Low-friction drag composite nano-proppant and preparation method thereof

A proppant and low-friction technology, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problem that proppant cannot reduce friction, fracturing fluid has high friction, and fracturing effect is not good. Good and other problems, to achieve good suspension, reduce friction, reduce the effect of equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

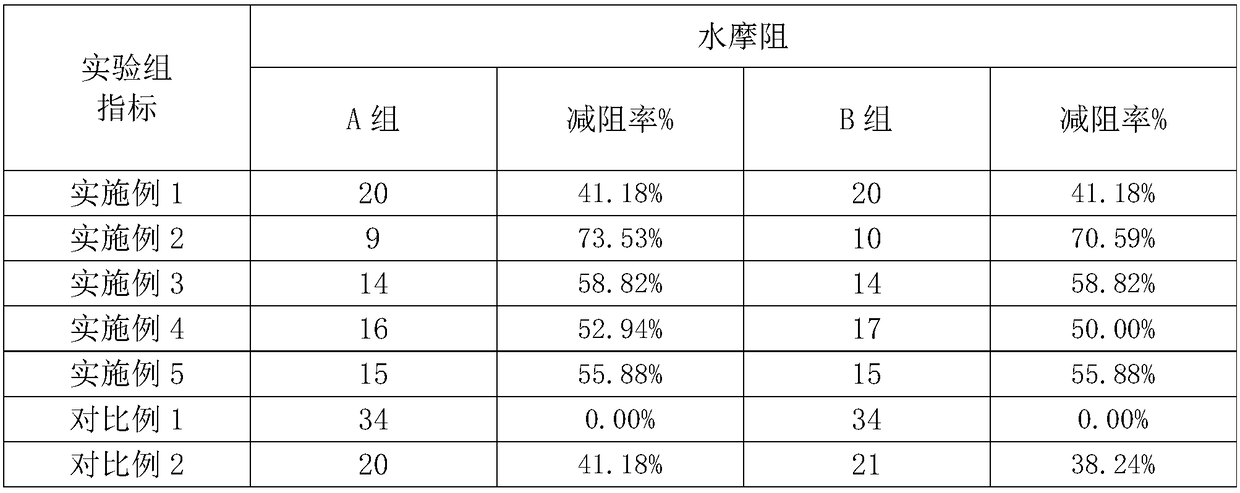

Examples

Embodiment 1

[0034] This embodiment discloses a method for preparing a low-friction composite nano-proppant, which includes the following steps:

[0035] (1) taking styrene derivatives and / or acrylic acid derivatives, and divinylbenzene as comonomers, adding modified nano-fillers, and forming high-molecular polymers through suspension polymerization to obtain composite nano-aggregates;

[0036] Styrene derivatives include one or more of styrene, methylstyrene, ethylstyrene, and dimethylstyrene;

[0037] Acrylic acid derivatives include methyl acrylate, ethyl acrylate, butyl acrylate, hexyl acrylate, octadecyl acrylate, methyl methacrylate, ethyl methacrylate, butyl methacrylate, hexyl methacrylate, methyl One or more of octadecyl acrylate, methoxypolyethylene glycol methacrylate, methacrylic acid, and allyl methacrylate;

[0038] Modified nanofillers include surfactants, silane coupling agents, titanate coupling agents, cellulose modification, glass fiber, silicon titanium iron aluminum c...

Embodiment 2

[0050] The difference between Example 2 and Example 1 is that in step (4), the polyacrylamide is anionic polyacrylamide with a content of 0.2%; the drag reducer content is 1%, and the surfactant content is 0.5%.

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is: in step (4), polyacrylamide is selected anionic polyacrylamide for use, and its content is 0.1%; Drag reducer content is 0.8%; Surfactant is selected benzyl chloride for use, and its content 0.08%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com