Method for preparing conductive polymers ordered nano film

A conductive polymer and nano-film technology, applied in the field of polymer materials, can solve the problems of reducing the conductivity of conductive polymers, affecting the carrier migration rate, unable to obtain a layered structure, etc., achieving rapid adsorption and desorption, easy Operation, effect of device performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] exist figure 1 The concentration of oxidant ions in the subphase must reach a certain concentration, and when it is converted into oxidant active sites in the solid film, there will be sufficient oxidant concentration in the film. The surface of the substrate is treated with hydrophilicity. Then the surfactant octadecanoic acid chloroform solution is added dropwise on the surface of the subphase, and after the chloroform volatilizes, the sliding barrier 5 is controlled to compress the monomolecular film at a certain speed, and after reaching the required surface pressure, keep the molding pressure constant for a period of time, and then control The substrate transfers the composite film to the surface of the substrate at a certain speed.

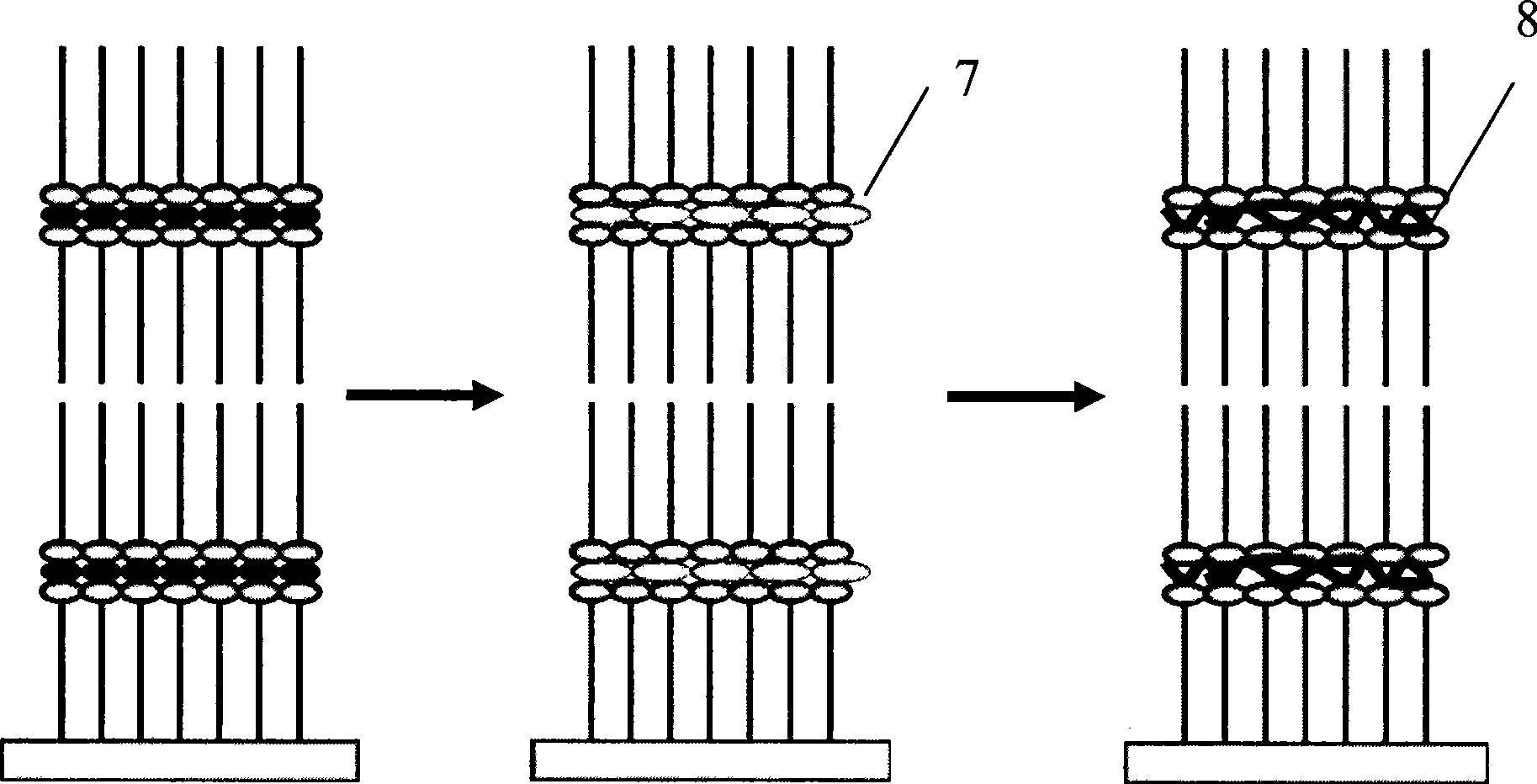

[0050] exist figure 2 in, by figure 1 The obtained multilayer ordered film is firstly exposed to an airtight atmosphere containing oxidizing gas to obtain a multilayer ordered film containing oxidant active sites.

[0051] exist ...

Embodiment 2

[0062] Such as figure 2 , the surfactant material is octadecanoic acid, and the surface of the substrate is treated with hydrophobicity.

[0063] The preparation process of the ordered nano-film structure is similar to Embodiment 1. Since the surface of the substrate is treated with hydrophobicity, the following ordered nano-film structure is obtained:

[0064] Substrate / single octadecyl chain / {3,4-polyethylenedioxythiophene / double octadecyl chain / 3,4-polyethylenedioxythiophene} n , n is determined by the number of layers of the film.

Embodiment 3

[0066] Such as figure 2 , the surfactant material is eicosanoic acid, and the surface of the substrate is treated with hydrophilicity.

[0067] The preparation process of the ordered nano-film structure is similar to Embodiment 1. Since the surface of the substrate is treated hydrophilically, the following ordered nano-film structure is obtained:

[0068] Substrate / {3,4-polyethylenedioxythiophene / double eicosyl chain / 3,4-polyethylenedioxythiophene} n, n is determined by the number of layers of the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com