Method for prolonging cycle life of zinc battery and application thereof

A technology of cycle life and zinc battery, which is applied to a porous coating for inhibiting the growth of zinc dendrites/protrusions and its preparation, is applied in the field of long-life zinc battery, and can solve the problems of high cost, long preparation time, self-corrosion and the like, Achieve the effect of increasing cycle life, reducing energy density and power density, and major economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

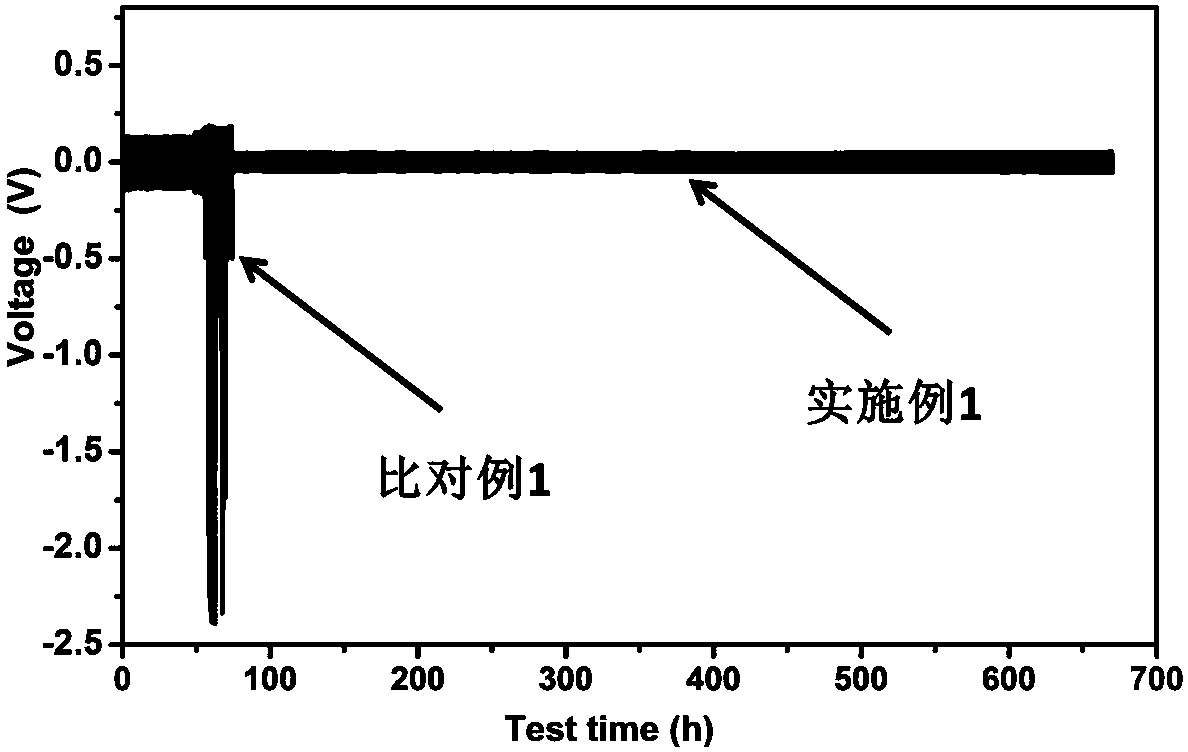

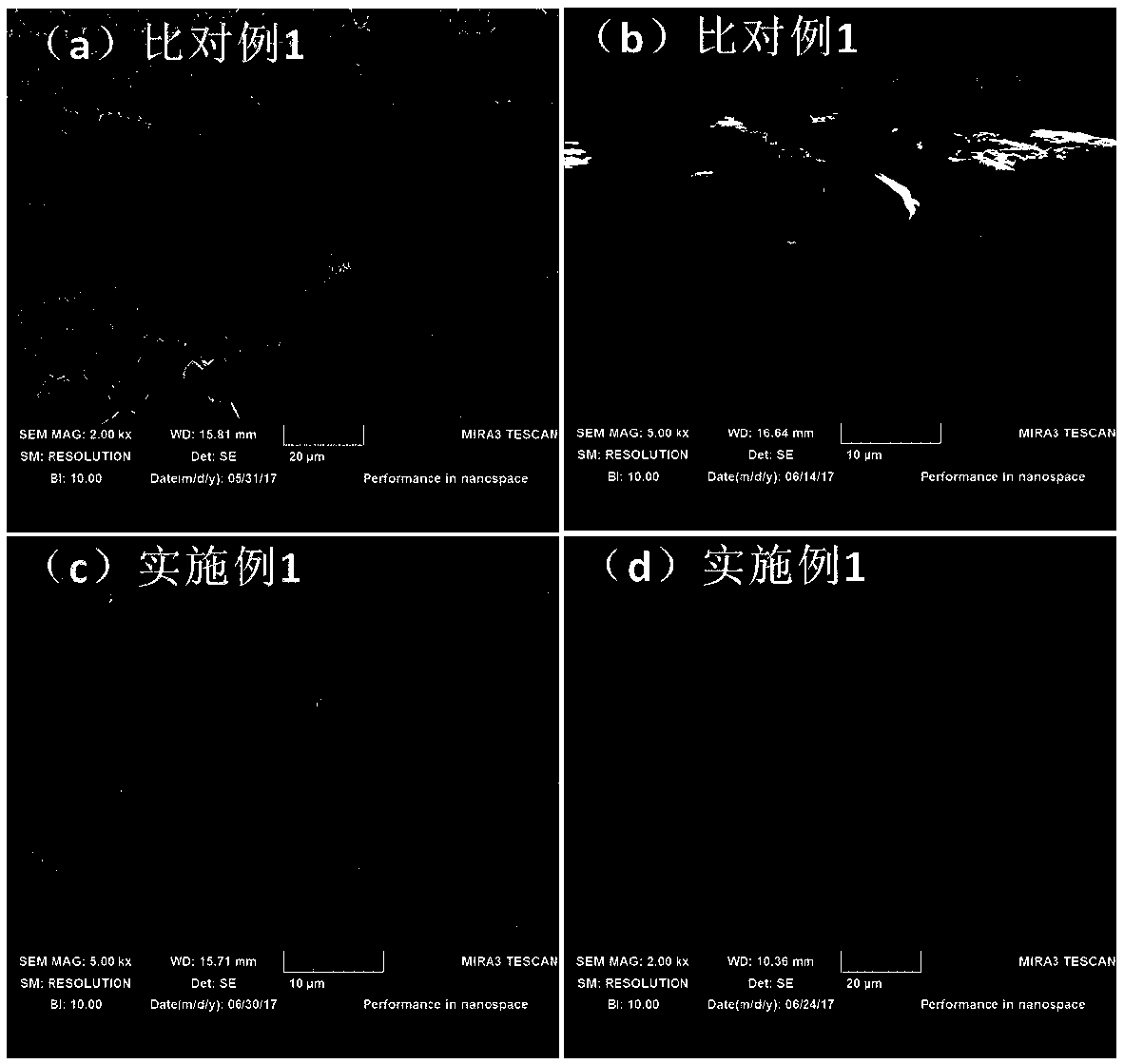

[0041] Weigh 0.360 g nanometer zirconia (ZrO 2 , 10 nm) and 0.040 g PVDF binder, mix them in a mortar and mix well, then pour into a weighing bottle, add NMP solvent, stir magnetically for 4 h at room temperature, after the slurry is evenly stirred, select Apply a film applicator with a suitable thickness, evenly coat a porous coating with a thickness of 230-300 microns on the surface of the pre-cleaned zinc foil, and dry it in vacuum at 60°C for 12 hours. The dried porous ZrO 2 Coated zinc foil cut into Φ = 16 mm discs, and then assembled symmetrical cells to test related electrochemical performances. The electrolyte uses 0.5 M ZnSO 4 Solution, battery separator using filter paper. Its technical effect is as Figure 1-2 shown.

Embodiment 2

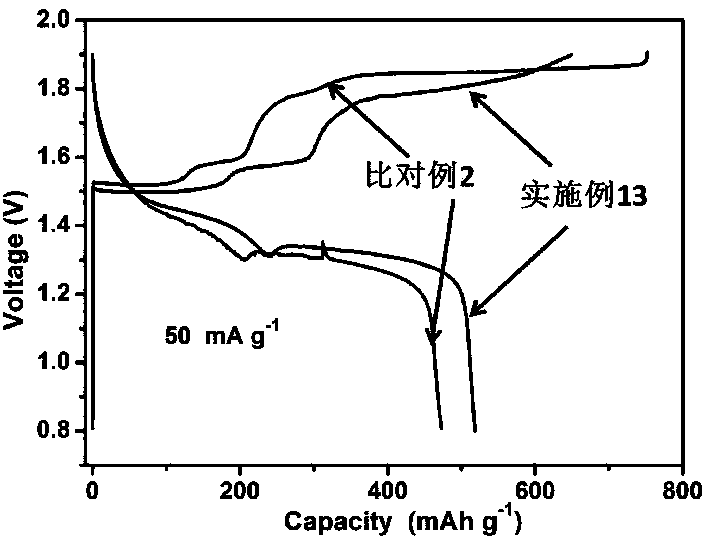

