Highly-oriented two-dimensional hybrid perovskite thin film regulated and controlled by substrate and preparation method thereof

A high-orientation, perovskite technology, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problem of disordered film grains, and achieve the effect of low raw material, simple preparation method and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

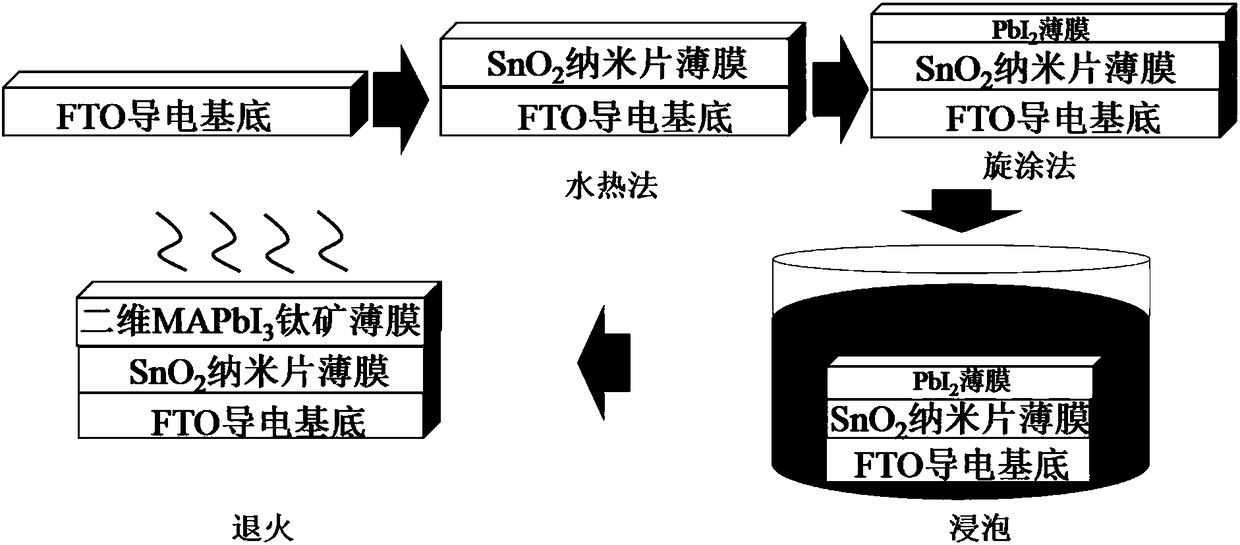

[0024] Such as figure 1 As shown, a method for preparing a highly oriented two-dimensional hybrid perovskite film regulated by a substrate includes the following steps:

[0025] (1) Pretreatment: Select FTO with a sheet resistance of 10Ω and a transmittance of 90% as the conductive glass substrate material, then use ethanol, isopropanol, acetone, and ethanol to ultrasonically clean for 20 minutes, and then use N 2 blow dry.

[0026] (2) Preparation of SnO 2 Nanosheet film: put the washed and dried FTO substrate into SnCl with a concentration of 5mmol / L 2 In the aqueous solution, react in a pressurized and airtight environment for 5h, and the reaction temperature is 150°C. After the reaction, take out the SnO 2 Nanosheet thin film samples were rinsed with deionized water and ethanol in turn, and rinsed with N 2 Blow dry, after N 2 After drying, the SnO 2 The nanosheet film samples were dried at 100°C for 20 minutes, and then left to cool to room temperature for later use ...

Embodiment 2

[0031] A method for preparing a highly oriented two-dimensional hybrid perovskite film regulated by a substrate, comprising the following steps:

[0032] (1) Pretreatment: Select ITO with a sheet resistance of 12Ω and a transmittance of 90% as the conductive glass substrate material, and then use ethanol, isopropanol, acetone, and ethanol to ultrasonically clean for 20 minutes, and then use N 2 blow dry.

[0033] (2) Preparation of SnO 2 Nanosheet film: put the cleaned and dried ITO substrate into SnCl with a concentration of 11.25mmol / L 2 In the aqueous solution, react in a pressurized and airtight environment for 6h, and the reaction temperature is 180°C. After the reaction, take out the SnO 2 Nanosheet thin film samples were rinsed with deionized water and ethanol in turn, and rinsed with N 2 Blow dry, after N 2 After drying, the SnO 2 The nanosheet thin film samples were dried at 100°C for 20 minutes, and then left to cool to room temperature for later use to prepare ...

Embodiment 3

[0038] A method for preparing a highly oriented two-dimensional hybrid perovskite film regulated by a substrate, comprising the following steps:

[0039] (1) Pretreatment: Select FTO with a sheet resistance of 15Ω and a transmittance of 90% as the conductive glass substrate material, then use ethanol, isopropanol, acetone, and ethanol to ultrasonically clean for 20 minutes, and then use N 2 blow dry.

[0040] (2) Preparation of SnO 2 Nanosheet film: put the washed and dried FTO substrate into SnCl with a concentration of 15mmol / L 2 In the aqueous solution, react in a pressurized and airtight environment for 8h, and the reaction temperature is 200°C. After the reaction, take out the SnO 2 Nanosheet thin film samples were rinsed with deionized water and ethanol in turn, and rinsed with N 2 Blow dry, after N 2 After drying, the SnO 2 The nanosheet thin film samples were dried at 100°C for 20 minutes, and then left to cool to room temperature for later use to prepare SnO with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com