Wafer and wafer testing method

A testing method and wafer testing technology, applied in semiconductor/solid-state device testing/measurement, electrical components, electrical solid-state devices, etc., can solve the problem of reduced utilization of wafer testing machines and incompatibility testing of traditional wafers and wafers Increased test costs and other issues, to achieve the effect of providing versatility and utilization, multiple times of reuse, and reducing the risk of wafer damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

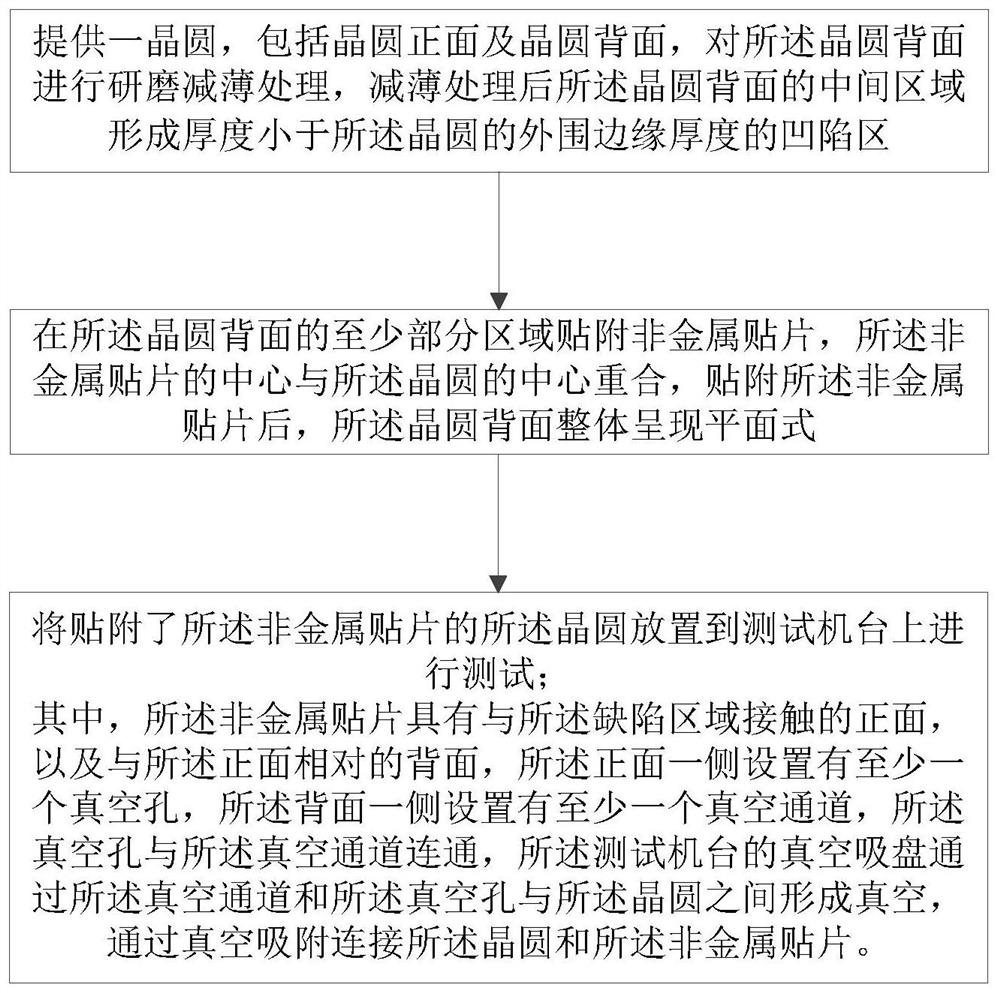

[0092] In order to overcome the problems such as the low utilization rate of the wafer test machine and the increase of test cost caused by the equipment transformation done for testing the Taiko wafer in the prior art, the present embodiment provides a wafer test method, such as image 3 As shown, the method includes the following steps:

