Titanium alloy surface wear-resistant compound ceramic coating and preparation method thereof

A composite ceramic and titanium alloy technology, applied in metal material coating process, coating and other directions, can solve the problem of insufficient wear resistance of the coating, and achieve the effects of uniform mechanical properties, good macro quality and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

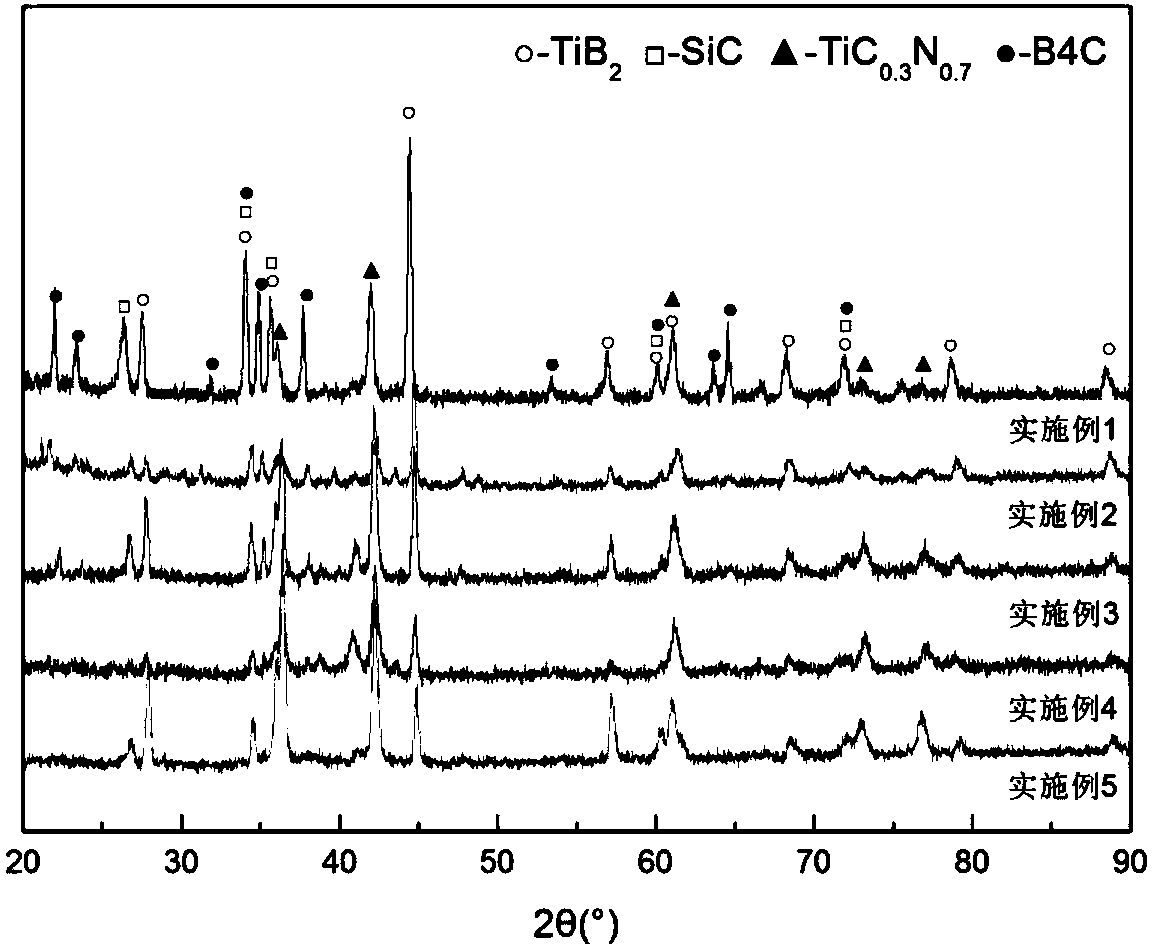

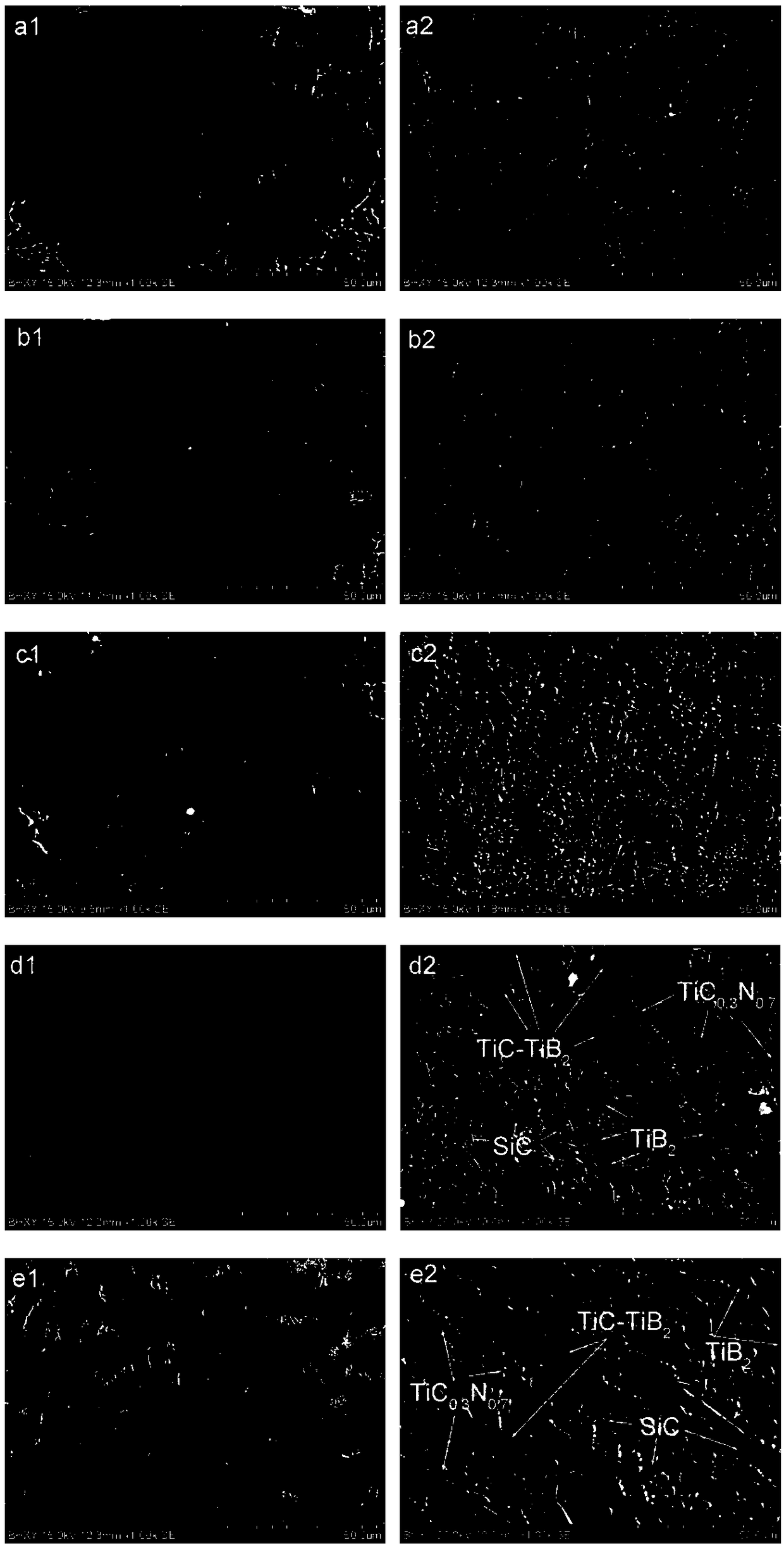

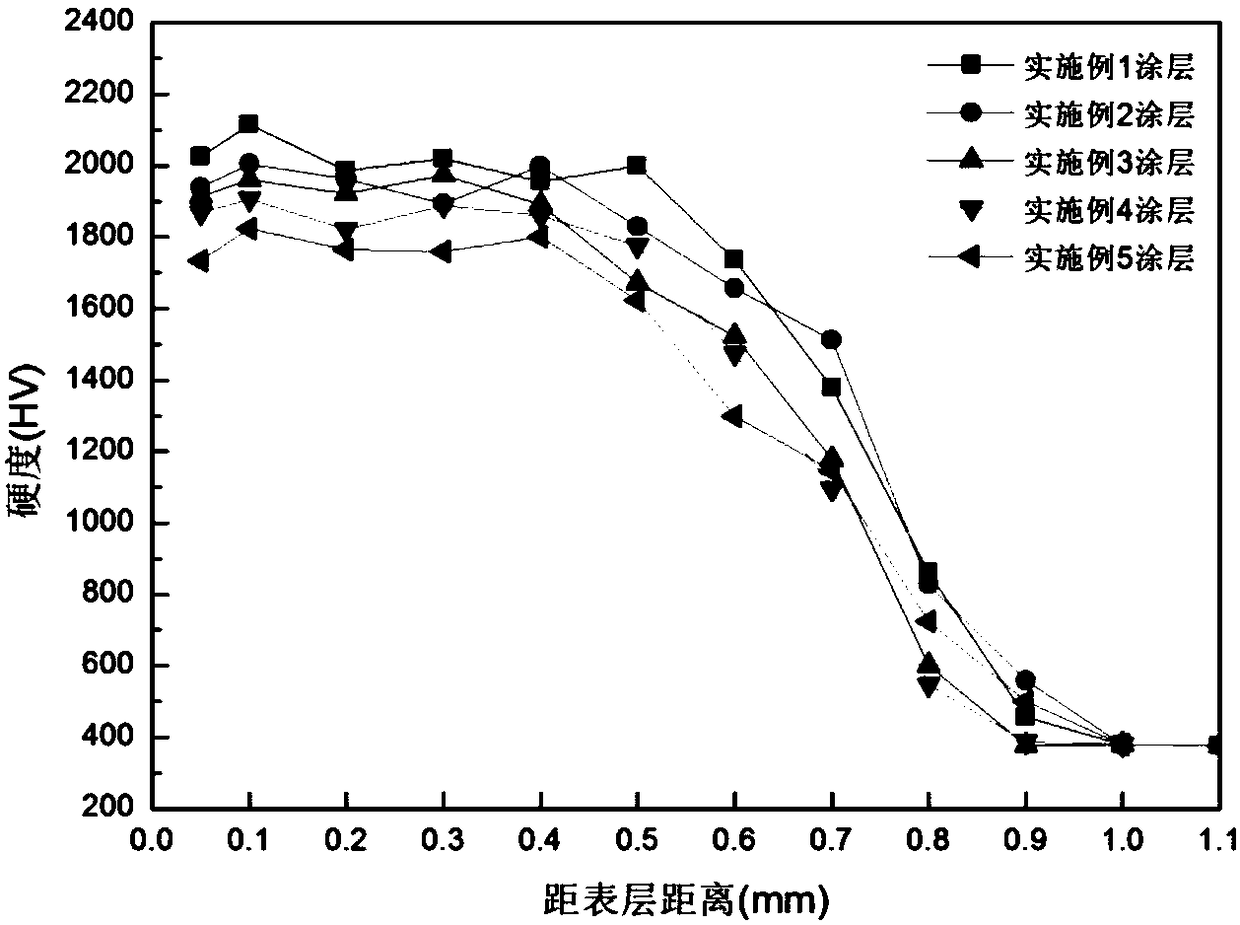

Examples

Embodiment 1

[0051] A method for preparing a wear-resistant composite ceramic coating on a titanium alloy surface, comprising the following steps:

[0052] (1) Preparation and pretreatment of matrix materials

[0053] In this test, Ti-6Al-4V titanium alloy is selected as the coating substrate, and the main components of the substrate are:

[0054] Table 1 Chemical composition of Ti-6Al-4V titanium alloy (mass fraction, %)

[0055]

[0056] The sample was cut into strips of 100×10×10mm, polished on 400#, 600# and 1000# sandpaper before the experiment, then cleaned with alcohol and supplemented by ultrasonic vibration, and dried for later use.

[0057] (2) Coating original alloying powder and proportion: 80% B 4 C-10%G-10%Si 3 N 4 (mass fraction), and the powder is mixed evenly with a ball mill for later use.

[0058] (3) Presetting the powder in step (2) on the surface of the alloy in step (1), with a preset thickness of 0.8-1.0mm. Place the pre-powdered sample on a fixed step in a...

Embodiment 2

[0062] Same as Example 1, the difference is: the original alloyed powder of the coating and the proportioning ratio are: 70% B 4 C-10%G-20%Si 3 N 4 (quality score).

Embodiment 3

[0064] Same as Example 1, the difference is: the original alloyed powder of the coating and the proportioning ratio are: 60% B 4 C-20%G-20%Si 3 N 4 (quality score).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com