Preparing method of eight-pod ZnO nanopowder

A nano powder, foot body technology, applied in the field of nano materials, to achieve the effect of low cost, rough surface and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A kind of preparation method of octapod ZnO nanopowder of the present invention, specifically implement according to the following steps:

[0018] Step 1, prepare the N-N dimethylformamide (DMF) solution of anhydrous zinc acetate:

[0019] Use DMF as a solvent to prepare anhydrous zinc acetate solution so that the molar concentration is 0.001-0.1mol / L, and heat the above solution to 60-150°C under magnetic stirring, and record it as solution A;

[0020] Step 2, adding pure water to solution A, the volume ratio of pure water to DMF in step 1 is 1:1-600, and the holding time is 5-90min, and a solid-liquid mixture containing white ZnO precipitate is obtained;

[0021] Step 3, the solid-liquid mixture containing ZnO precipitation obtained in step 2 is centrifuged and washed with absolute ethanol for 3 to 5 times, and then the product after centrifuged washing is dried at 50 to 80°C for 6 to 12 hours to obtain nano ZnO powder.

[0022] The nano-ZnO powder prepared by the m...

Embodiment 1

[0024] Step 1, prepare 30mL of 0.001mol / L anhydrous zinc acetate DMF solution, and then use ultrasonic vibration to obtain a clear and transparent solution, and heat the prepared anhydrous zinc acetate solution to 75°C under magnetic stirring conditions, and record it as solution A ;

[0025] Step 2, add 0.1 mL of pure water to the solution A obtained in step 1, and keep it for 5 minutes to obtain a solid-liquid mixture containing white ZnO precipitate;

[0026] Step 3, the solid-liquid mixture containing ZnO precipitates obtained in step 2 was only centrifuged and washed 5 times with absolute ethanol, and finally the product after centrifuged washing was dried at 80°C for 6 hours to obtain many fine nanoparticles as the basic structural unit The composed three-dimensional hierarchical ZnO nanopowders with octapod morphology.

