A method for controlling milling parameters and tool wear of titanium alloys based on roughness

A tool wear, titanium alloy technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of poor consistency of surface morphology, difficult control of surface roughness, etc., to achieve accurate relationship model, reliable design and analysis methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The invention discloses a process control method for precision milling surface roughness of titanium alloy components, which specifically includes the following steps:

[0041]Step 1. According to the aviation manufacturing engineering manual, experience or literature, select the precision milling parameter range, design the response surface method to carry out the precision milling test, test the surface roughness after the test, and establish a surface roughness prediction model.

[0042] Step 1.1, establishing the initial process parameter domain for precision milling of titanium alloy components.

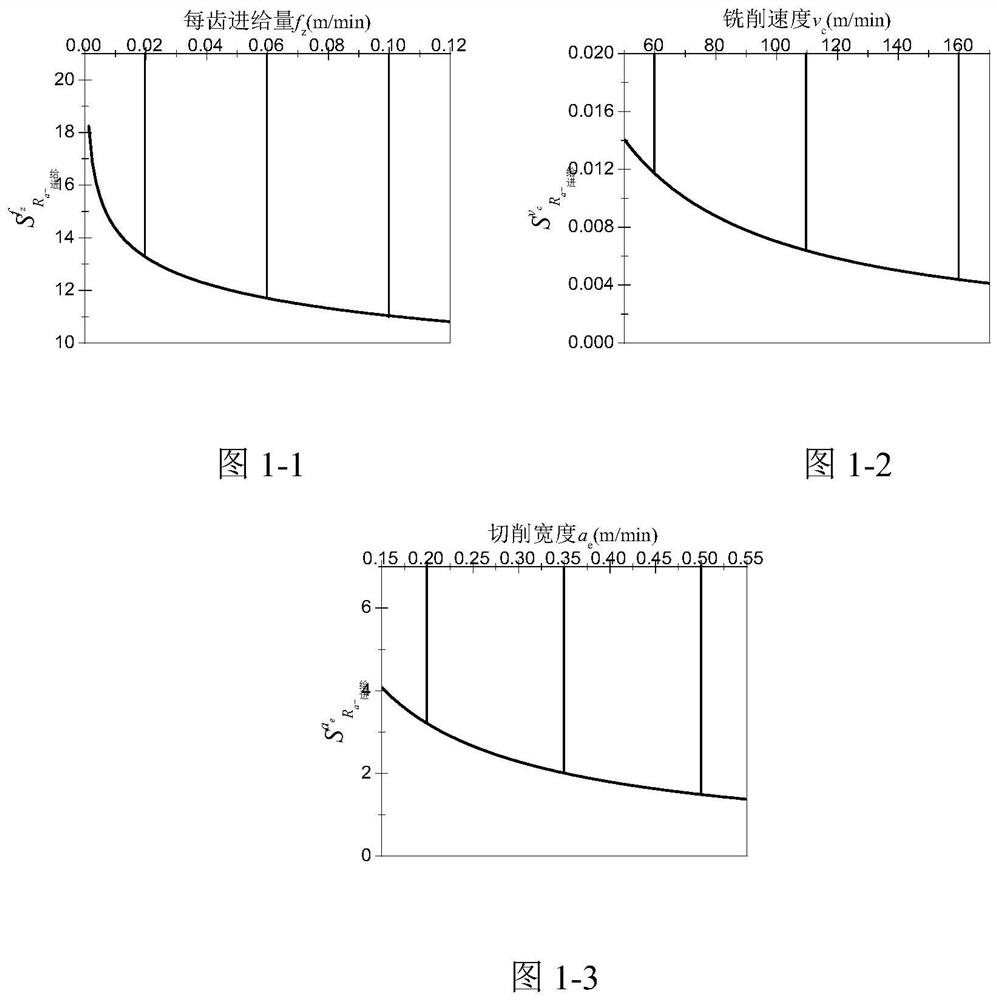

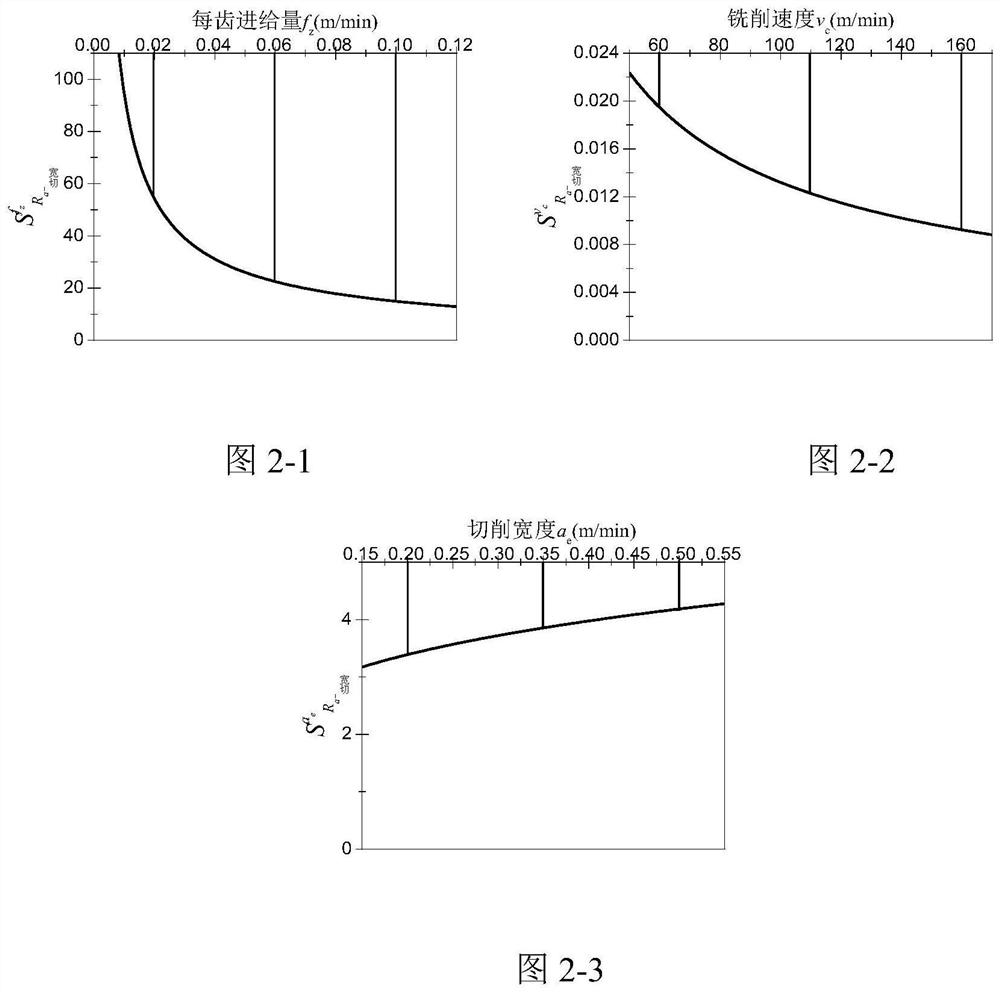

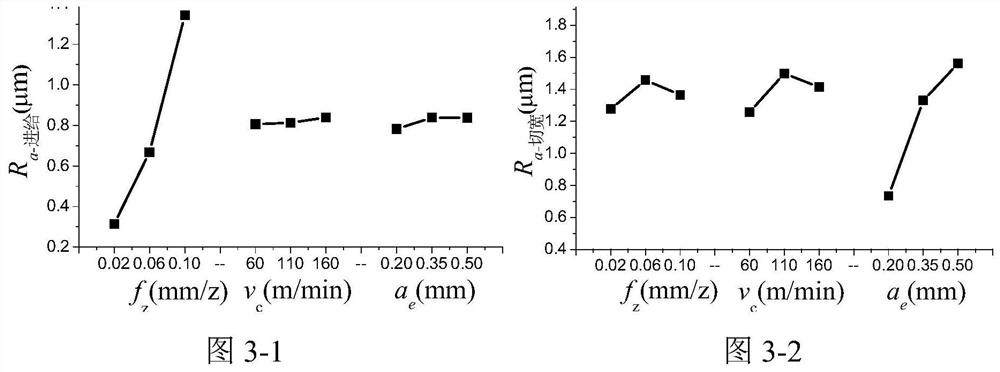

[0043] In this example, the TC17 titanium alloy is used for the test, and the precision milling process parameters of the ball end milling cutter are: milling speed [60m / min, 160m / min], feed per tooth [0.02mm / z, 0.10mm / z] , Milling widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com