Inner wall grinding device for short tube

A short tube and bracket device technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of large size of grinding device, inconvenient use, and low grinding efficiency, so as to improve efficiency and prevent Float around, prevent pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

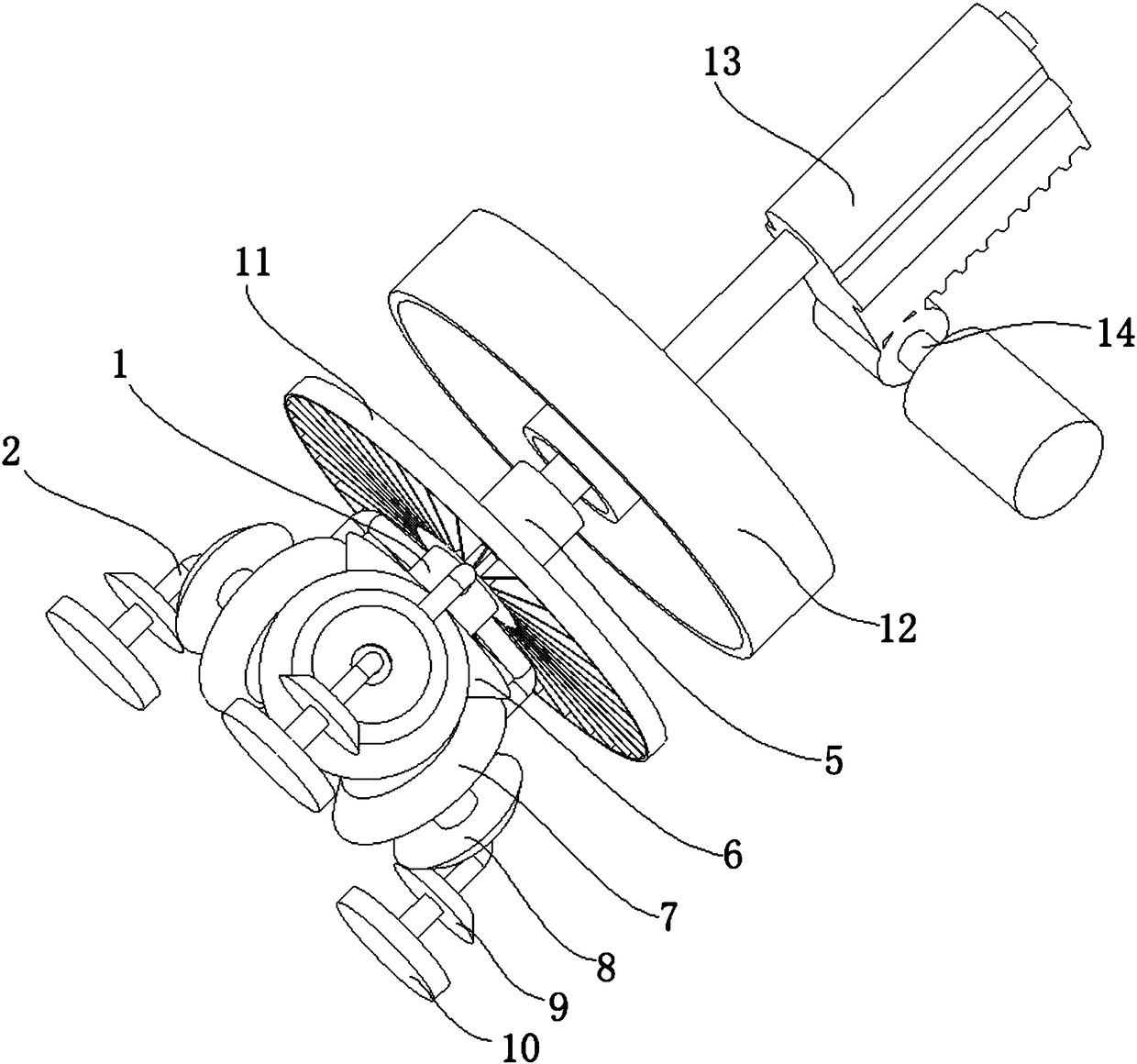

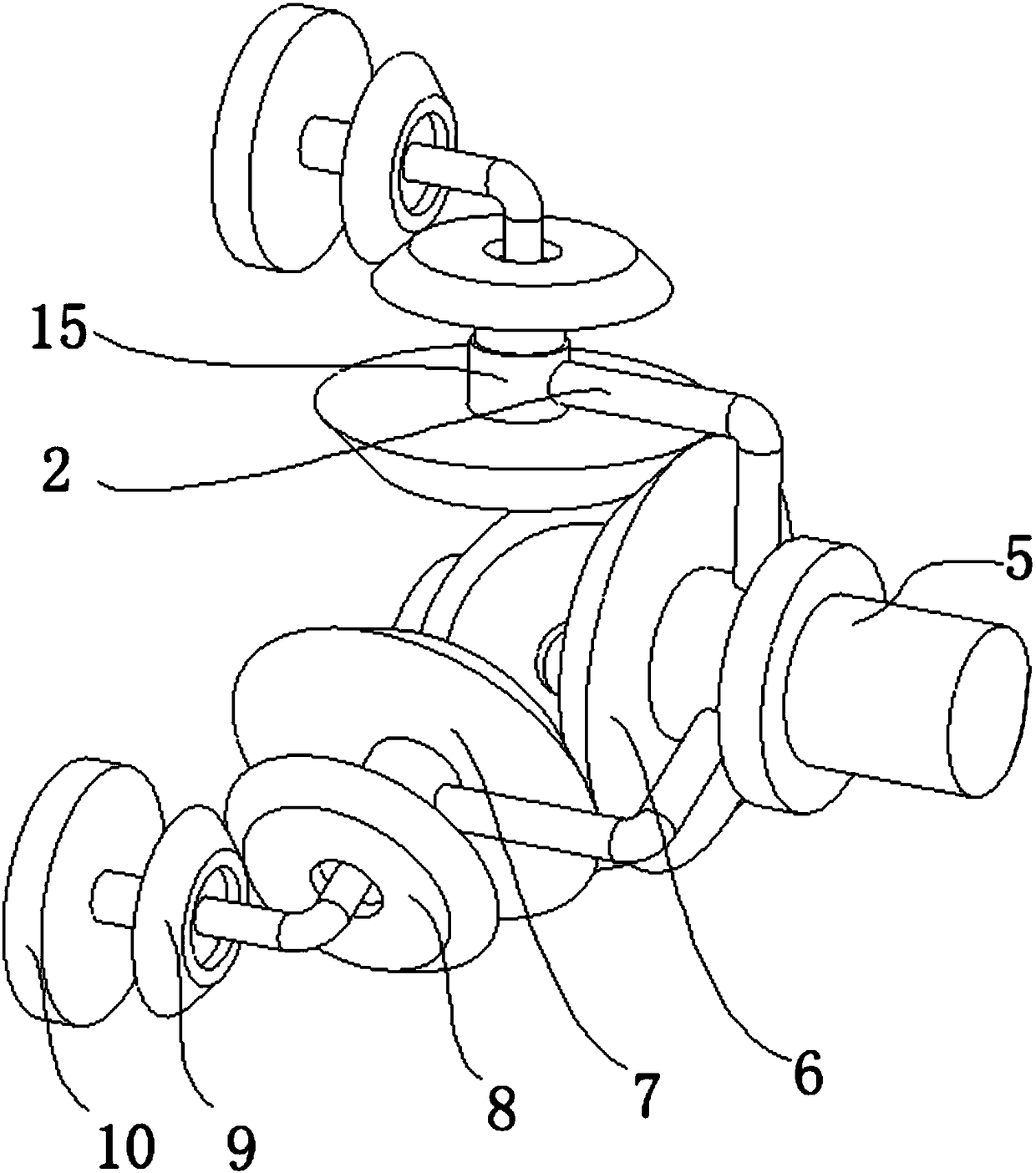

[0029] A short pipe inner wall grinding device according to an embodiment of the present invention, such as figure 1 , figure 2 and image 3 As shown, it includes: a grinding drive device 1, several rotating grinding parts 2 and a rotary feeding part, the grinding drive device 1 includes a driving motor 5, a driving bevel gear 6 and a bracket device, and the driving motor 5 and the driving bevel gear 6 are arranged on the bracket device Above, the driving motor 5 is used to drive the driving bevel gear 6 to rotate; in the present invention, in the specific application process, there are 3 rotating grinding parts 2, and the 3 rotating grinding parts 2 are evenly distributed on the central axis of the driving bevel gear 6. on the circumference of the axis;

[0030] Such as image 3 As shown, the first bevel gear 7, the second bevel gear 8, the third bevel gear 9 and the grinding runner 10 are arranged on the rotating grinding part 2, the first bevel gear 7 meshes with the dr...

Embodiment 2

[0039] Compared with Embodiment 1, Embodiment 2 is different in that the connection between the first bevel gear 7 and the second bevel gear 8 is a sleeve fitting connection, and a spring is provided in the sleeve, and the spring is used to connect the first bevel gear to the second bevel gear. The second bevel gear 8 