Wall structure for fixing external wall composite thermal insulation template and construction method

A composite thermal insulation and wall structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of falling off, difficult to control the flatness, and bulging and cracking at the joints of the thermal insulation board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

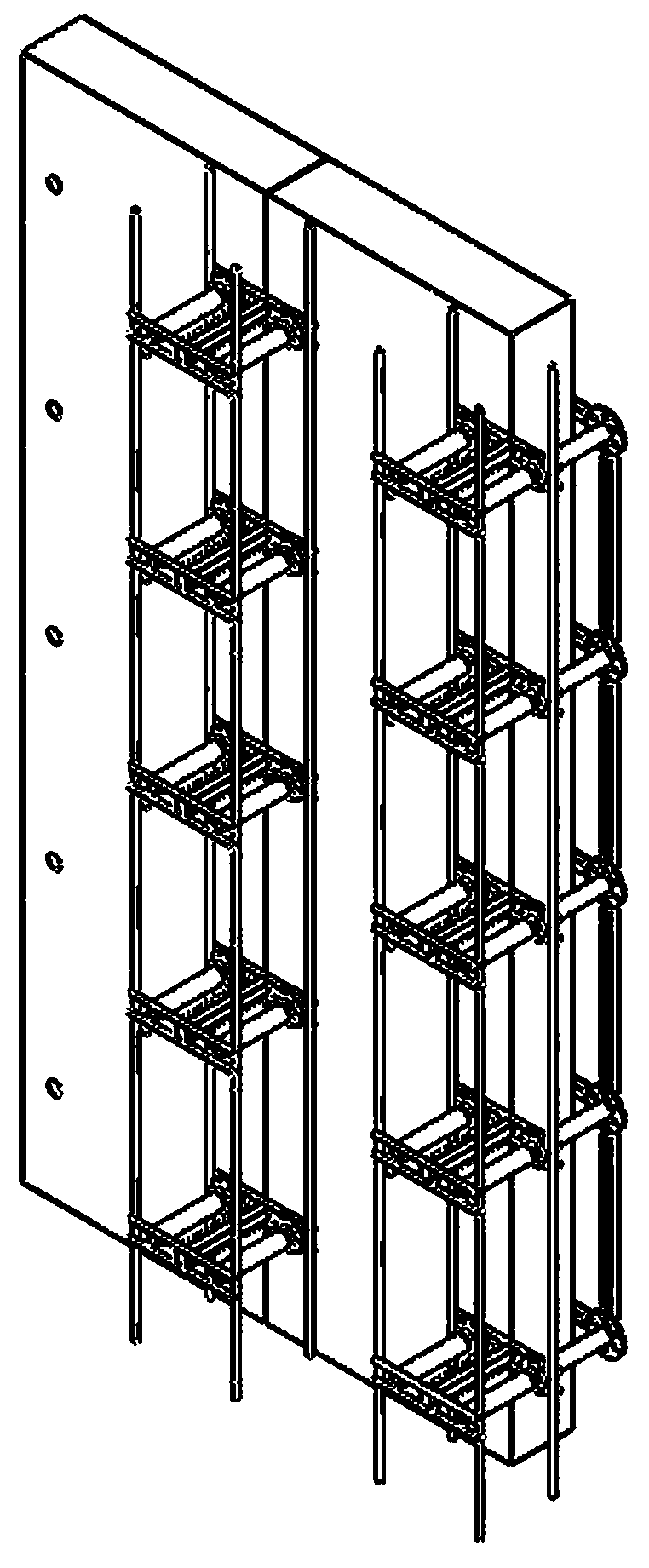

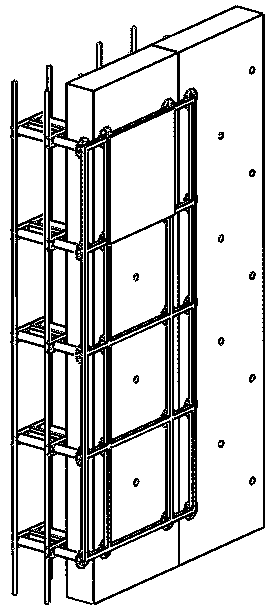

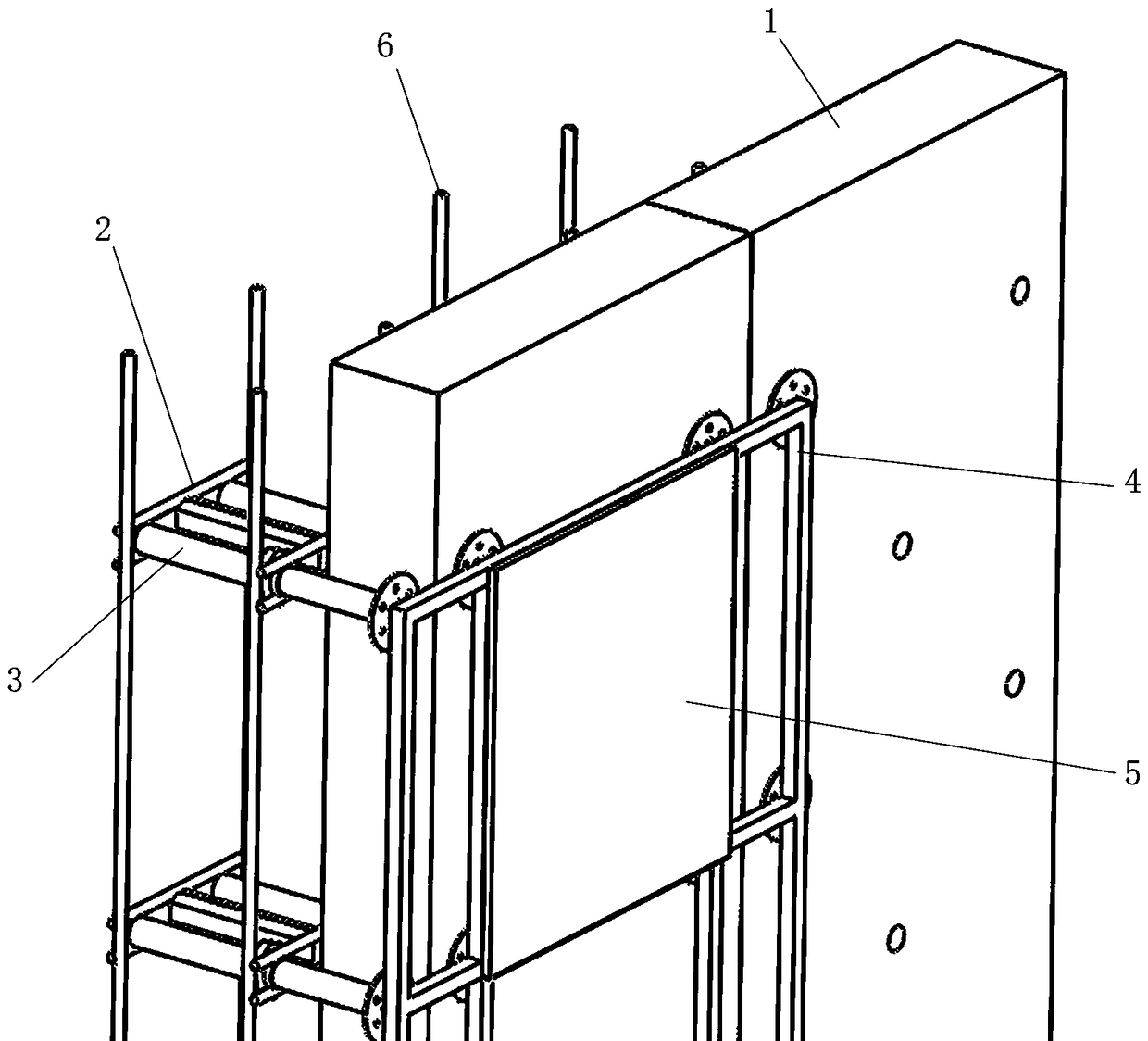

[0042] As shown in the figure, the present invention is the following wall structure:

[0043] The outer side of the structure is a composite thermal insulation formwork 1, and the inner side is a reinforced concrete structure;

[0044] In the reinforced structure of pouring concrete, an I-shaped limiter 2 is erected between the longitudinal steel bars 6; the I-shaped limiter 2 includes a limit column 2-2 and positioning rods 2-1 at both ends of the limit column 2-2, and the positioning The rod 2-1 is located at the head and tail of the limit column 2-2, and two parallel bars are arranged at one end close to the composite thermal insulation formwork 1; the I-shaped limiter is used to accurately limit the thickness of the wall to prevent the formwork from protruding or sagging.

[0045] A nylon rivet 3 is worn in the opening of the composite thermal insulation formwork 1; the nylon rivet 3 passes through the gap between the positioning rods 2-1, and is locked with a nut 7, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com