Solar thermal chemical absorption reaction device and system

A technology of solar thermochemistry and reaction devices, applied in the field of solar power generation, can solve the problems of increasing the complexity of system design, construction and operation, the inability to integrate solar energy and external heat sources, and the failure to fully exert the catalytic performance of catalysts, so as to achieve the goal of improving thermal efficiency. Chemical conversion performance, efficient utilization, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

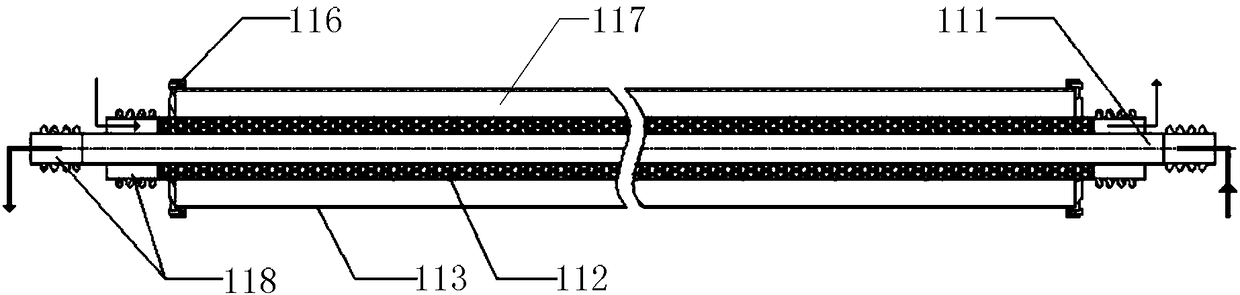

[0046] In the solar thermochemical absorption reaction device and system provided by the embodiments of the present disclosure, the adjustment of the heat transfer medium in the inner tube to absorb / release heat along the process is beneficial to the uniform distribution of the temperature of the catalyst bed and reduces the thermochemical conversion of solar energy. The thermal stress of the unit improves the working life of the solar conversion unit.

[0047] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

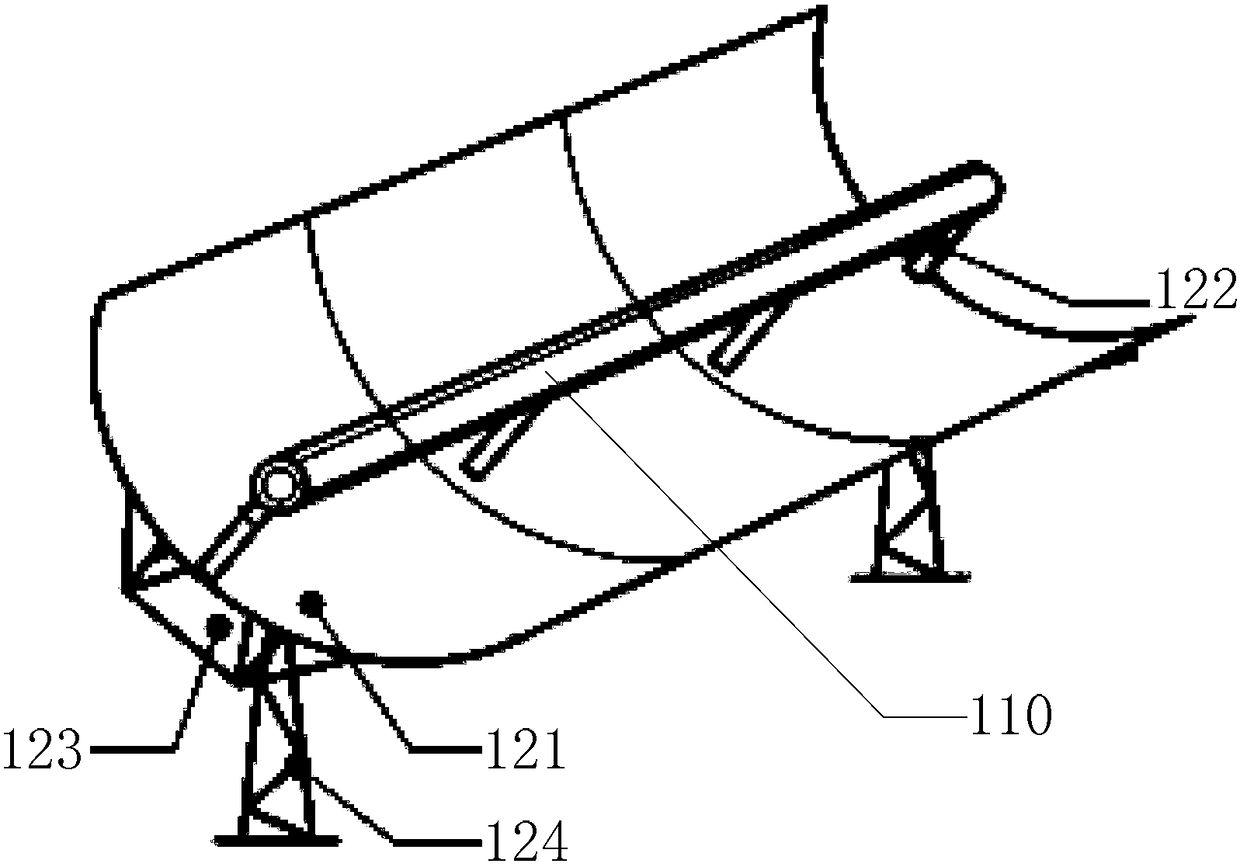

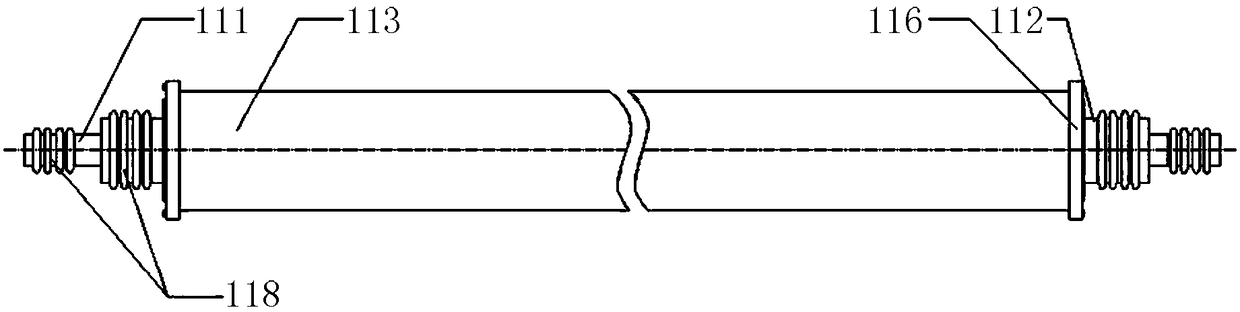

[0048] figure 1 Schematic diagram of the structure of the solar thermochemical absorption reaction device provided in this example.

[0049] According to one aspect of the present disclosure, a solar thermochemical absorption reaction device is provided, such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com