is ejected outwards, and the adjustment of the spacing distance between the first bevel gear 7 and the second bevel gear 8 is realized by changing the compression amount of the spring, and the elastic force generated by the spring compression can provide the second bevel gear 8 1. The third bevel gear 9 and the grinding wheel 10 generate radial elastic force as a whole, and there is a certain extrusion between the grinding wheel 10 and the inner wall of the pipe to be polished, which is more conducive to improving the grinding effect and grinding accuracy. At the same time, the structure can The grinding device has self-adaptive ability, without manual adjustment,...

Embodiment 3

[0041] Compared with embodiment 1, the difference of embodiment 3 is that the number of rotating grinding parts 2 is set to four, that is, the four rotating grinding parts 2 are evenly distributed on the circumference with the central axis of the driving bevel gear 6 as the axis, The four rotating grinding parts 2 simultaneously grind the inner wall of the pipe fitting to be polished. At this time, a transmission motor with a higher rotational speed can be used to increase the speed of the grinding device during the grinding process without affecting the grinding effect, and the efficiency is higher.

[0042] In the specific use process of the present invention, after the pipe to be polished is fixed on the workbench, the grinding device is set in cooperation with the pipe to be polished, and the motor control device is used to control the speed of the driving motor 5 to control the grinding accuracy. Control the drive motor, thereby controlling the speed of the axial feed move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com