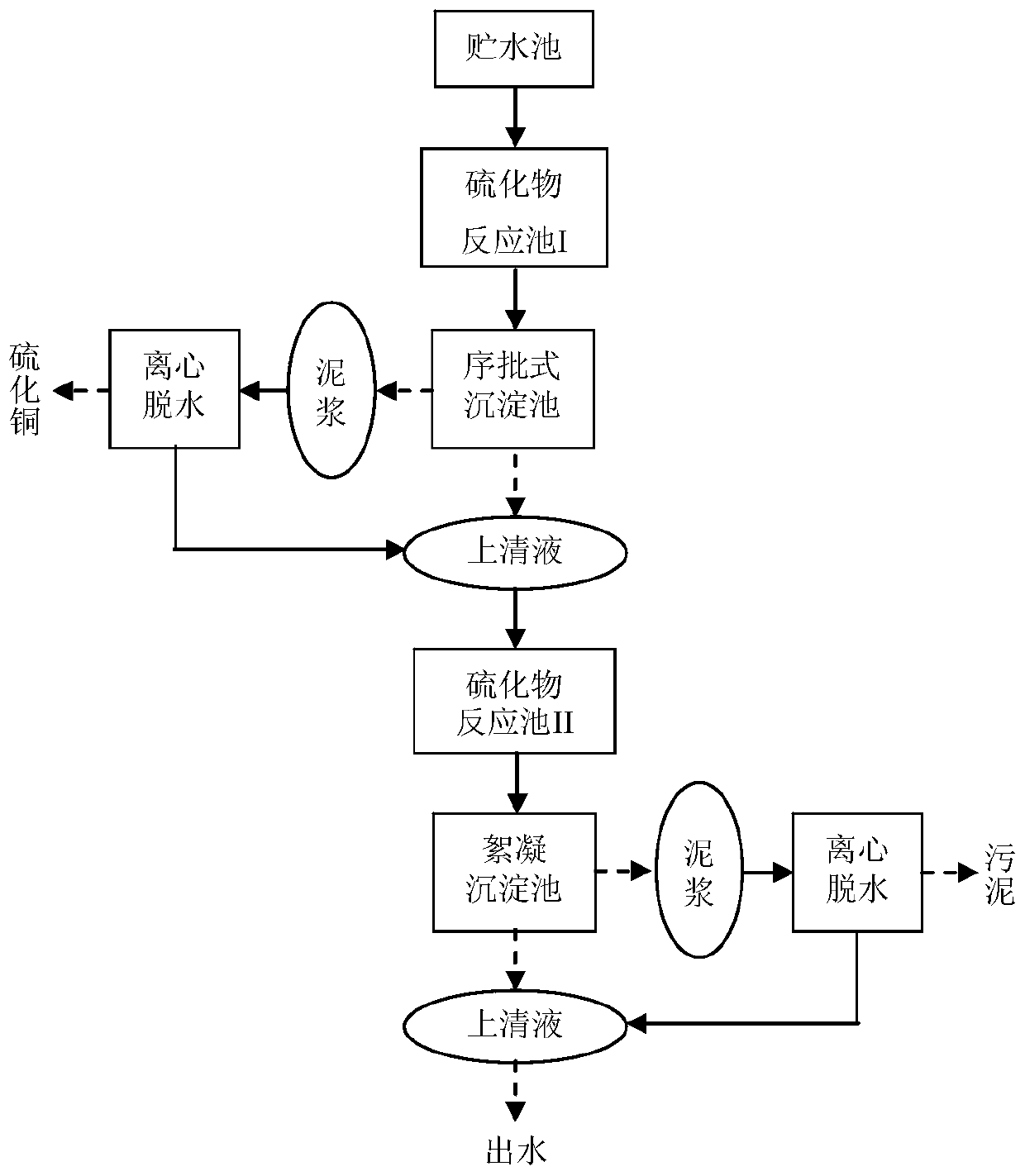

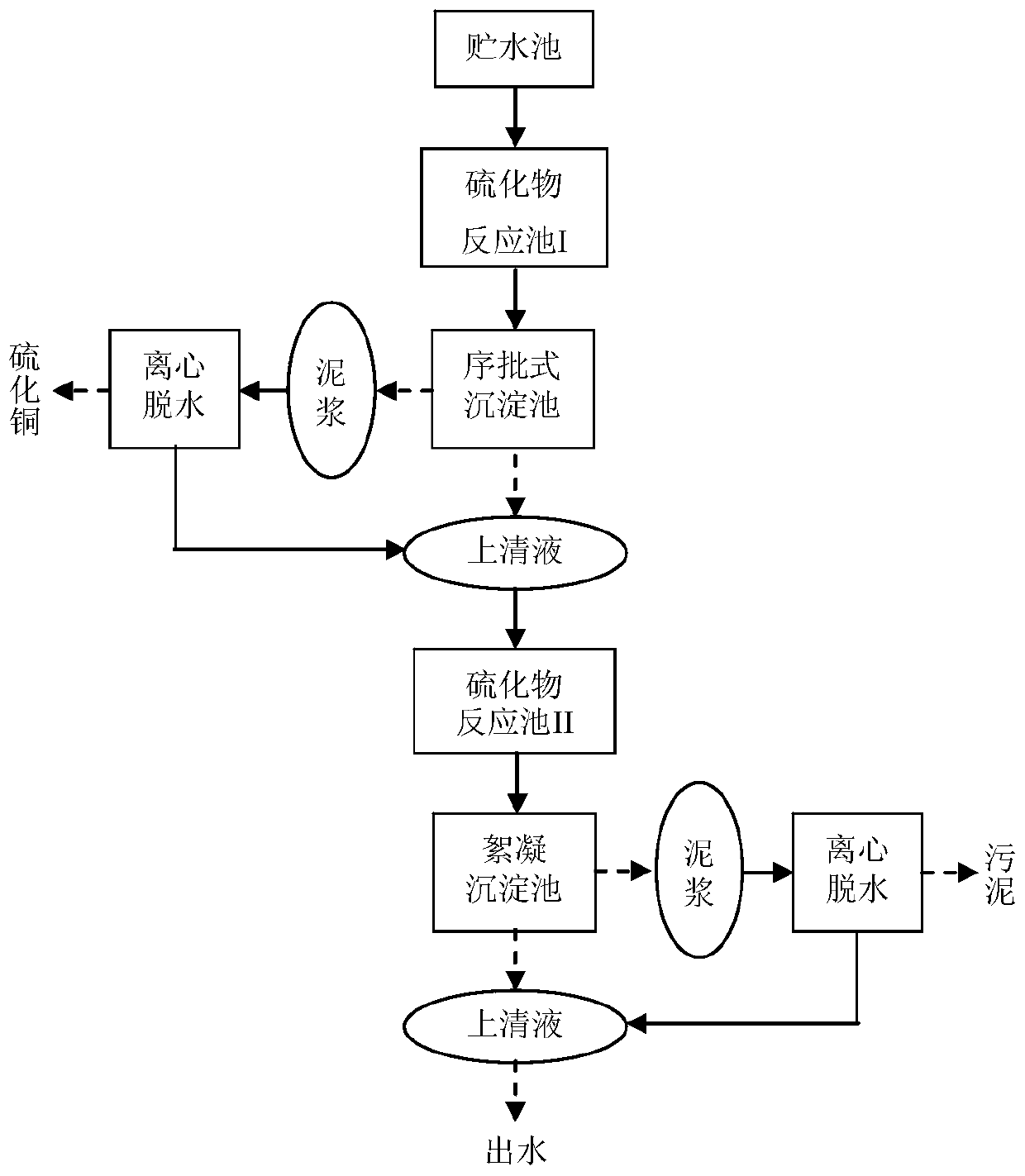

A method for treating copper-containing electroplating wastewater and recovering copper by using sulfide precipitation method

A technology of sulfide precipitation and copper electroplating, applied in the field of environmental engineering, can solve the problems of easy formation of colloids, secondary pollution, and high processing costs, and achieve the effect of avoiding loss and simplifying the operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The electroplating wastewater is taken from an electroplating factory in Shandong, which mainly produces copper-zinc-nickel plating parts. The specific processing steps are as follows:

[0049] (1) The storage tank collects waste water

[0050] The storage tank collects the copper-containing electroplating wastewater discharged from the electroplating workshop, and the initial pH of the wastewater is 1.5; after measurement, the main metal content of the wastewater is: Cu 121mg / L, Zn 64mg / L, Ni 76mg / L, Fe 73mg / L, and other heavy metals All lower than 5mg / L.

[0051] (2) Sulfide Precipitated Copper

[0052] The electroplating wastewater in the water storage tank enters the sulfide reaction tank I, and adding an initial concentration to the reaction tank is a sodium sulfide solution of 0.5mol / L, and the sodium sulfide addition is 95% of the amount of copper in the wastewater; then control the pH value of the system lower than 2.0 and stirred for 10 minutes; after the re...

Embodiment 2

[0057] The electroplating wastewater is taken from an electroplating factory in Jiangsu, which mainly produces copper-plated parts. The specific processing steps are as follows:

[0058] (1) The storage tank collects waste water

