Pantograph carbon sliding plate and preparation method thereof

A pantograph carbon slide plate and carbon bar technology, which is applied in the field of important vehicle parts, can solve problems such as the decrease in the strength of the bonding layer, and achieve the effect of high strength and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

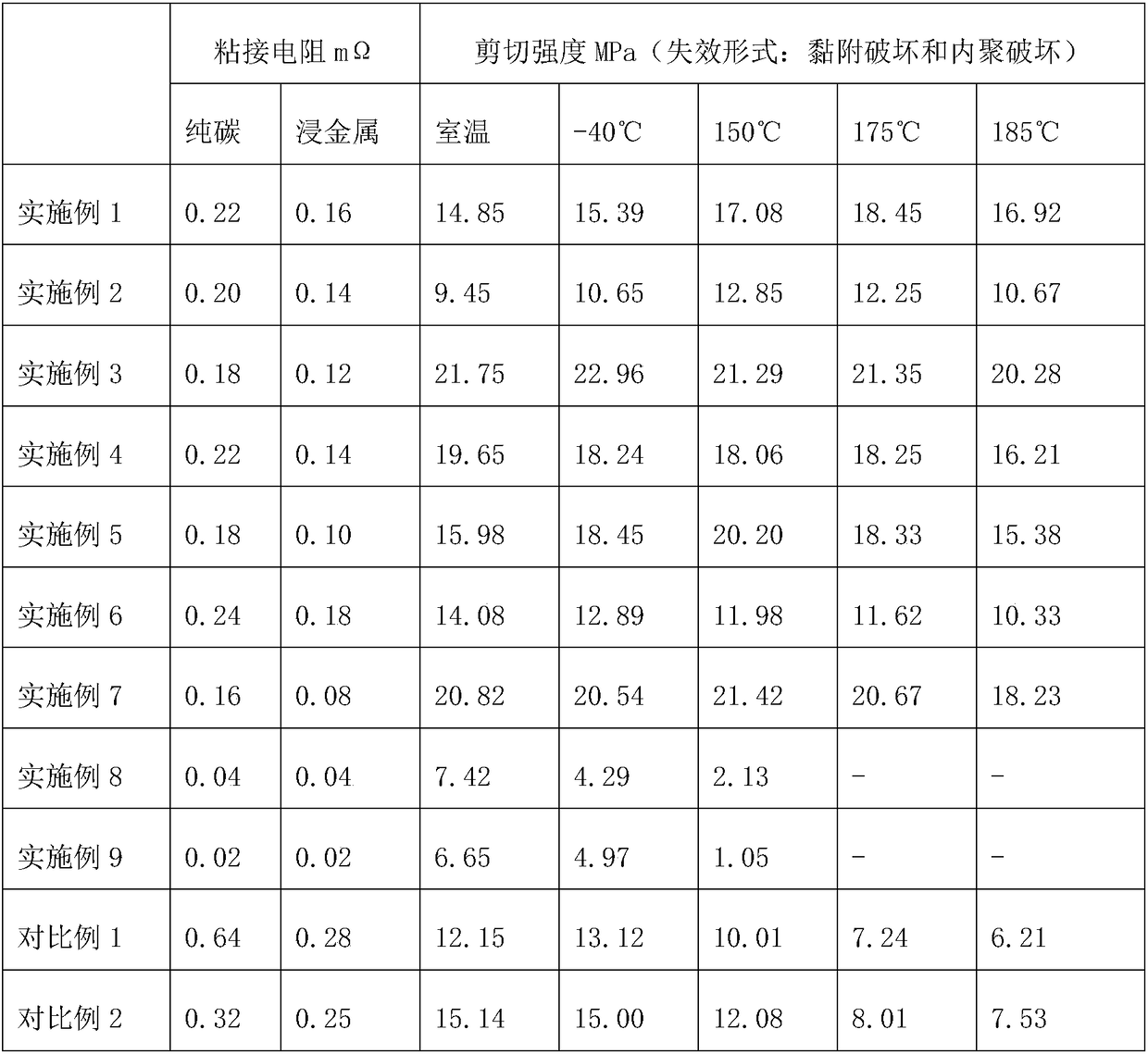

Examples

Embodiment 1

[0026] A pantograph carbon sliding plate, which sequentially includes an aluminum bracket, a bonding layer and a carbon strip. The raw materials for forming the bonding layer are composed of: phenolic epoxy resin 40g, dicyclopentadiene phenol epoxy resin 20g, 2 -16g of methyl-4-ethylimidazole, 55g of 200 mesh copper powder, and 7g of 30 mesh copper powder.

[0027] First, melt and blend the novolac epoxy resin and dicyclopentadiene phenol epoxy resin, and stir until they are uniform for later use; mix the aforementioned mixed resin with 2-methyl-4-ethylimidazole and copper powder evenly before use. Binder.

[0028] After coating the adhesive on the aluminum bracket, the carbon strip is adhered and cured at 70° C. to form a pantograph carbon sliding plate.

Embodiment 2

[0030] A pantograph carbon sliding plate, which in turn includes an aluminum bracket, a bonding layer and a carbon strip. The raw materials for forming the bonding layer are composed of 70 g of phenolic epoxy resin and 13 g of dicyclopentadiene phenol epoxy resin. -10 g of methyl-4-ethylimidazole, 35 g of 150 mesh copper powder, and 6 g of 35 mesh copper powder.

[0031] First, melt and blend the novolac epoxy resin and dicyclopentadiene phenol epoxy resin, and stir until they are uniform for later use; mix the aforementioned mixed resin with 2-methyl-4-ethylimidazole and copper powder evenly before use. Binder. After coating the adhesive on the aluminum bracket, the carbon strip is adhered and cured at 80° C. to form a pantograph carbon sliding plate.

Embodiment 3

[0033] A pantograph carbon slide plate, which sequentially includes an aluminum bracket, a bonding layer and a carbon strip. The raw materials for forming the bonding layer are composed of 50 g of phenolic epoxy resin, 10 g of dicyclopentadiene phenol epoxy resin, and 2 -Methyl-4-ethylimidazole 14g, 100 mesh copper powder 60g, 40 mesh copper powder 8g.

[0034] First, melt and blend the novolac epoxy resin and dicyclopentadiene phenol epoxy resin, and stir until they are uniform for later use; mix the aforementioned mixed resin with 2-methyl-4-ethylimidazole and copper powder evenly before use. Binder.

[0035] After coating the adhesive on the aluminum bracket, the carbon strip is adhered and cured at 90° C. to form a pantograph carbon sliding plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com