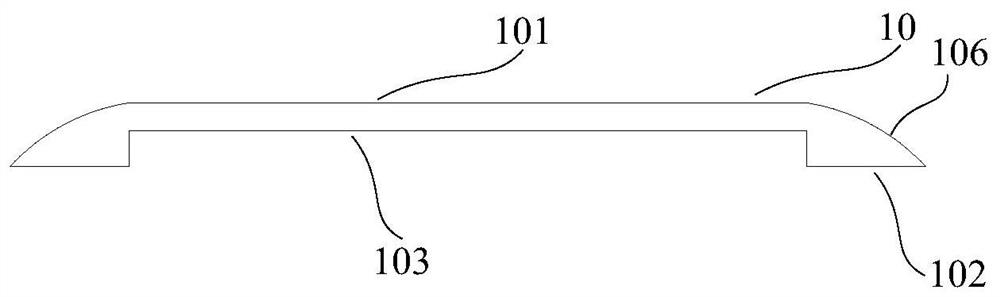

[0093] A wafer is provided, including a wafer front and a wafer back, and the back of the wafer is ground and thinned. After the thinning, the middle area of the back of the wafer is formed with a thickness smaller than that of the peripheral edge of the wafer. depressed area;

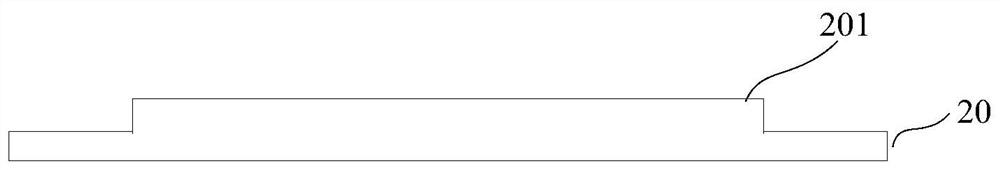

[0094] A non-metallic patch is attached to at least part of the area on the back of the wafer, the center of the non-metallic patch coincides with the center of the wafer, and after the non-metallic patch is attached, the entire back of the wafer present a flat form;

[0095] placing the wafer attached with the non-metal patch on a testing machine for testing; ...

Embodiment 2

[0108] This embodiment also provides a wafer testing method, and the similarities with Embodiment 1 will not be repeated, but the differences are:

[0109] Such as Figure 9 As shown, the wafer 90 provided in this embodiment has a wafer front 901 and a wafer back 902 , and the middle area of the wafer back 902 has a recessed area 903 . The backside 902 of the wafer is attached with a non-metal patch 60 . Such as Figure 10 As shown, the non-metallic patch 60 has a front surface 601 in contact with the wafer backside 902 of the wafer 90 and a backside 602 opposite to the real surface 601. The nonmetallic patch 60 includes a cylindrical bottom 61 and a bottom surface along the bottom. 607 extends upwardly in a direction perpendicular to the bottom 607 to form a cylindrical protrusion 606 . In this embodiment, the protruding portion 606 fills the recessed area 903 on the backside of the wafer 90 . still refer to Figure 10 and combine as Figure 11 and 12 As shown, in th...

Embodiment 3

[0114] This embodiment provides a wafer, including a wafer, the wafer has a wafer front and a wafer back, the middle area of the wafer back has a recessed area, and the thickness of the recessed area is smaller than that of the wafer. peripheral edge thickness; and

[0115] A non-metallic patch attached to at least a partial area of the backside of the wafer, the center of the metal patch coincides with the center of the wafer, and after the metal patch is attached, the backside of the wafer presents an overall Plane;

[0116] Wherein, the metal patch has a front surface in contact with the defect area, and a back surface opposite to the front surface, at least one vacuum hole is provided on one side of the front surface, and at least one vacuum channel is provided on the back side, The vacuum hole communicates with the vacuum channel.

[0117] In another preferred embodiment of this embodiment, the backside of the wafer further includes a thin metal layer formed by gold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com