Low-temperature curing type polyester resin for powder coating and preparation method of low-temperature curing type polyester resin

A polyester resin and powder coating technology, applied in powder coatings and other directions, can solve the problems of long curing time of polyester resin and the storage stability of powder coatings needs to be improved, and achieve the effects of reducing energy consumption, good stability and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

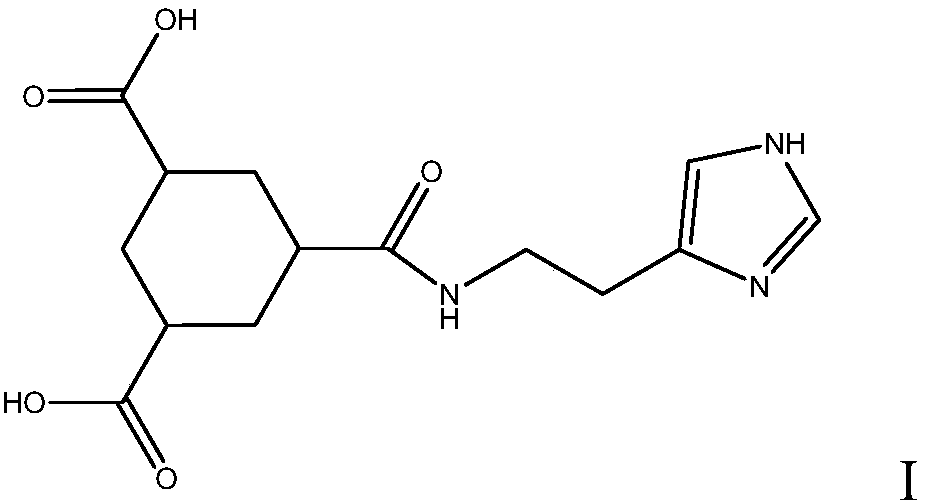

Method used

Image

Examples

Embodiment 1

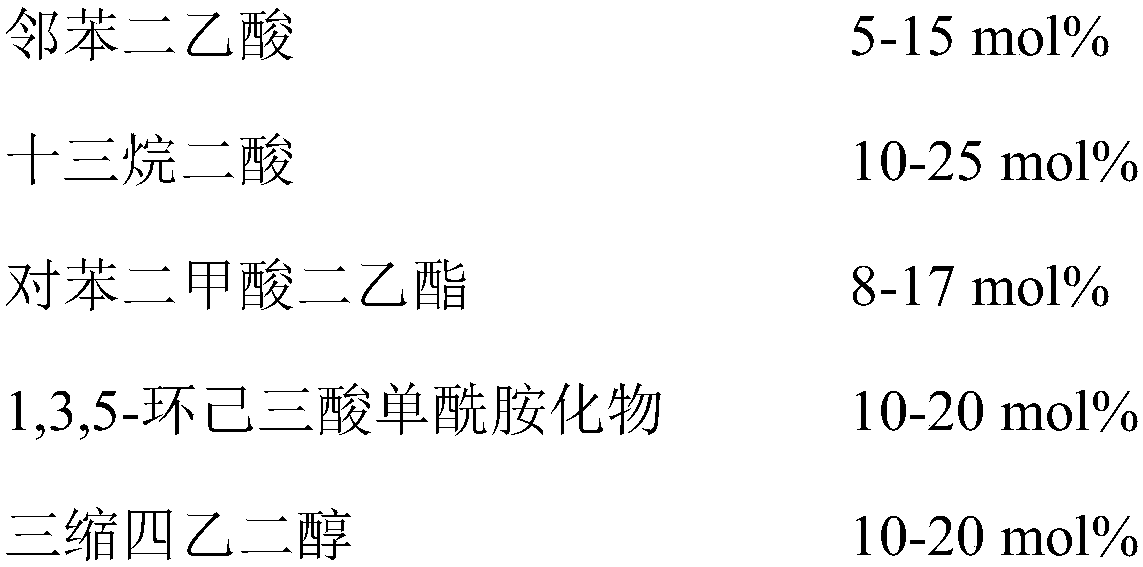

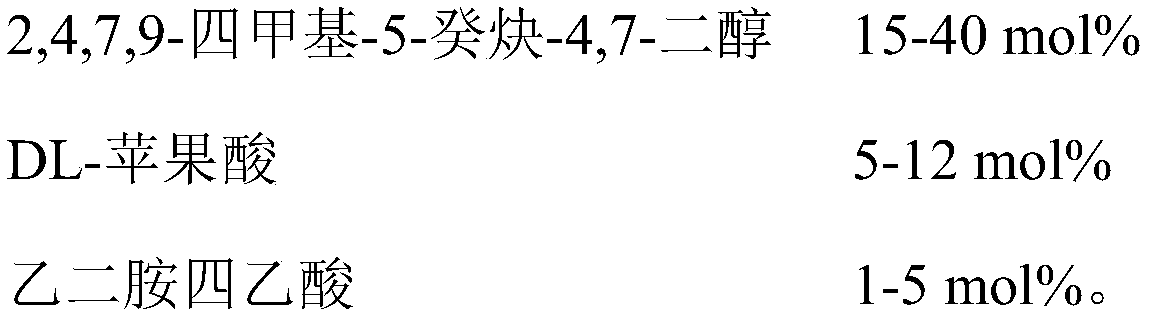

[0058] A kind of low-temperature curing type 60:40 polyester resin for powder coating, its raw material composition and molar ratio are:

[0059]

[0060] The preparation method of above-mentioned polyester resin comprises the following steps:

[0061] A. Add the formulated amount of phthalic acid, tridecanedioic acid, diethyl terephthalate, and 1,3,5-cyclohexanetriic acid monoester into the mixer, and heat and melt at 135°C ;

[0062] B. Add tetraethylene glycol and 2,4,7,9-tetramethyl-5-decyne-4,7-diol in the formula amount to the above mixed material, and add dioctyltin oxide as a catalyst at the same time, Under the protection of nitrogen, gradually raise the temperature to 185°C, then add the formula amount of DL-malic acid, slowly raise the temperature until no obvious distillate is distilled out, and the acid value of the reactant is less than 30mgKOH / g; the reaction temperature should not exceed 245 ℃;

[0063] C, add antioxidant 618 (dioctadecyl pentaerythritol ...

Embodiment 2

[0067] A kind of low-temperature curing type 60:40 polyester resin for powder coating, its raw material composition and molar ratio are:

[0068]

