Synthetic method of propylene glycol butyl ether acetate

A technology of propylene glycol butyl ether and a synthesis method, applied in the field of fine chemicals, can solve the problems of dehydration and oxidative side reactions, difficult separation of products and catalysts, corrosion of equipment, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

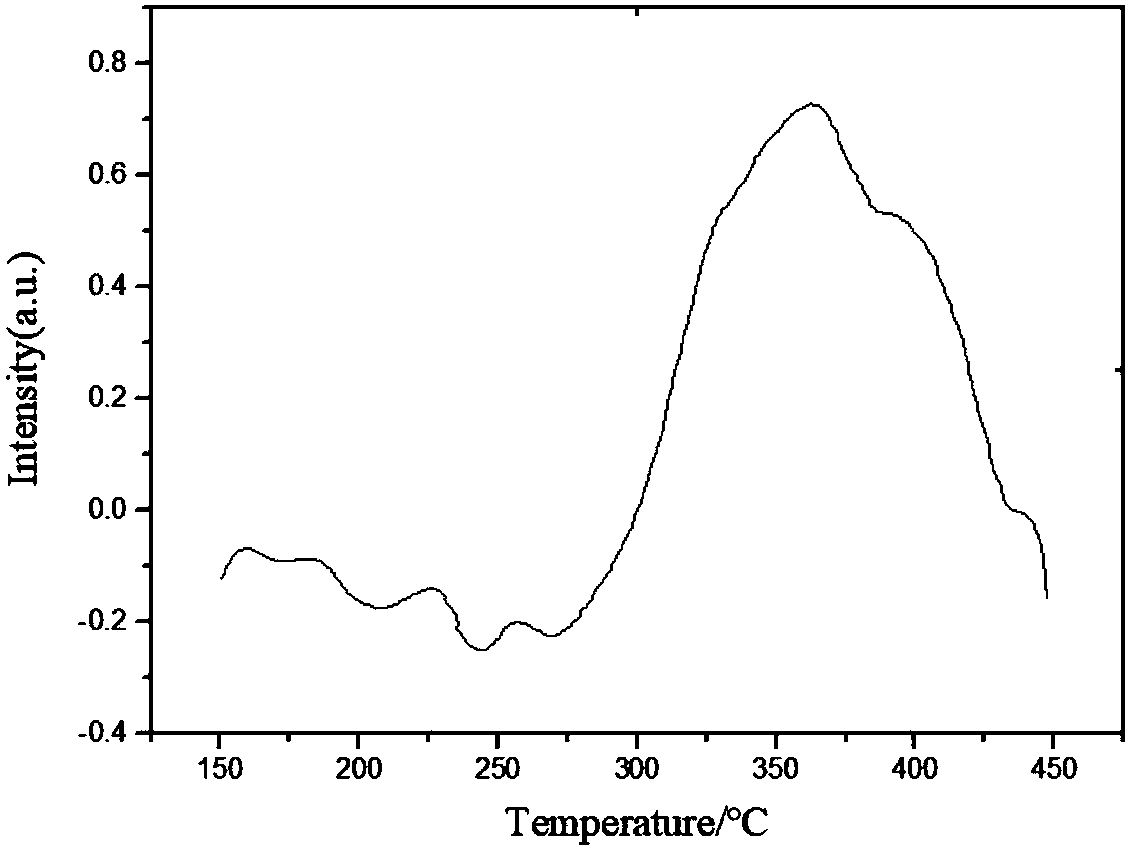

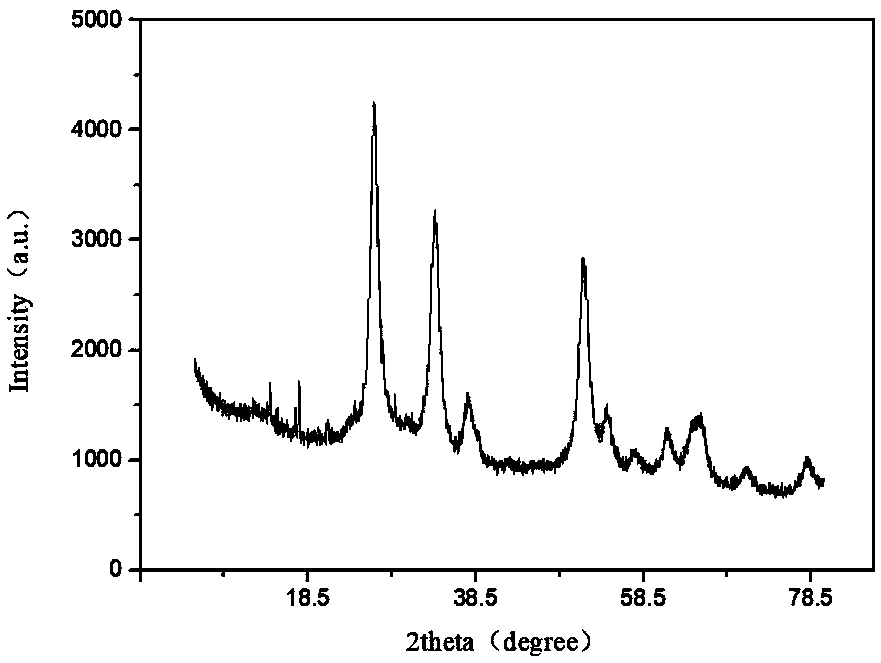

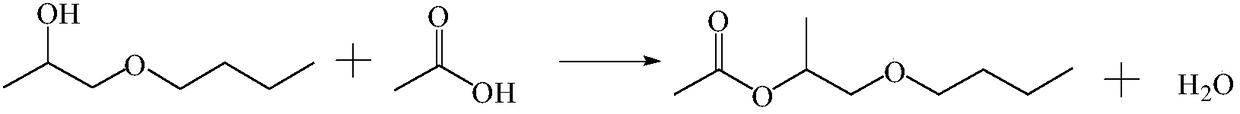

Method used

Image

Examples

Embodiment 1

[0023] Add 132.23g of propylene glycol butyl ether, 90.08g of acetic acid, 2.22g of catalyst and 66.69g of water-carrying agent into a 500mL four-neck flask, heat up to the reaction reflux, control the reaction temperature at 135°C, and promptly separate it into the water separator of water. The conversion rate of propylene glycol butyl ether was 47.47%, and the yield of propylene glycol butyl ether acetate was 42.34%.

Embodiment 2

[0025] Add 132.23g of propylene glycol butyl ether, 90.08g of acetic acid, 2.22g of catalyst and 66.69g of water-carrying agent into a 500mL four-neck flask, heat up to the reaction reflux, control the reaction temperature at 140°C, and promptly separate it into the water separator of water. The conversion rate of propylene glycol butyl ether was 65.09%, and the yield of propylene glycol butyl ether acetate was 58.81%.

Embodiment 3

[0027] Add 132.23g of propylene glycol butyl ether, 90.08g of acetic acid, 2.22g of catalyst and 66.69g of water-carrying agent into a 500mL four-neck flask, heat up to the reaction reflux, control the reaction temperature at 145°C, and promptly separate it into the water separator of water. The conversion rate of propylene glycol butyl ether was 81.31%, and the yield of propylene glycol butyl ether acetate was 76.51%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com