Low-temperature sintering high-dielectric-property Y5V type ceramic capacitor dielectric material and preparation method thereof

A technology of ceramic capacitors and dielectric materials, which is applied in the field of chemical new functional materials, can solve the problems of component segregation and low dielectric constant of BT-based ceramics, and achieve the effects of low dielectric loss, excellent dielectric properties and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to the composition formula:

[0029] Ba(Zr x Ti 1-x )O 3 +A(ZnO+CeO 2 +CuO+MnO 2 +Sm 2 o 3 +Nb 2 o 5 )+yLi 2 o

[0030] y=0.34wt%~1.36wt%,

[0031] Among them, 0.1≤x≤0.3, MnO 2 0.2%, CeO 2 0.15%, Nb 2 o 5 1.2%, ZnO 1.1%, Sm 2 o 3 0.14%, CuO 0.8%.

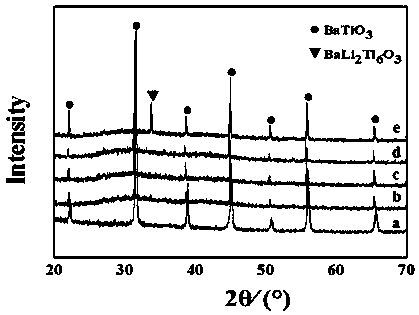

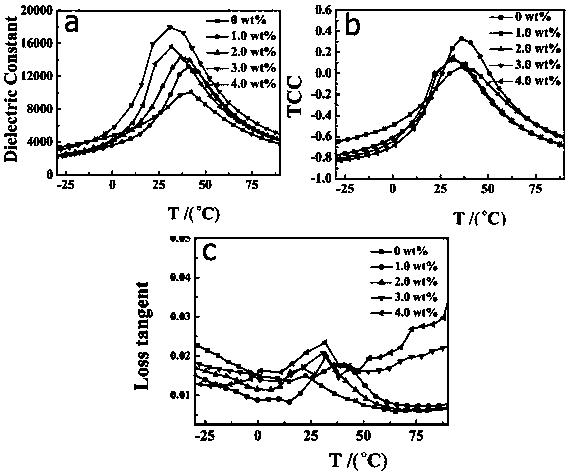

[0032] The barium zirconate titanate-based powder was synthesized by the sol-gel method, the calcining temperature of the powder was 900°C, (y was 0.34wt%, 0.68%, 1.02%, and 1.36% samples were recorded as #1, # 2. #3 and #4) The specific steps for preparing powder and its ceramic dielectric material are as follows:

[0033] a) Weigh 150g Ti(OBu) according to the stoichiometric ratio 4 , slowly add 15ml of glacial acetic acid and 8ml of absolute ethanol and mix and stir at room temperature to obtain a yellow transparent solution, then add 13.20g of Ba(CH 3COO) 2 , 0.3g Zr(NO 3 ) 4 ·5H 2 O, 0.24 (NO 3 ) 3 ·6H 2 O,0.25gZn(CH 3 COO) 2 2H 2 O,0.08g Cu(CH 3 COO) 2 ·H 2 O and 0.24gMn(CH 3 ...

Embodiment 2

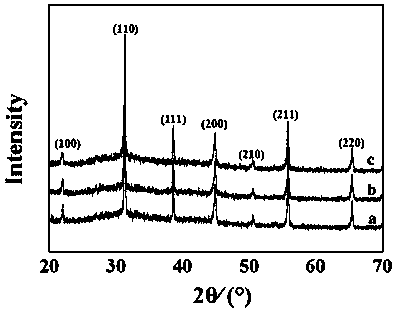

[0038] According to the composition formula:

[0039] Ba(Zr x Ti 1-x )O 3 +yLi 2 o

[0040] Wherein y=0.34wt%~1.36wt%, 0.1≤x≤0.3. Choose x=0.1, y=1.02wt%. The barium zirconate titanate-based powder was synthesized by the sol-gel method. The pre-sintering temperature of the powder was 900°C, and the ceramic sintering temperatures were 1050°C, 1110°C and 1150°C respectively (denoted as #3-1, #3- 2 and #3-3), the specific steps are as follows: Weigh 10.0g main crystal phase powder, 3.0wt% Li 2 CO 3 After adding water, ball mill for 6-12 hours to obtain ceramic powder slurry, and dry the powder slurry at 100° C. to obtain barium zirconate titanate-based powder. The barium zirconate titanate-based powder obtained after ball milling was granulated, and pressed into 8mm discs under a pressure of 6 MPa, and the discs were sintered at different temperatures and held for 2 hours to make ceramics. The ceramic discs were coated with silver paste on both sides and then kept at 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com