High-wearing-resistance tungsten alloy powder metallurgy material for precise instrument and preparation method of high-wearing-resistance tungsten alloy powder metallurgy material

A precision instrument and powder metallurgy technology, applied in the field of high wear-resistant tungsten alloy powder metallurgy materials and their preparation, can solve problems such as composition and formula optimization, and achieve the effects of promoting development, reducing production costs, and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

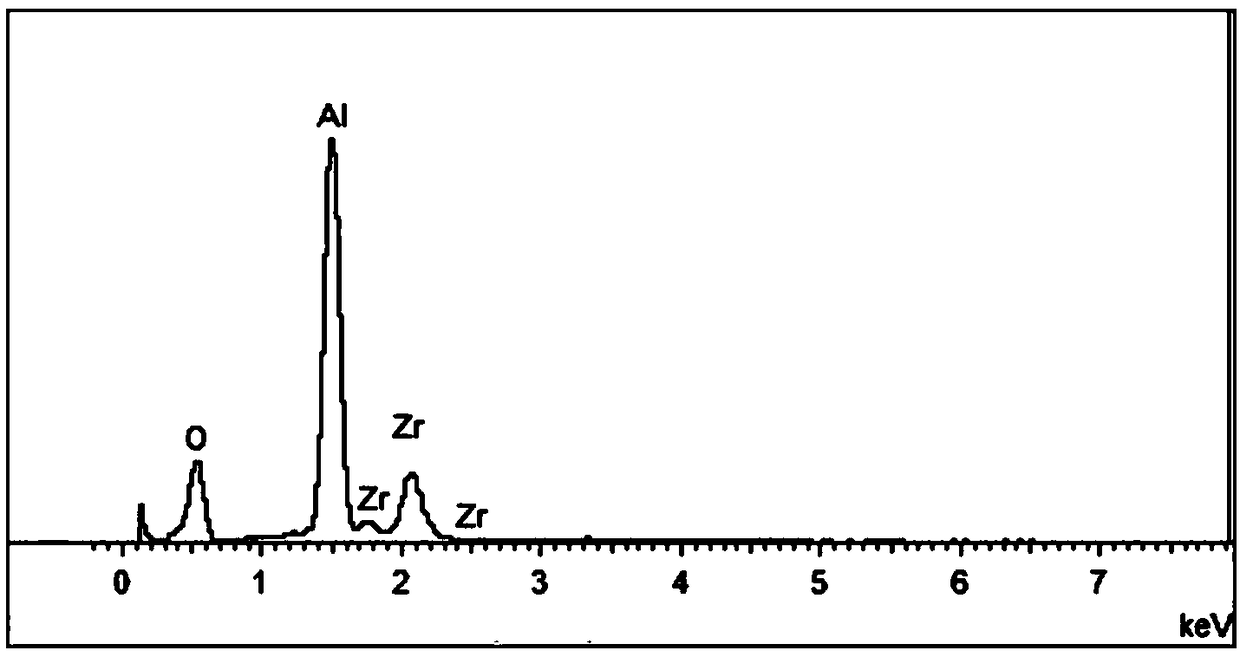

Image

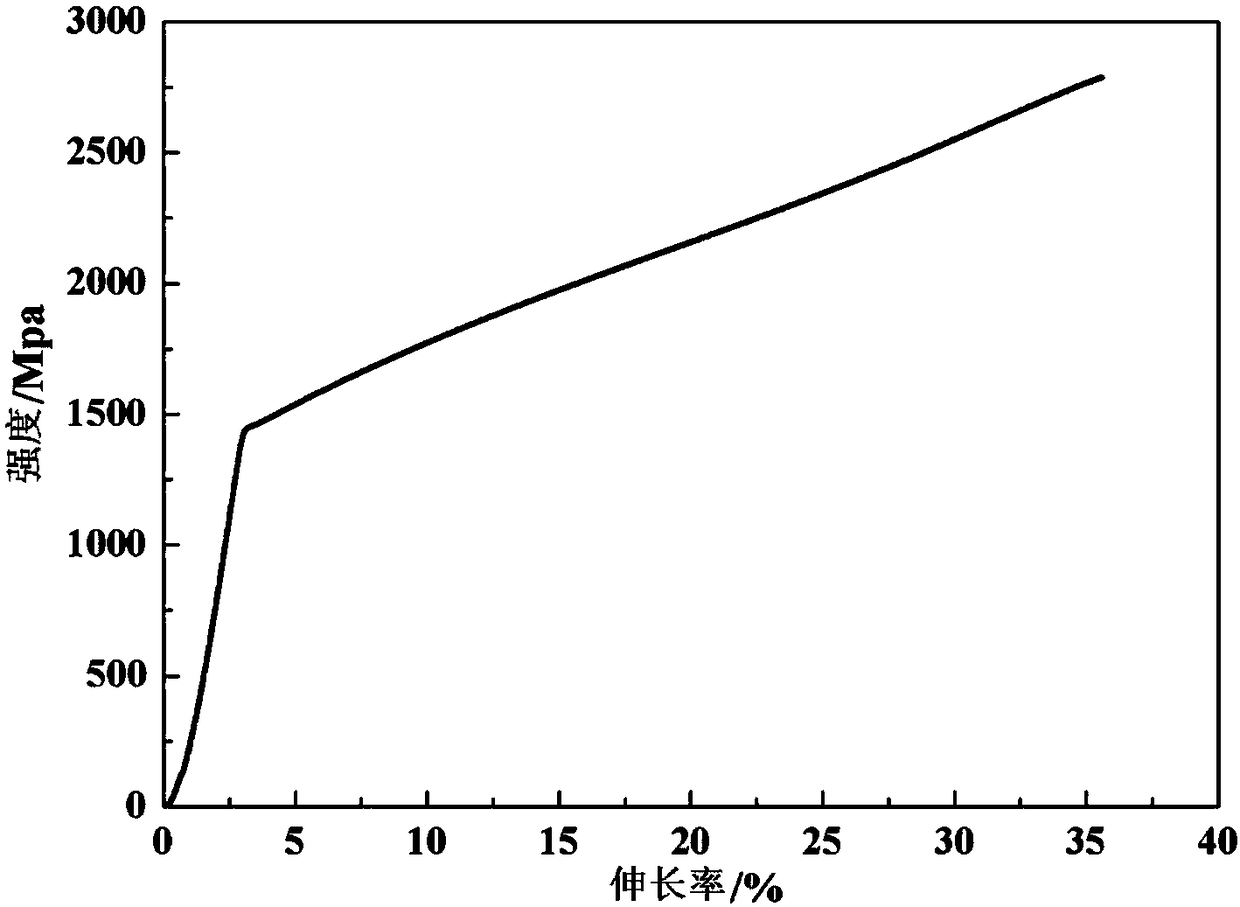

Examples

Embodiment 1

[0032] Weigh 500g of each raw material powder according to the proportion in Table 1.

[0033] Table 1 Raw material formula of tungsten alloy

[0034]

[0035] (1) Pour the powder weighed according to the above ratio into the V-shaped powder mixer, adjust the speed to 25r / min, mix for 10h, and then pour the uniformly mixed powder into the YG8 cemented carbide ball mill tank, and grind it. The ball material is YG8 cemented carbide, the ball milling speed is 100r / min, the ball milling time is 24h, and the ball-to-battery ratio is 5:1; finally, a 100 mesh metal sieve is used to screen the powder after ball milling to obtain uniform composition and no obvious Agglomerated composite tungsten alloy powder.

[0036] (2) Put the composite tungsten alloy powder into the soft sleeve and place it in a cold isostatic press for compression, with a compression pressure of 150 MPa and a pressure holding time of 5 min, to obtain a tungsten alloy green body. The tungsten alloy green body is placed ...

Embodiment 2

[0039] Weigh 500g of each raw material powder according to the proportion in Table 2.

[0040] Table 2 Raw material formula of tungsten alloy

[0041]