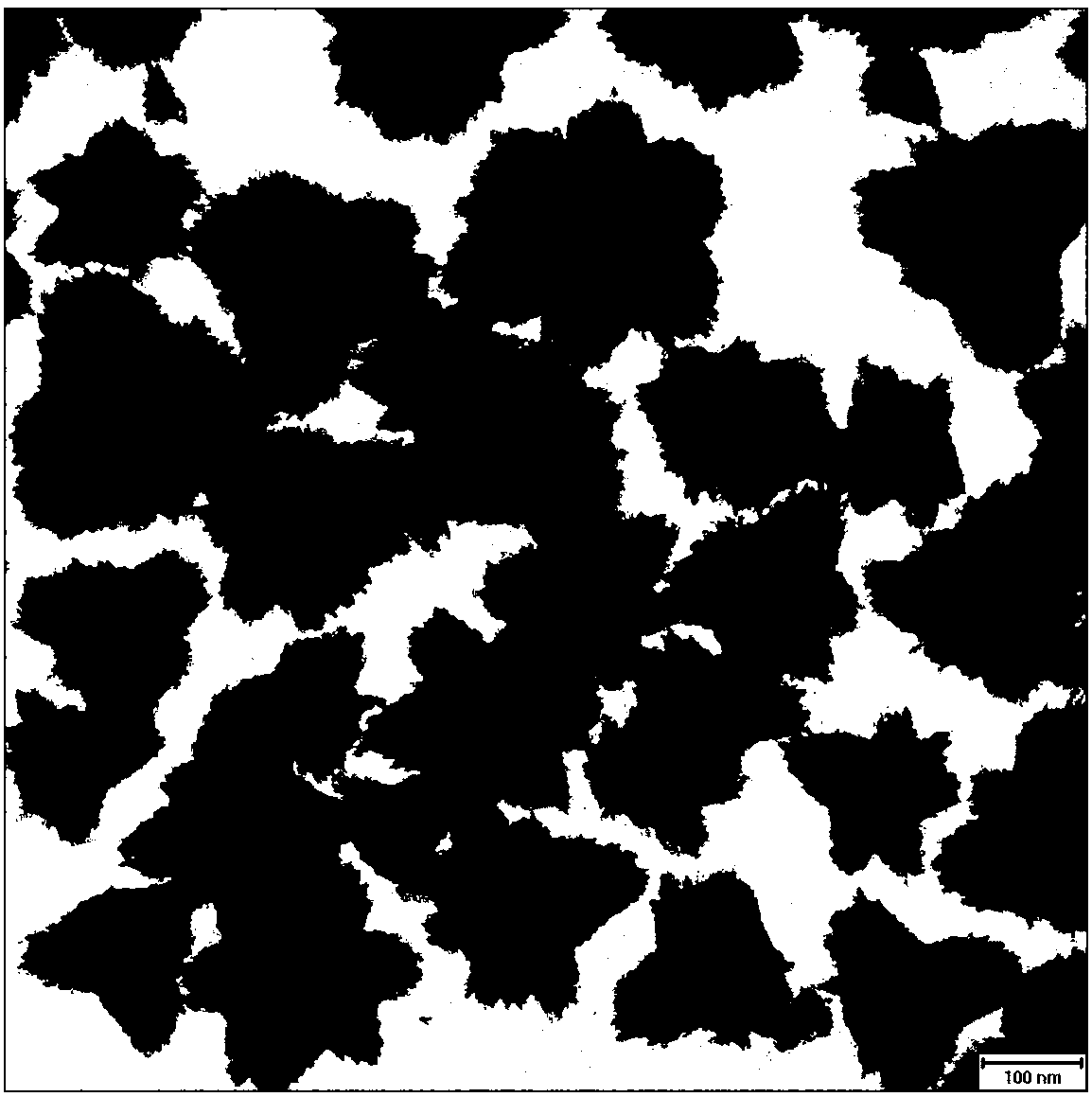

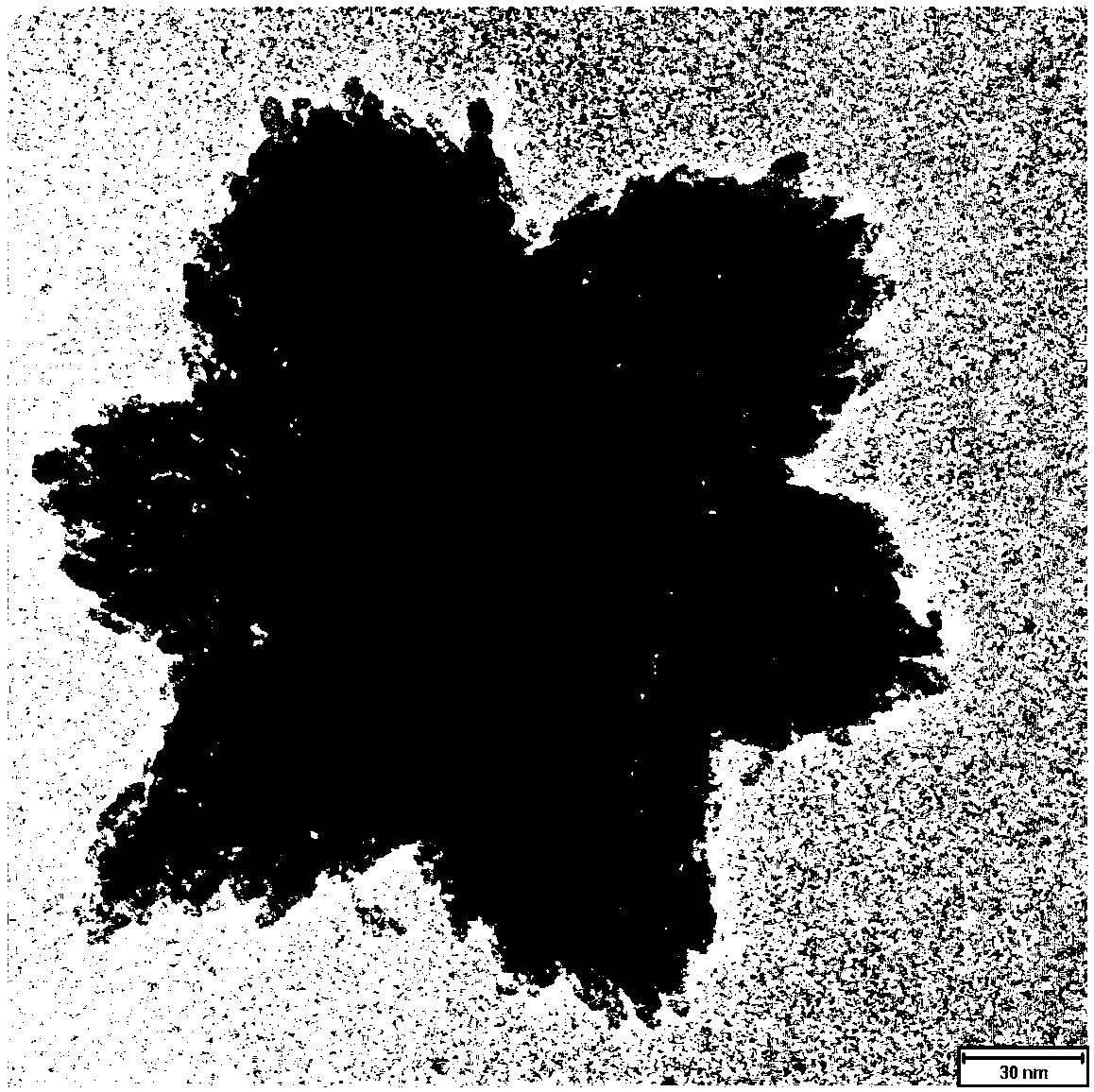

[0027] The transmission electron micrograph of the ZnO nanopowder that present embodiment obtains is as follows figure 1 As shown, it can be seen fro...

Embodiment 2

[0029] Step 1, prepare 30mL of 0.1mol / L anhydrous zinc acetate DMF solution, and then use ultrasonic vibration to obtain a clear and transparent solution, and heat the prepared anhydrous zinc acetate solution to 150°C under magnetic stirring conditions, and record it as solution A ;

[0030] Step 2, add 30mL of pure water to the solution A obtained in step 1, and keep it for 90 minutes to obtain a solid-liquid mixture containing white ZnO precipitate;

[0031] Step 3, the solid-liquid mixture containing ZnO precipitates obtained in step 2 is only centrifuged and washed 3 times with absolute ethanol, and finally the product after centrifuged washing is dried at 80 ° C for 12 hours to obtain many small nanoparticles as the basic structural unit The composed three-dimensional hierarchical ZnO nanopowders with octapod morphology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com