A method for regulating the reinforcement phase of tib-reinforced titanium-based composites

A technology of titanium-based composite material and reinforcing phase, which is applied in the field of enhanced phase regulation of TiB-reinforced titanium-based composite material, can solve problems such as enhanced phase regulation, and achieves improved mechanical properties, widened the scope of preparation and application, and has strong process applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

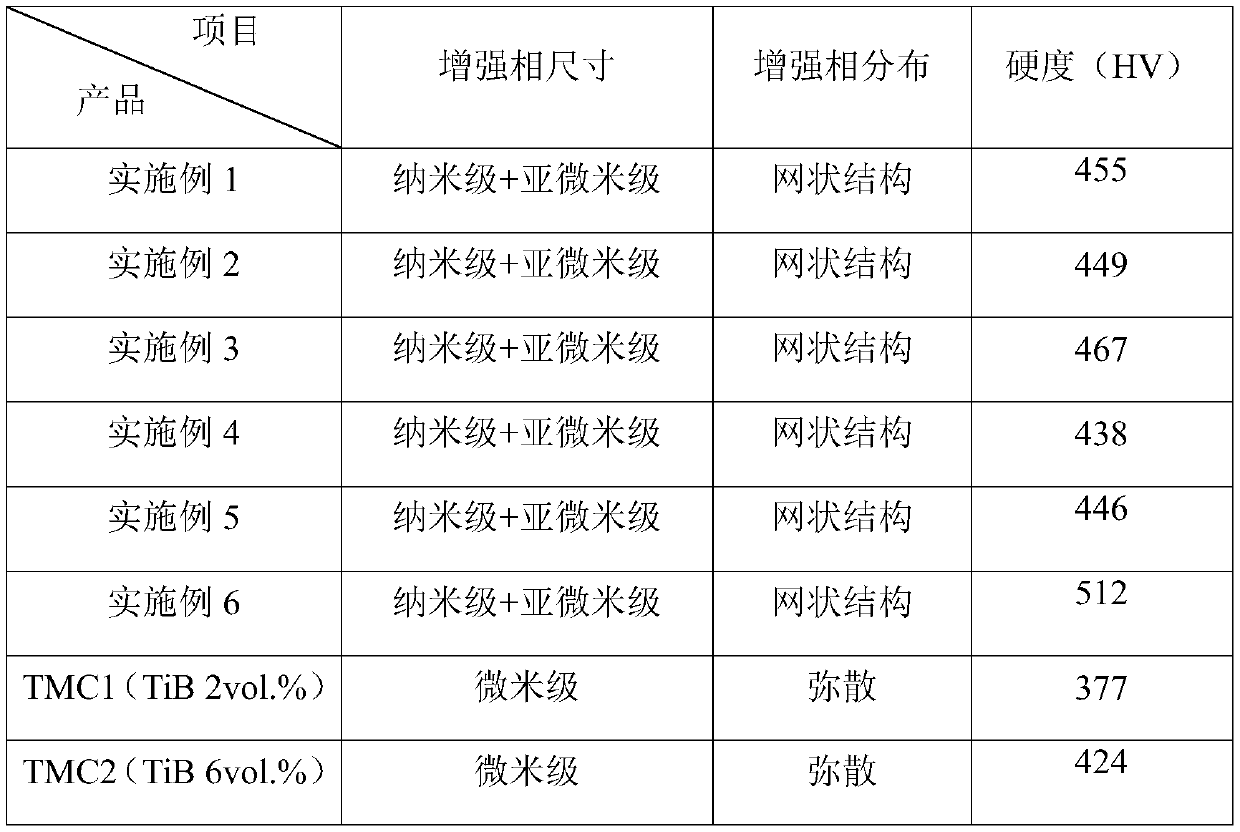

Embodiment 1

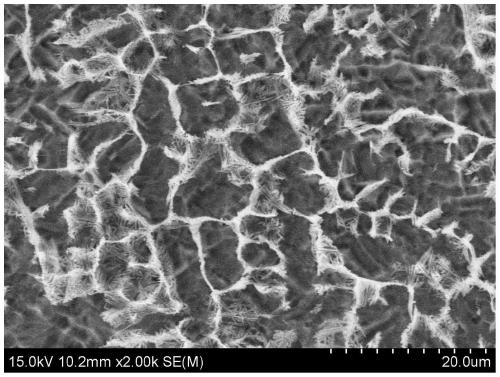

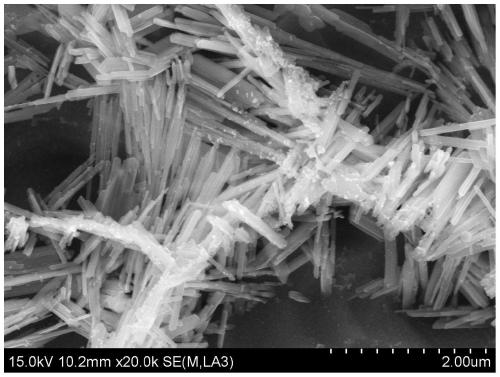

[0021] Using TiB (2vol.%) reinforced titanium-based composite material as the matrix, the TiB-reinforced titanium-based composite material is firstly melted by electron beam technology, in which the current is 9mA, the voltage is 40kV, the scanning speed is 10mm / s, and the heat output is 3.6J / mm . Then, low-temperature aging treatment is carried out on the melted composite material, wherein the aging temperature is 500°C, the holding time is 8h, and it is cooled with the furnace.

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 lies in the electron beam melting treatment, in which the current is 6 mA, the voltage is 60 kV, the scanning speed is 10 mm / s, and the heat output is 3.6 J / mm.

Embodiment 3

[0025] The difference between this embodiment and Embodiment 1 lies in the electron beam melting treatment, wherein the current is 6 mA, the voltage is 50 kV, the scanning speed is 10 mm / s, and the heat output is 3 J / mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com