Stamping and spinning integrated forming device for thin-wall cylinder part with concave bottom and forming method thereof

A technology of thin-walled tube and punching, which is applied in the field of punching and spinning integrated forming device for thin-walled tube with concave bottom, which can solve the problem of difficult to ensure the tightness of thin-walled weld seams, high requirements for workers' welding technology, and complicated spinning forming process and other problems, to achieve the effect of reducing the number of molds and tooling, shortening the forming cycle, and reducing the number of forming passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

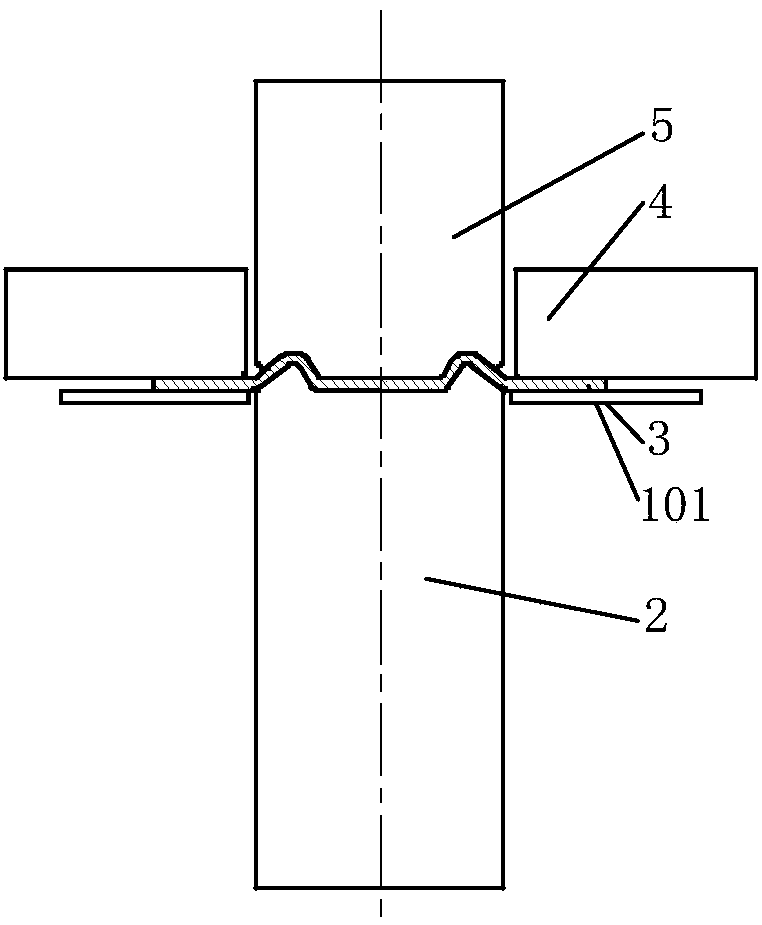

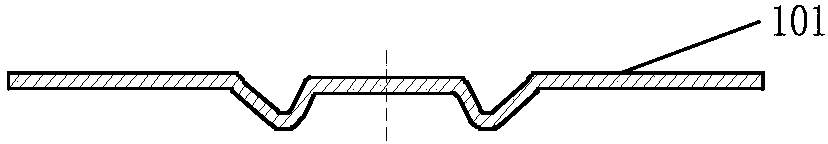

[0029] See attached picture.

[0030] An integrated punching and spinning forming device for thin-walled cylindrical parts with a concave bottom, including upper and lower templates 12, 13, a movable template 14 is arranged above the upper template 12; a cylindrical punch is installed in the lower template 13 for rotation 2. The punch is controlled to rotate by the hydraulic motor 11. The top surface of the punch 2 is provided with an annular protrusion corresponding to the shape of the bottom of the thin-walled cylinder with a concave bottom. The top of the punch 2 is equipped with a blank holder 3, which 3 and the lower template are provided with a spring 10; the upper template 12 is rotatably equipped with a columnar middle die 5 corresponding to the position of the punch 2, and the bottom surface of the middle die 5 is provided with a ring corresponding to the annular protrusion. Ring-shaped groove, the bottom of the middle die 5 is set with a movable die 4 fixed on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com