[0042] (1) Pour the powder weighed according to the above ratio into the V-shaped powder mixer, adjust the speed to 25r / min, mix the powder for 10h, and then pour the uniformly mixed powder into the YG8 cemented carbide ball mill tank. The material of the grinding ball is YG8 cemented carbide, the ball milling speed is 100r / min, the ball milling time is 24h, and the ball-to-battery ratio is 5:1. Finally, a 100 mesh metal sieve is used to screen the powder after ball milling to obtain uniform composition and no Obviously agglomerated composite tungsten alloy powder.

[0043] (2) Put the composite tungsten alloy powder into the soft sheath and place it in a cold isostatic press for compression, with a compression pressure of 250 MPa and a holding time of 15 min, to obtain a tungsten alloy green body. The tungsten alloy green body is ...

Embodiment 3

[0047] Weigh 500g of each raw material powder according to the ratio in Table 3.

[0048] Table 3 Raw material formula of tungsten alloy

[0049]

[0050] (1) Pour the powder weighed according to the above ratio into the V-shaped powder mixer, adjust the speed to 25r / min, mix the powder for 10 hours, and then pour the uniformly mixed powder into the YG8 cemented carbide ball mill tank. The material of the grinding ball is YG8 cemented carbide, the ball milling speed is 100r / min, the ball milling time is 24h, and the ball-to-battery ratio is 5:1. Finally, a 100 mesh metal sieve is used to screen the powder after ball milling to obtain uniform composition and no Obviously agglomerated composite tungsten alloy powder.

[0051] (2) Put the composite tungsten alloy powder into the soft sheath and place it in a cold isostatic press for compression, with a compression pressure of 200 MPa and a holding time of 10 min, to obtain a tungsten alloy green body. The tungsten alloy green body is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive yield strength | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com