Circuit board partition block seamless laser processing method for thick gas electron multiplier

A technology of gas electron multiplication and laser processing method, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems such as the decrease of the concentricity between the insulating ring and the through hole, the etching of the insulating ring is not clean, and the impact on the product yield. Achieve the effects of reducing processing complexity and material consumption, avoiding insulation etching failure, and avoiding quality hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

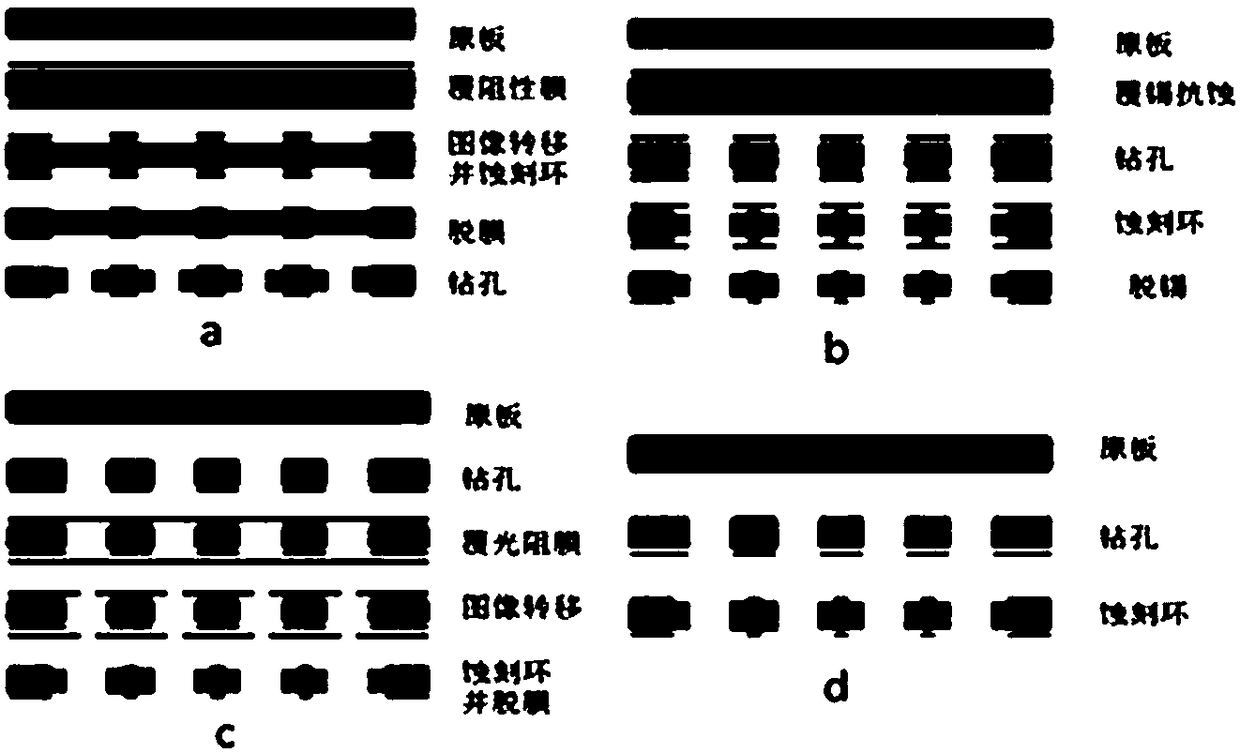

Method used

Image

Examples

Embodiment 1

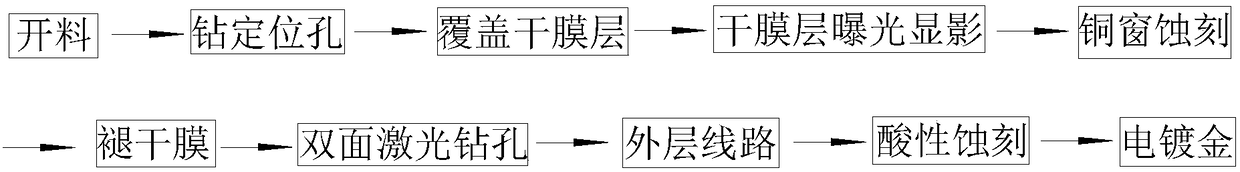

[0036] like figure 2 , image 3 and Figure 4 As shown, the block-by-block seamless laser processing method for a thick gas electron multiplier circuit board includes the following steps:

