High-speed laser cladding and turning integrated machine device

A laser cladding, all-in-one technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems affecting the uniformity of coating thickness and the quality of the cladding layer, so as to reduce workstations and processes and improve product quality , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

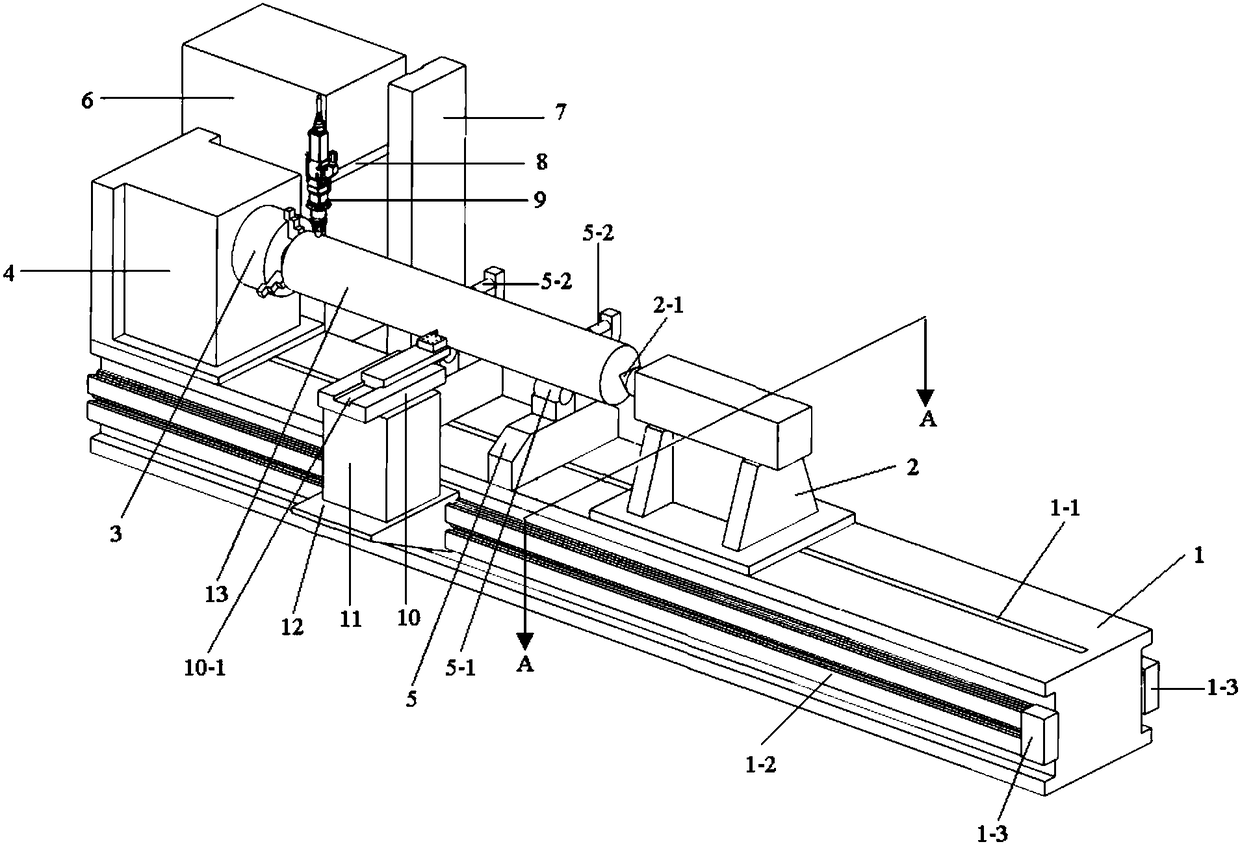

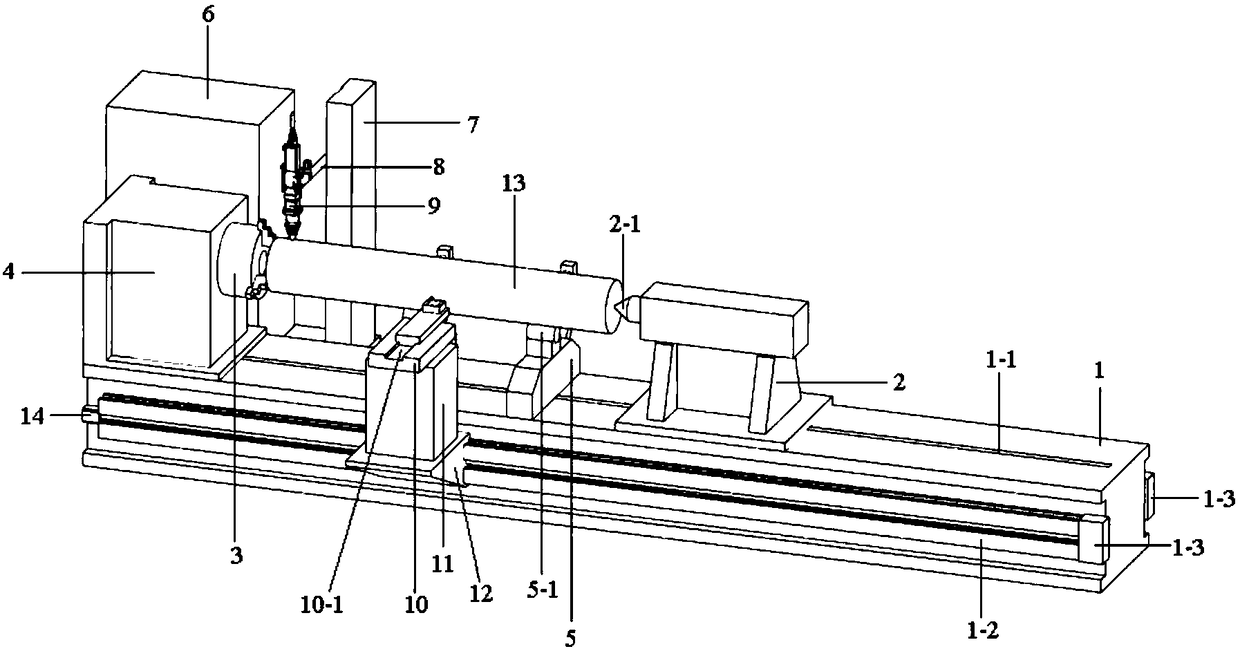

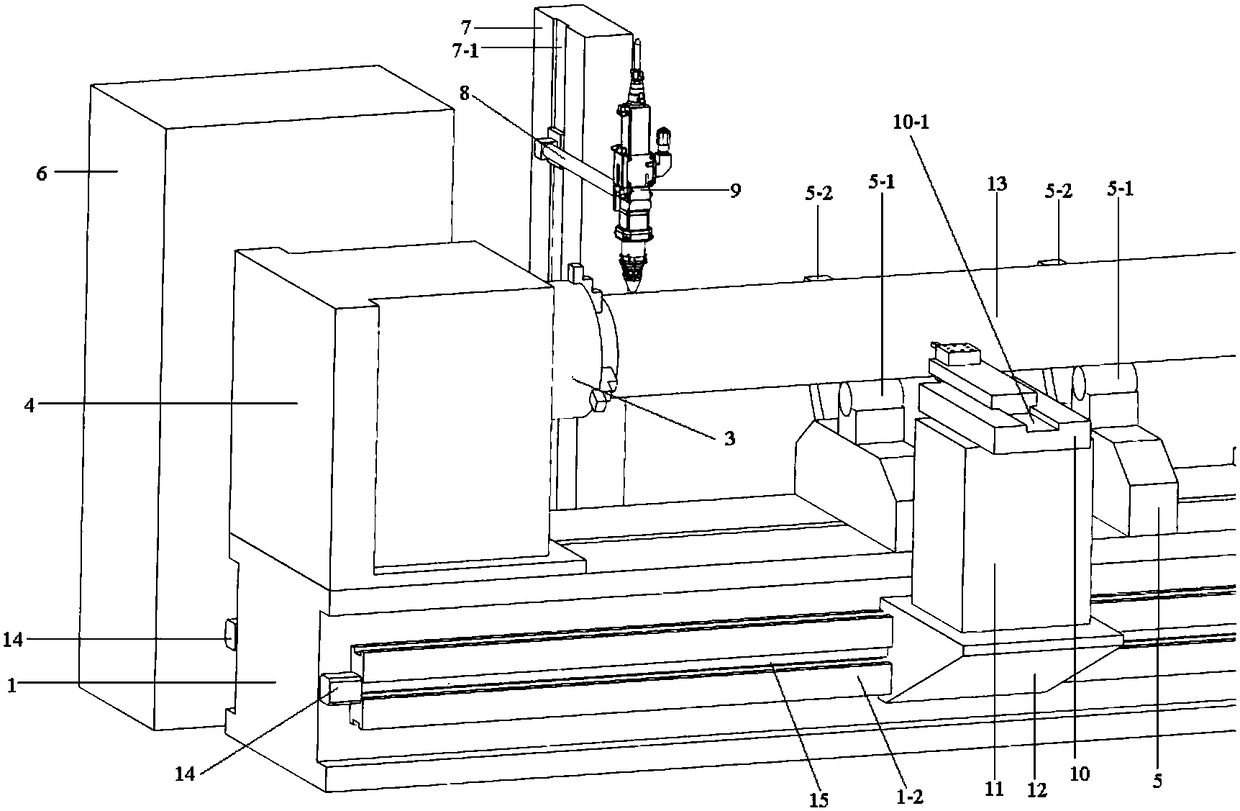

[0028] Specific implementation mode 1: This implementation mode is a high-speed laser cladding and turning composite integrated machine device, such as Figure 1-Figure 9 As shown, it is specifically composed of machine tool 1, tailstock 2, three-jaw chuck 3, headstock 4, support seat 5, control box 6, laser head fixed body 7, telescopic rod 8, laser head 9, turning tool holder 10, Turning tool holder base 11, turning tool holder sliding table 12, motor 14, first ball screw 15, second ball screw 16, third ball screw 17 and laser head fixed body sliding table 18;

[0029] The center of the upper end surface of the machine tool 1 is provided with a through groove 1-1, and the described through groove 1-1 penetrates the upper end surface of the machine tool 1, and the first slideway 1-2 and the second slideway 1-2 are respectively arranged on the two sides of the machine tool 1. Two slideways 1-4, the through groove 1-1, the first slideway 1-2 and the second slideway 1-4 are para...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the motor 14 is a servo motor. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the turning tool holder 10 is a four-station turning tool holder. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com