[0059] The storage tank collects the copper-containing electroplating wastewater discharged from the electroplating workshop. The initial pH of the wastewater is 3.4, and the pH is adjusted to 3.0. After determination, the main metal content of the wastewater is: Cu 130mg / L, Zn 34mg / L, Ni 9mg / L, Fe 57mg / L, and other heavy metal contents are all lower than 5mg / L.

[0060] (2) Sulfide Precipitated Copper

[0061] The electroplating wastewater in the water storage tank enters the sulfide reaction tank I, and adding an initial concentration in the reaction tank is a sodium sulfide solution of 1.5mol / L, and the sodium sulfide addition is 90% of the amount of copper in the wastewater; then control the pH value of the system lower than 3.5, stirring and ...

Embodiment 3

[0066] The electroplating wastewater is taken from an electroplating factory in Jiangsu, which mainly produces copper-plated parts. The specific processing steps are as follows:

[0067] (1) The storage tank collects waste water

[0068] The storage tank collects the copper-containing electroplating wastewater discharged from the electroplating workshop. The initial pH of the wastewater is 3.4, and the pH is adjusted to 2.0. After determination, the main metal content of the wastewater is: Cu 130mg / L, Zn 34mg / L, Ni 9mg / L, Fe 57mg / L, and other heavy metal contents are all lower than 5mg / L.

[0069] (2) Sulfide Precipitated Copper

[0070] The electroplating wastewater in the storage tank enters the sulfide reaction tank I, and the sodium sulfide solution with an initial concentration of 1.0mol / L is added to the reaction tank, and the sodium sulfide addition is 80% of the amount of copper in the wastewater. Then control the pH value of the system to be lower than 3.0, stir an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com