[0043] Weigh 0.180 g of nano-alumina (Al 2 o 3 , 100 nm) and 0.030 g PVDF binder, mix them in a mortar and mix evenly, then pour into a weighing bottle, add NMP solvent, and stir magnetically for 4 h at room temperature. After the slurry is evenly stirred, select A film applicator with a suitable thickness is used to uniformly coat a porous coating with a thickness of 230-300 microns on the surface of the filter paper, and dry it in vacuum at 60 °C for 12 hours. Porous Al 2 o 3 The coated filter paper is the diaphragm, Φ = The 16 mm pre-cleaned zinc foil was used as the positive and negative electrodes, and a symmetrical battery was assembled to test the relevant electrochemical performance. The electrolyte uses 3 M ZnSO 4 + 0.1 M MnSO 4 solution, the battery separator is made of non-woven fabric. Compared with uncoated symmetric cells, the coating can increase the stability time of symmetric cells from 56 hours to 410 hours.

Embodiment 3

[0045] Weigh 0.010 g micron calcium carbonate (CaCO 3 , 2000 nm) and 0.080 g PVDF binder, mix them in a mortar and mix evenly, then pour into a weighing bottle, add NMP solvent, stir magnetically at room temperature for 2 h, after the slurry is evenly stirred, select Apply a film applicator with a suitable thickness, evenly coat a porous coating with a thickness of 230-300 microns on the surface of the pre-cleaned zinc foil, and dry it in vacuum at 60°C for 12 hours. Dry porous CaCO 3 Coated zinc foil cut into Φ = 16 mm discs, and then assembled symmetrical cells to test related electrochemical performances. The electrolyte uses 1.5 M ZnSO 4 Solution, battery separator using filter paper. The coating can increase the stability time of symmetric cells from 45 hours to 367 hours relative to uncoated symmetric cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com