material with a three-dimensional desert wave structure, comprising the following steps:

[0034] (1) Nickel acetate tetrahydrate, manganese acetate tetrahydrate, water and ethylene glycol are mixed to obtain a mixed solution;

[0035] (2) After adding hydrazine hydrate dropwise to the mixed solution obtained in the step (1), carry out a hydrothermal reaction to obtain a nickel-manganese precursor;

[0036] (3) pre-calcining the nickel-manganese precursor obtained in the step (2) to obtain a pre-calcined product;

[0037] (4) the mol ratio of the precalcined product that described step (3) obtains and the lithium element in lithium carbonate, the nickel element in nickel acetate tetrahydrate and the manganese element in manganese acetate tetrahydrate is 1.03~1.08:0.5: 1.5 Lithium carbonate is mixed and calcined by process control to obtain a three-dimensional desert wave structure li...

Embodiment 1

[0069] (1) 0.5mmolNi(CH 3 COO) 2 4H 2 O and 1.5mmolMn(CH 3 COO) 2 4H 2 O and 3.5mL ethylene glycol were dissolved in 21mL deionized water to obtain a raw material mixture;

[0070] (2) Add 5 mmol of hydrazine hydrate solution dropwise to the raw material mixture under stirring, and the dropping time is 10 minutes; after the dropping is completed, continue to stir for 30 minutes to obtain a suspension;

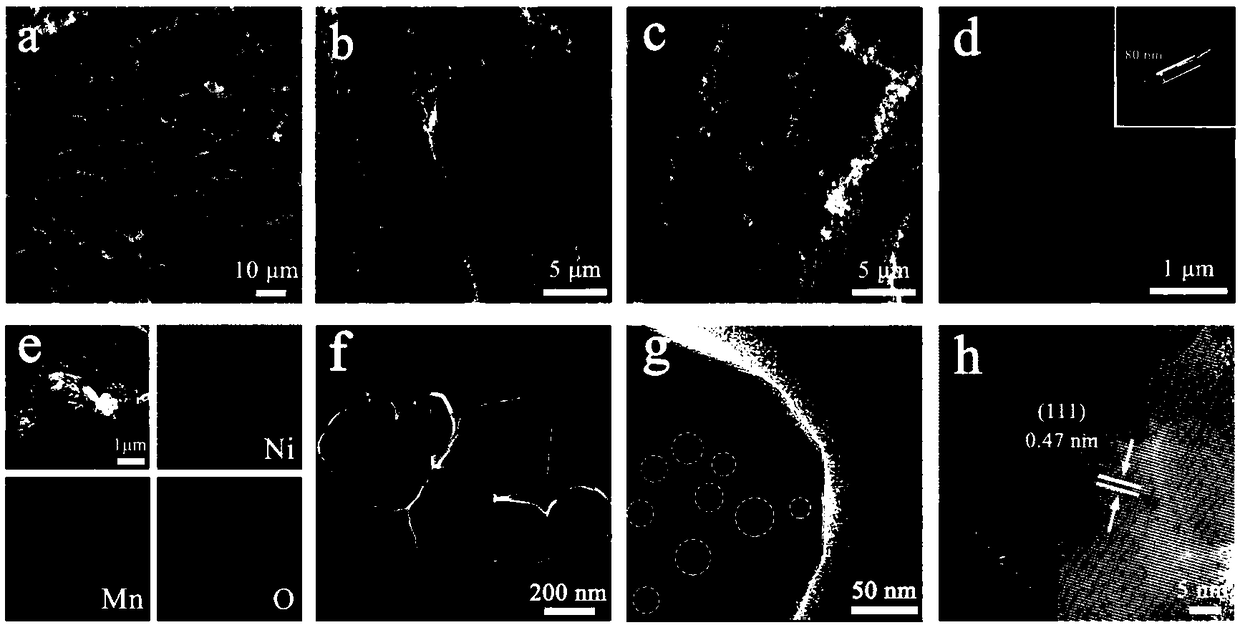

[0071] (3) Transfer the suspension to a hydrothermal reaction kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 190°C, and the time of the hydrothermal reaction is 12h; after the hydrothermal reaction is completed, the reaction kettle is cooled to room temperature Finally, through centrifugation, the precipitate was obtained; the precipitate was washed twice with distilled water and absolute ethanol, and a 50mL centrifuge tube was used to carry out centrifugal washing at a speed of 7500rpm, with 25-35mL of water for each washing; the washed ...

Embodiment 2

[0085] (1) 0.5mmolNi(CH 3 COO) 2 4H 2 O and 1.5mmolMn(CH 3 COO) 2 4H 2 O and 7mL ethylene glycol are dissolved in 42mL deionized water to obtain a raw material mixture;

[0086] (2) Add 6 mmol of hydrazine hydrate solution dropwise to the raw material mixture in a stirring state, and the dropping time is 10 minutes; after the dropping is completed, continue to stir for 30 minutes to obtain a suspension;

[0087] (3) Transfer the suspension to a hydrothermal reaction kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 190°C, and the time of the hydrothermal reaction is 12h; after the hydrothermal reaction is completed, the reaction kettle is cooled to room temperature Finally, through centrifugation, the precipitate was obtained; the precipitate was washed twice with distilled water and absolute ethanol, and a 50mL centrifuge tube was used to carry out centrifugal washing at a speed of 7500rpm, with 25-35mL of water for each washing; the washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com