Spray-free polypropylene material with marble black and white grains and preparation method thereof

A polypropylene material, spray-free technology, applied in the field of spray-free polypropylene material and its preparation, can solve the problems of inability to form black spots, black clouds and wire drawing, and achieves easy realization of process operation, reduced complexity, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the spray-free polypropylene material with marble black and white texture comprises the following steps:

[0038] 1) Preparation of matrix PP: Stir and mix barium sulfate and additives first, then add PP resin and toughening agent and stir and mix. The mixture is extruded through a twin-screw extruder and granulated to obtain matrix PP;

[0039] 2) Preparation of black or white masterbatch: After the lubricant is heated to melt, add black pigment or white pigment respectively, stir and mix, and grind to obtain black or white abrasive respectively; mix matrix resin and antioxidant with black or white respectively The grinding material is stirred and mixed, and the obtained black or white mixture is extruded through a twin-screw extruder, and granulated to obtain black masterbatch or white masterbatch;

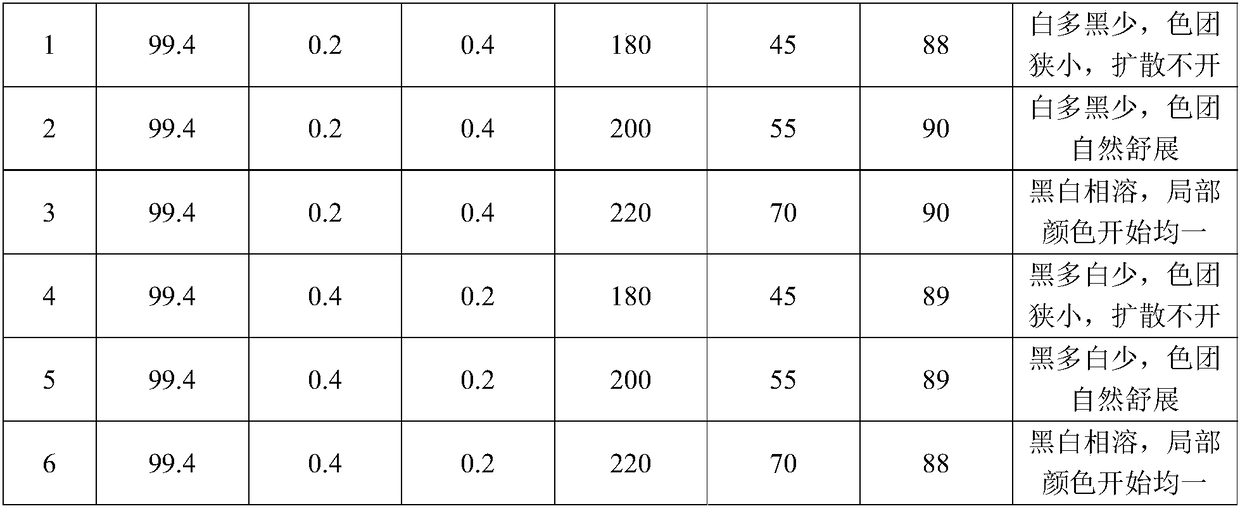

[0040] 3) Injection molding: Blend the matrix PP, black masterbatch and white masterbatch, and inject molding to obtain the above-mentioned spra...

Embodiment

[0049] 1. Preparation of matrix PP

[0050] Examples of raw materials used to prepare the base PP are as follows:

[0051] PP, Z30S, Zhenhai Refining & Chemical;

[0052] Modified precipitated barium sulfate, AB-03N, commercially available;

[0053] Epoxy resin 7072, commercially available;

[0054] Antioxidant, Irganox 1010, Irganox 168, BASF;

[0055] EBS, produced in Malaysia, commercially available;

[0056] Activated calcium carbonate, Bai Yanhua, Jiangxi Gaofeng Chemical Industry.

[0057] In terms of mass percentage, in the matrix PP, PP accounts for 85%, modified precipitated barium sulfate accounts for 15%, epoxy resin 7072 accounts for 2%, antioxidant 1010 accounts for 0.5%, antioxidant 168 accounts for 0.5%, and EBS accounts for 0.8% %, active calcium carbonate accounts for 1.2%.

[0058] The preparation method is as follows: After the modified precipitated barium sulfate and other additives are passed through the high-speed mixer, they are put into the high-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com