A workpiece coating system

A workpiece and coating technology, which is applied in the field of large-scale workpiece coating production equipment, can solve problems such as limited working space, high failure rate, and difficult maintenance, and achieve the effects of simple processing, troubleshooting, and reduced installation accuracy and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

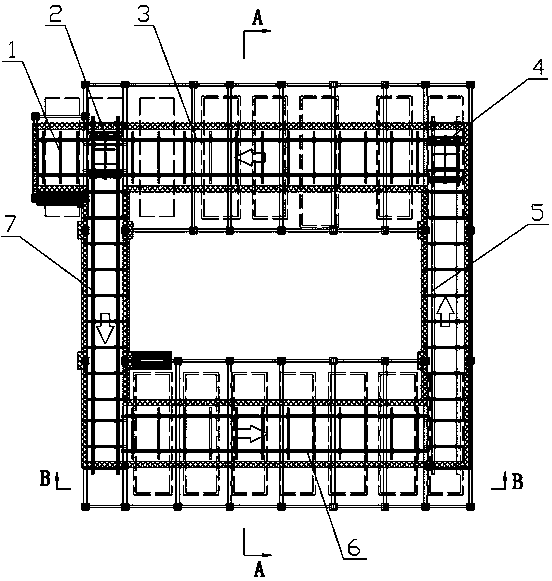

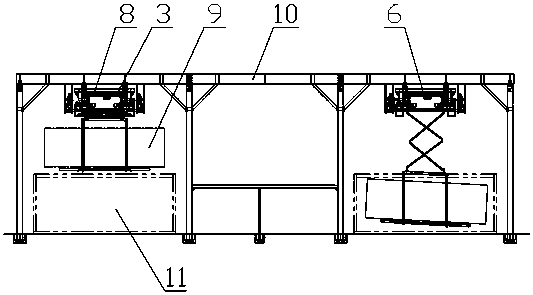

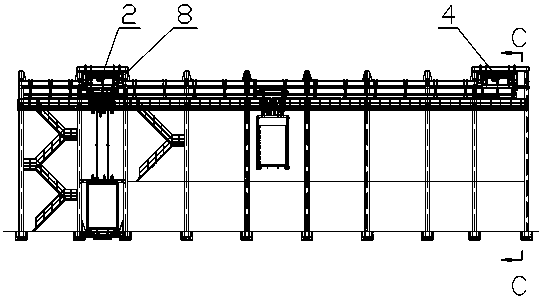

[0048] see Figure 1-Figure 20 , the present invention is a kind of workpiece coating system, has frame 10, and the left and right sides of frame are provided with traveling track A7 and moving track B5 in parallel, and the front and rear sides of frame are provided with process track A6 and process track B3 in parallel, There is a maintenance station track 1 on the outside of the moving track A, and the maintenance station track is arranged opposite to either the process track A or the process track B. The moving track A is equipped with a moving trolley A2, and the moving track B is set There is a moving trolley B4, and a double-track trolley 8 is installed on the process track A or process track B. The double-track trolley passes through the transition trolley A, process track A, transition trolley B and process track B to form a rectangular running loop. The process track A and the process track There are also a number of process treatment pools 11 below the B. The front s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com