[0037] 1) According to the design requirements, the original plate is obtained, and the laser drilling area 2 is designed on the upper surface of the original plate, and the laser drilling area 2 is divided into four blocks 3; the block 3 and the adjacent block 3 For seamless splicing and connection, the side legs of block 3 are provided with alignment points 4;

[0038] 2) Drill positioning holes on the original plate obtained in step 1) cutting;

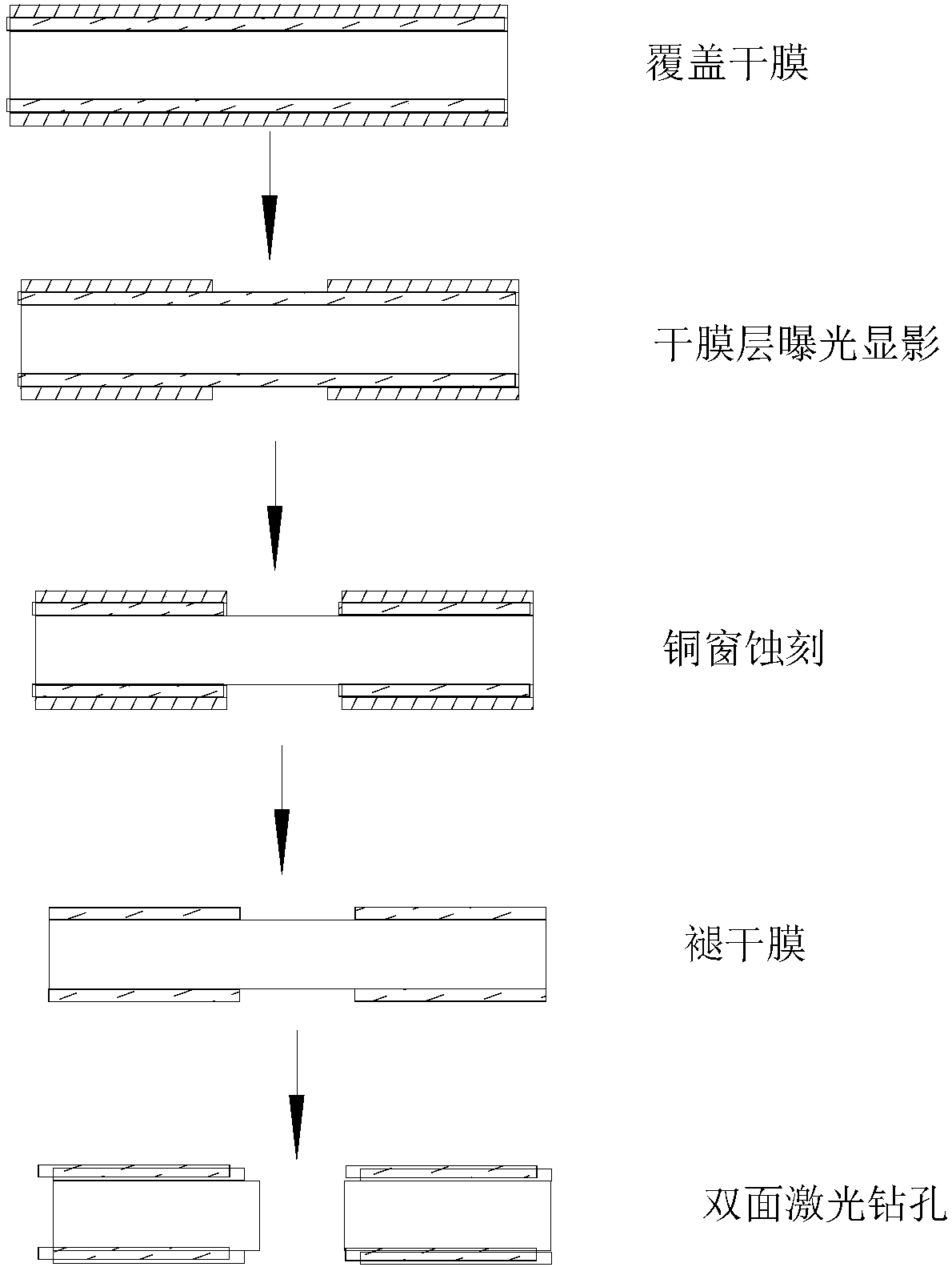

[0039] 3) Cover the dry film layer with the original plate treated in step 1), and expose and develop the dry film layer;

[0040] 4) Carry out the copper window etching of the original plate after step 3) and take off the dry film;

[0041] 5) Perform double-sided laser drilling on block 3 on the original plate after step 4) regardless of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com