Vanadium nitride powder based on liquid phase carbothermic method and preparation method of vanadium nitride powder

A vanadium nitride and powder technology, applied in the field of vanadium nitride powder, can solve the problems of being unfavorable to large-scale industrial production, increasing the production cost of vanadium nitride, low purity of vanadium nitride, etc., and achieving low cost and production cycle. Short, high-purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

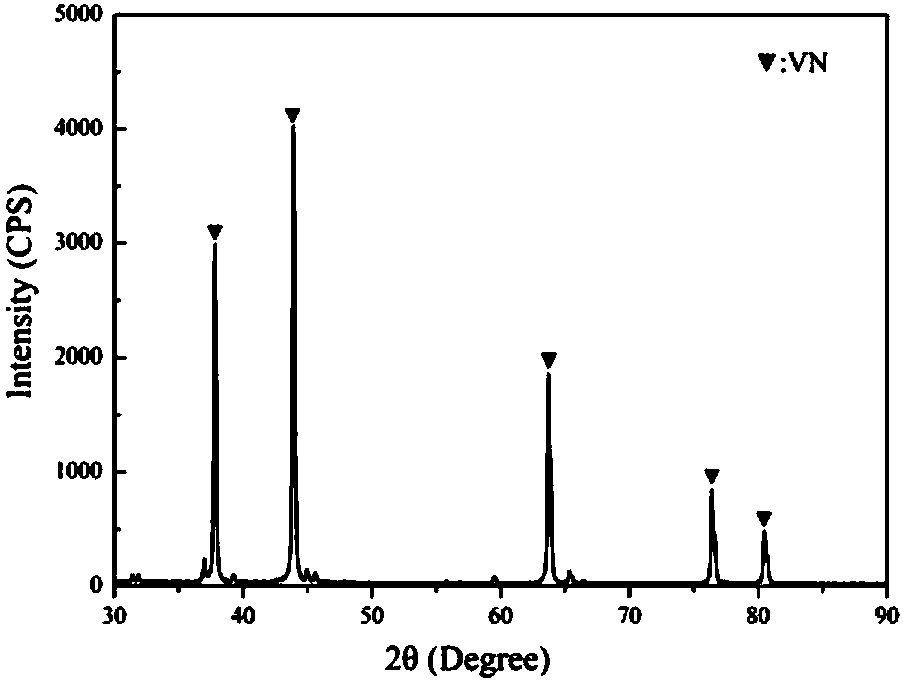

[0034] A vanadium nitride powder based on a liquid-phase carbothermal method and a preparation method thereof. The preparation method described in this embodiment is:

[0035] According to vanadium pentoxide powder: carbon powder: inorganic salt mass ratio is 1: (2 ~ 2.4): (4 ~ 4.5), the described vanadium pentoxide powder, the carbon powder and the inorganic salt are mixed , to obtain a mixed powder.

[0036] The mixed powder is kept at 900-950° C. for 2.5-3 hours in a nitrogen atmosphere, and naturally cooled to obtain a fired product.

[0037] Add the burnt product into the hydrochloric acid solution, soak for 1-2 hours, wash with distilled water for 3-5 times, and dry at 90-110°C for 8-12 hours; then place it in a muffle furnace and heat up to 450-490°C , cooled naturally to prepare vanadium nitride powder based on liquid-phase carbothermal method.

[0038] The inorganic salt is a mixture of potassium iodide and potassium fluoride; in the mixture: the mass ratio of pota...

Embodiment 2

[0040] A vanadium nitride powder based on a liquid-phase carbothermal method and a preparation method thereof. The preparation method described in this embodiment is:

[0041] According to vanadium pentoxide powder: carbon powder: inorganic salt mass ratio is 1: (2.2 ~ 2.6): (4.5 ~ 5.0), the described vanadium pentoxide powder, the carbon powder and the inorganic salt are mixed , to obtain a mixed powder.

[0042] The mixed powder is kept in a nitrogen atmosphere at 950-1000° C. for 2-2.5 hours, and naturally cooled to obtain a fired product.

[0043] Add the calcined product into hydrochloric acid solution, soak for 1-2 hours, wash with distilled water for 3-5 times, dry at 90-110°C for 8-12 hours; then place it in a muffle furnace and heat up to 470-510°C , cooled naturally to prepare vanadium nitride powder based on liquid-phase carbothermal method.

Embodiment 3

[0046] A vanadium nitride powder based on a liquid-phase carbothermal method and a preparation method thereof. The preparation method described in this embodiment is:

[0047] According to vanadium pentoxide powder: carbon powder: inorganic salt mass ratio is 1: (2.4~2.8): (5.0~5.5), described vanadium pentoxide powder, described carbon powder and described inorganic salt are mixed , to obtain a mixed powder.

[0048] The mixed powder is kept in a nitrogen atmosphere at 1000-1050° C. for 1.5-2 hours, and naturally cooled to obtain a fired product.

[0049] Add the calcined product into the hydrochloric acid solution, soak for 1-2 hours, wash with distilled water for 3-5 times, and dry at 90-110°C for 8-12 hours; then place it in a muffle furnace and heat up to 490-530°C , cooled naturally to prepare vanadium nitride powder based on liquid-phase carbothermal method.

[0050] The inorganic salt is potassium iodide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com