Pressure control system

A technology of pressure control and hydraulic cylinder, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc. It can solve the problems that the ball cannot be accurately aligned with the valve seat, the degree of firmness is not enough, and the function is single, so as to achieve convenience in daily life. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

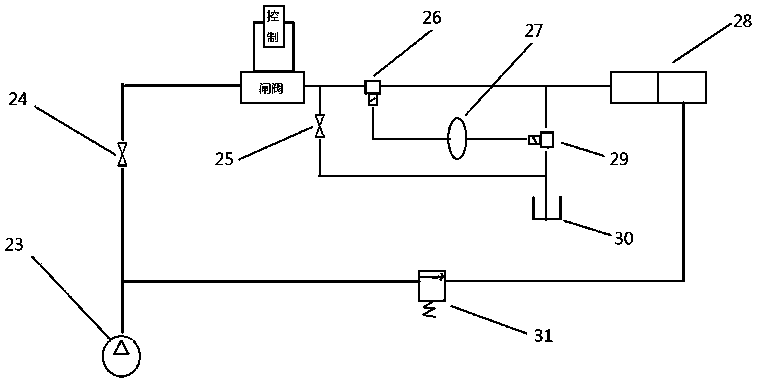

[0037] As shown in the figure: a pressure control system, the pressure control system includes a pump, a first switch, a second switch, a first three-way valve, an accumulator, a hydraulic cylinder, a second three-way valve, an oil tank, and a solenoid valve , gate valve; the liquid in the pump is connected to the first chamber of the hydraulic cylinder through the main road, and connected to the second chamber of the hydraulic cylinder through the auxiliary road; the main road includes the first switch, the gate valve, the first tee valve; the auxiliary circuit includes the solenoid valve;

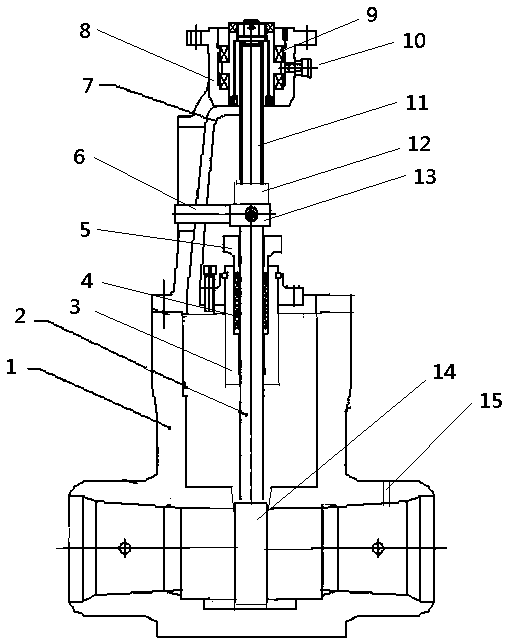

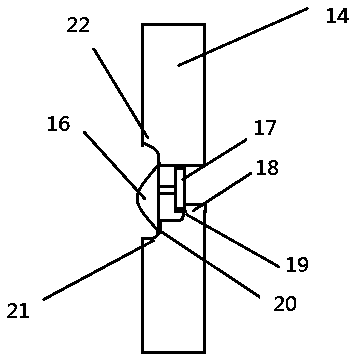

[0038] As shown in the figure: after the liquid is output from the pump, it is connected to the gate valve through the first switch, and the gate valve includes a valve body, a lower valve stem, a stuffing box, packing, a packing gland, a stem support frame, a bracket, and a flange. Lan, bearing, grease nipple, upper valve stem, support ring, support seat, ram, sampling hole, umbrella win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com