[0069] The preparation method of above-mentioned polyester resin comprises the following steps:

[0070] A. Add the formulated amount of phthalic acid, tridecanedioic acid, diethyl terephthalate, and 1,3,5-cyclohexanetriic acid monoester into the mixer, and heat and melt below 135°C ;

[0071] B. Add tetraethylene glycol and 2,4,7,9-tetramethyl-5-decyne-4,7-diol in the formula amount to the above mixed material, and add dioctyltin oxide as a catalyst at the same time, Under the protection of nitrogen, gradually raise the temperature to 185°C, then add the formula amount of DL-malic acid, slowly raise the temperature until no obvious distillate is distilled out, and the acid value of the reactant is less than 30mgKOH / g; the reaction temperature should not exceed 245 ℃;

[0072] C, add antioxidant 618 (dioctadecyl pentaerythrit...

Embodiment 3

[0076] A kind of low-temperature curing type 60:40 polyester resin for powder coating, its raw material composition and molar ratio are:

[0077]

[0078] The preparation method of above-mentioned polyester resin comprises the following steps:

[0079] A. Add the formulated amount of phthalic acid, tridecanedioic acid, diethyl terephthalate, and 1,3,5-cyclohexanetriic acid monoester into the mixer, and heat and melt below 135°C ;

[0080] B. Add tetraethylene glycol and 2,4,7,9-tetramethyl-5-decyne-4,7-diol in the formula amount to the above mixed material, and add dioctyltin oxide as a catalyst at the same time, Under the protection of nitrogen, gradually raise the temperature to 185°C, then add the formula amount of DL-malic acid, slowly raise the temperature until no obvious distillate is distilled out, and the acid value of the reactant is less than 30mgKOH / g; the reaction temperature should not exceed 245 ℃;

[0081] C, add antioxidant 618 (dioctadecyl pentaerythrit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com